Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

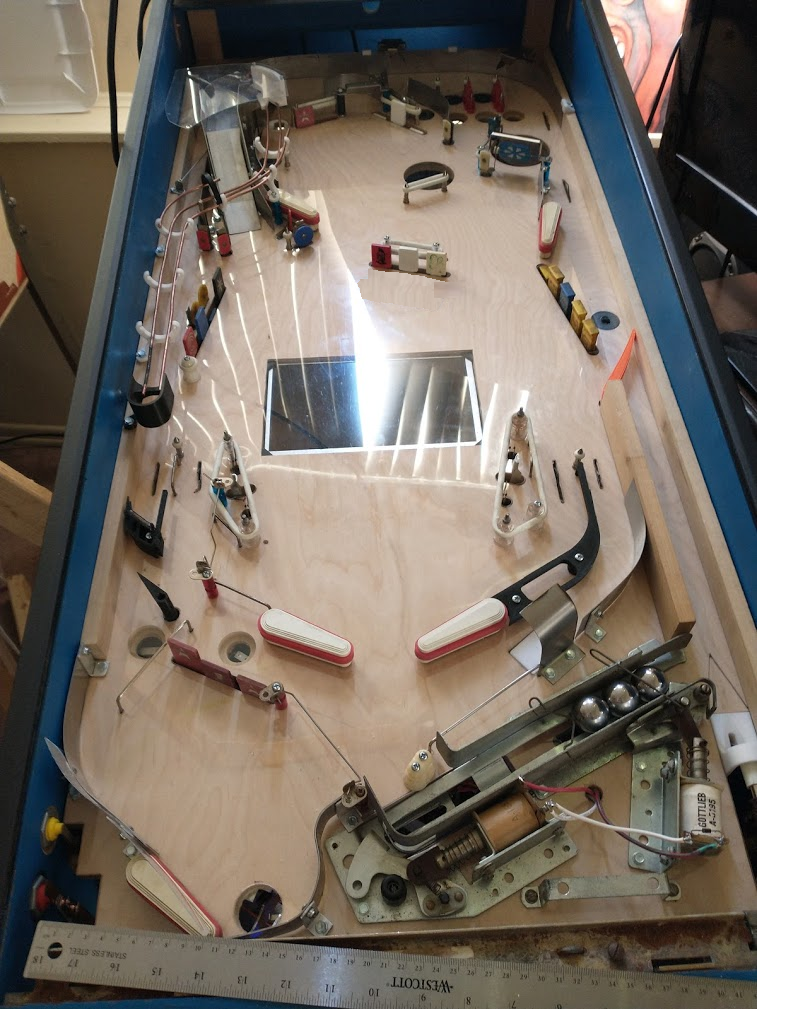

Got the playfield reassembled and have been playing a bunch of test games. No buckling on the main playfield at all. I've got a slight bubble above the upper left flipper, I think I just tightened stuff down wrong though, doesn't seem to be changing. Have to be very careful no screws are rubbing against the edges of their holes, and to attach stuff in a 'wave', to make sure the plastic lies down flat. There's a slight drop in the plastic over the screen from the weight of the ball but not enough to affect its travel or anything.

Plays much faster with the plastic compared to the paper (who would have guessed?). I'm not getting occasional airballs off the center bank, which isn't great, and some balls are flying right over the eject hole. I'll have to make some air ball guards, and might also turn down the flipper strength some, since it's a bit too much in some places. If you hit the left target on the center bank from the right flipper it rockets down the left outlane too fast to see.

While reassembling I also noticed that some of the post screws are starting to strip. Some of these should definitely be machine screws, but that can wait.. for now I'm just upgrading to longer screws, since the ones I had were only going 1/4" into the wood.

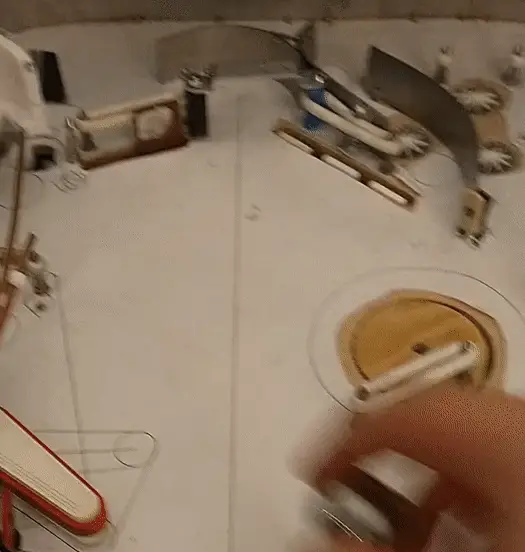

The upper magnet continues to cause me issues. Despite doing multiple tests showing that it could grab a ball from ~2.5" away with no wood in the way, it still can't pull a ball reliably off the post for some reason... It might work better if I had the post above the magnet instead of below, so it'd have more time as the ball drops, but it's probably still be sketchy. Again I wonder if having a large metal core covering this whole area would work better, or if having the magnet under just 1/32" of plastic is equivilant....

If I position the magnet at the far right, it can grab the ball 75% of the time, but it drops it too far to the right and it doesn't feed the flipper well. If I position it more to the left it feeds cleanly, but can't grab the ball. there's about 1/8" sweet spot where it mostly works, but anything can throw it off, definitely not reliable enough.

Additionally, I'm also having issues where sometimes the ball comes around the orbit so fast that it actually bends the post and gets wedged in between the post and the wood on the right, sometimes also lifting off the playfield somewhat. If I can't get the post more rigid, I'll have to abandon it since it's getting the ball suck...

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

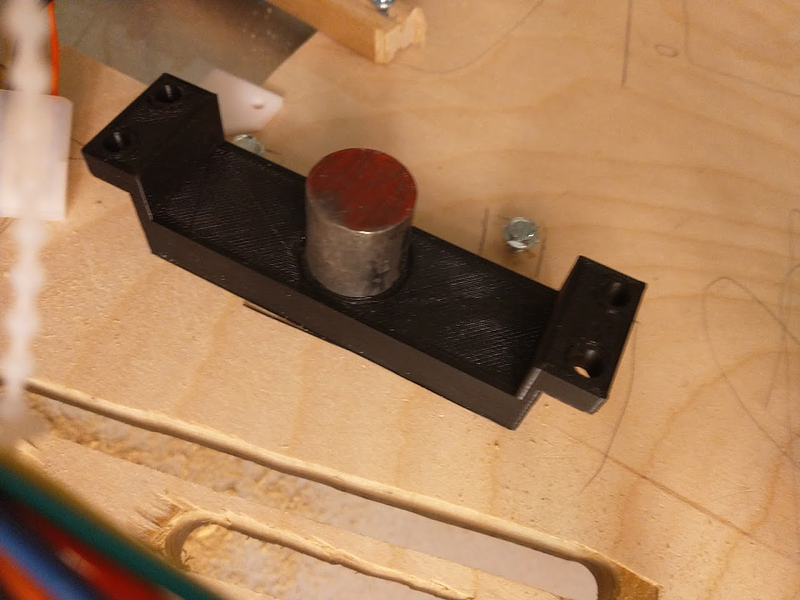

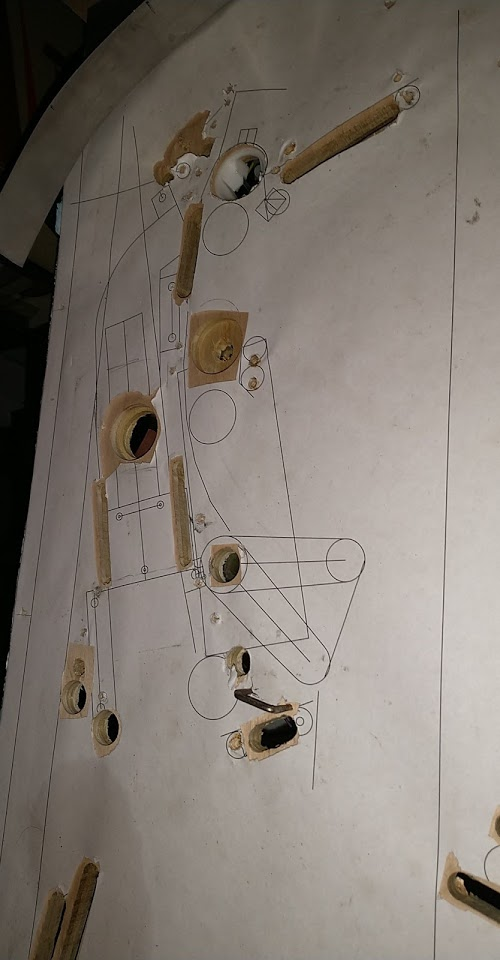

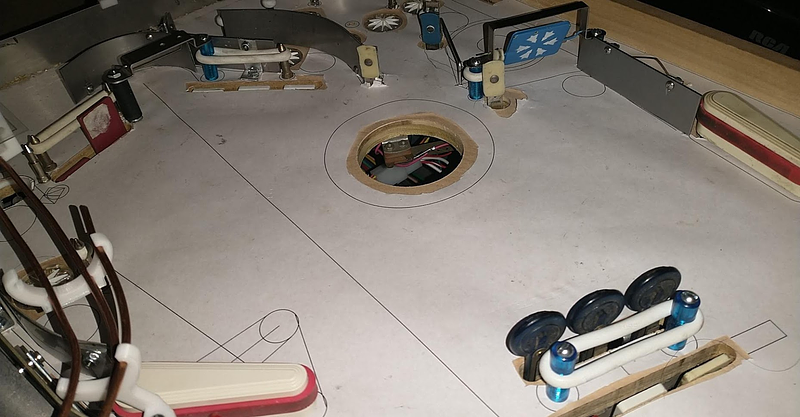

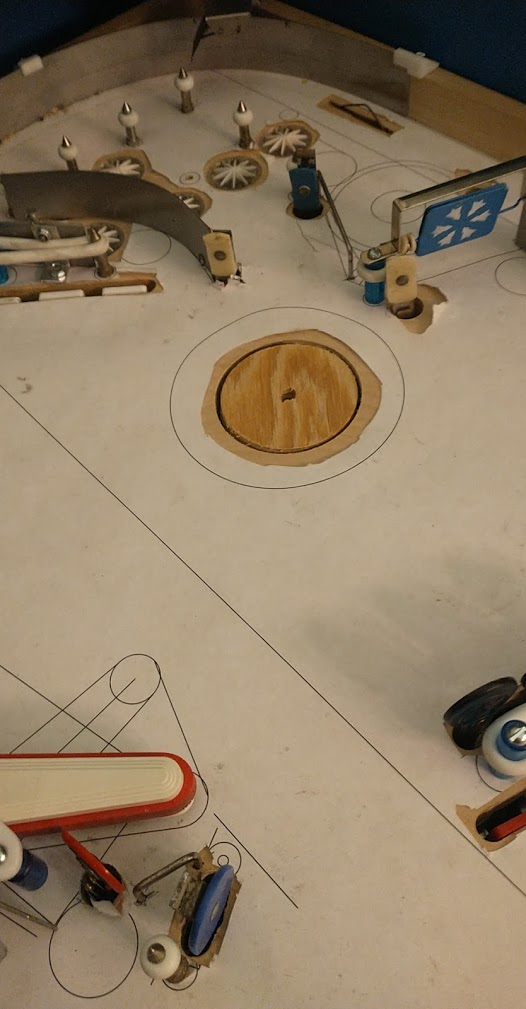

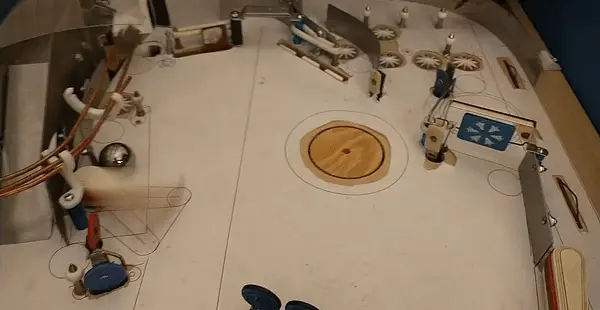

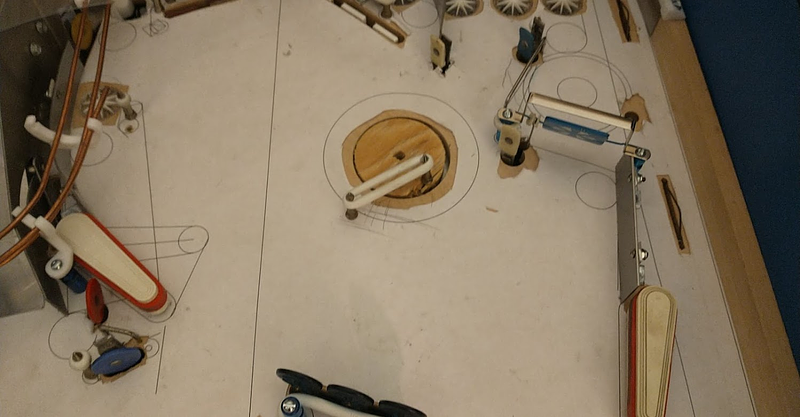

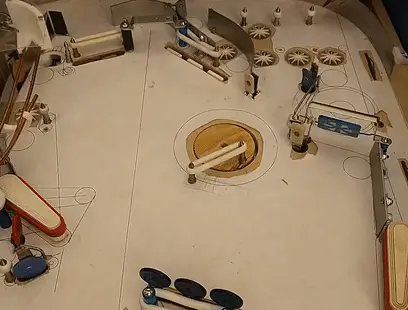

Installed the upper magnet. Needed to cut a 3" hole to fit it, but luckily that just barely left holes for the surrounding stuff that was mounted there. Right below the nearby target you can see one hole where one end of the ball guide goes, which I'm half certain is going to rip apart at some point since there's so little wood left there. Tried to design the mount to hold the magnet slightly below the surface so it won't scratch the plastic, but not sure how that'll work when the magnet is active... maybe I should cut a circle of plastic to 'float' in between them or something? I feel like overall I don't want it to be too much lower, or it may stretch the plastic or something

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

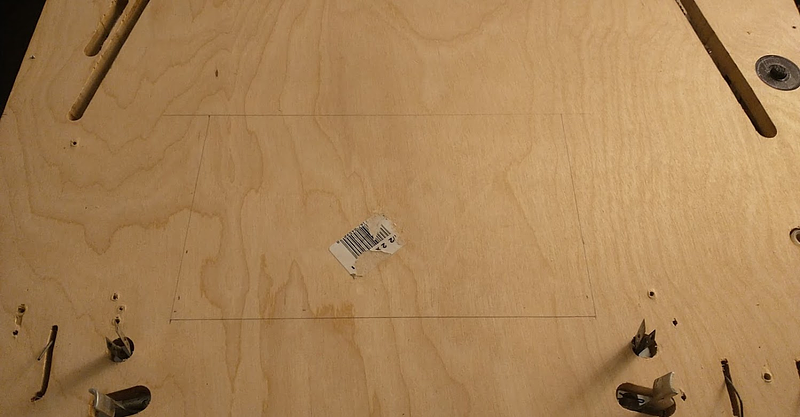

After a lot of careful measuring, it's time.

The fit I'm going for is very tight. I'm about 2mm from one of the drop target mounting points, and I'm going to need to relocate one of the slingshot switches slightly, move a fuse block, and make a custom mount for the magna-save, but, it should work.

Printed this magnet bracket, and cut a small stick of 3/4" iron for the core (I think this is the right metal...)

20 agonizing minutes later, I have a hole

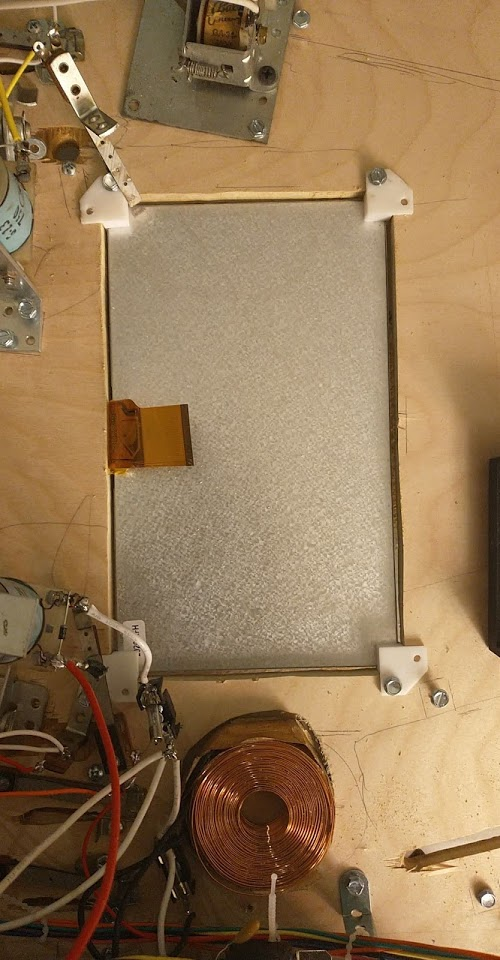

It fits! Barely. You can see the penciled outline of the drop bank on the bottom right, and the currently floating fuse block on the bottom left. I had some room to the top (left side of the playfield) I could have moved it to if necessary, but I wanted to keep it centered between the slings/flippers if possible

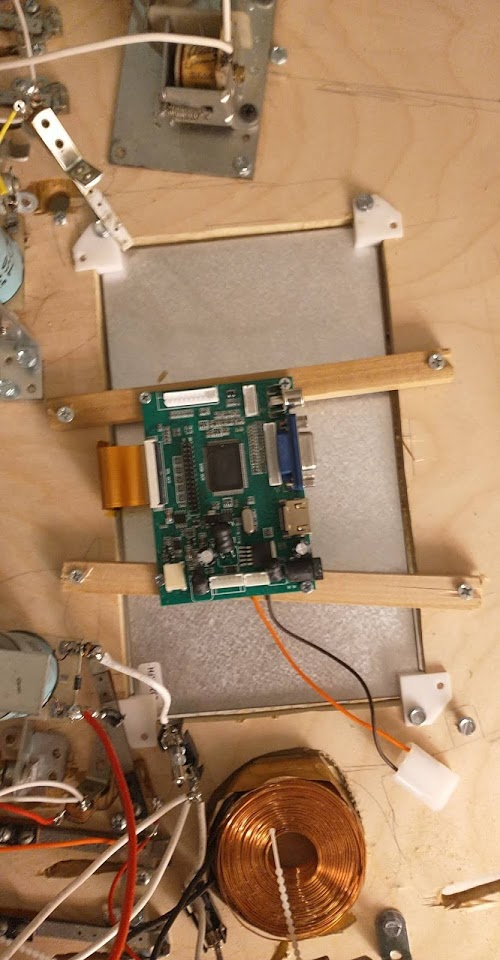

I then mount the control board very professionally , and hook it up. Success!

, and hook it up. Success!

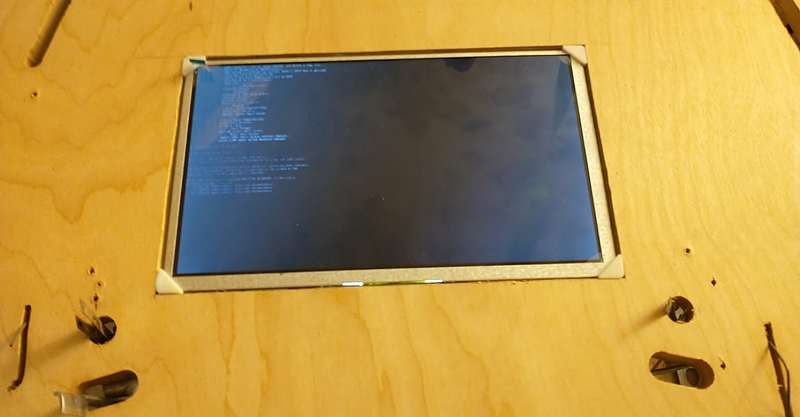

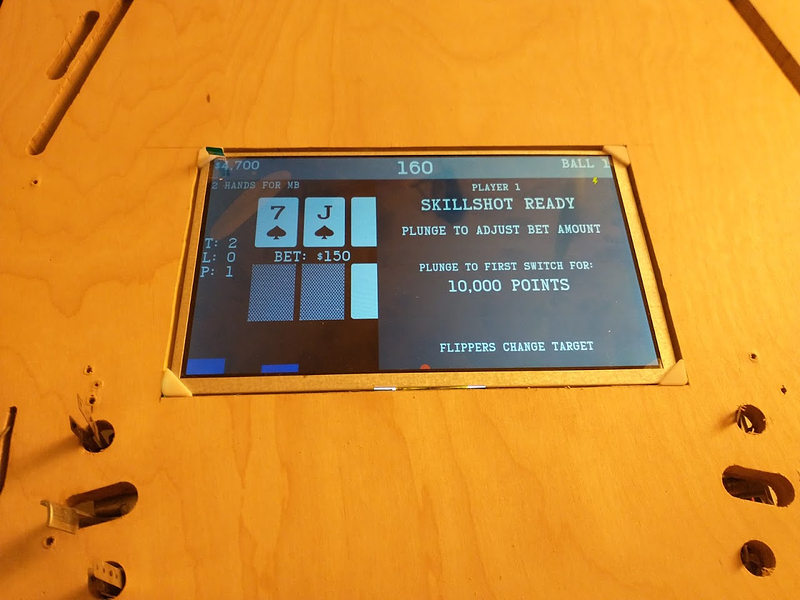

Lets get a game running...

The viewing angles aren't the best but I think it should be okay. Will have to wait until I get it in the game for that though. The supports are a bit too thick and stick out of the playfield, so I'll need to space those or something. Not sure how I messed that up, thought I specifically made them slightly short :/

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

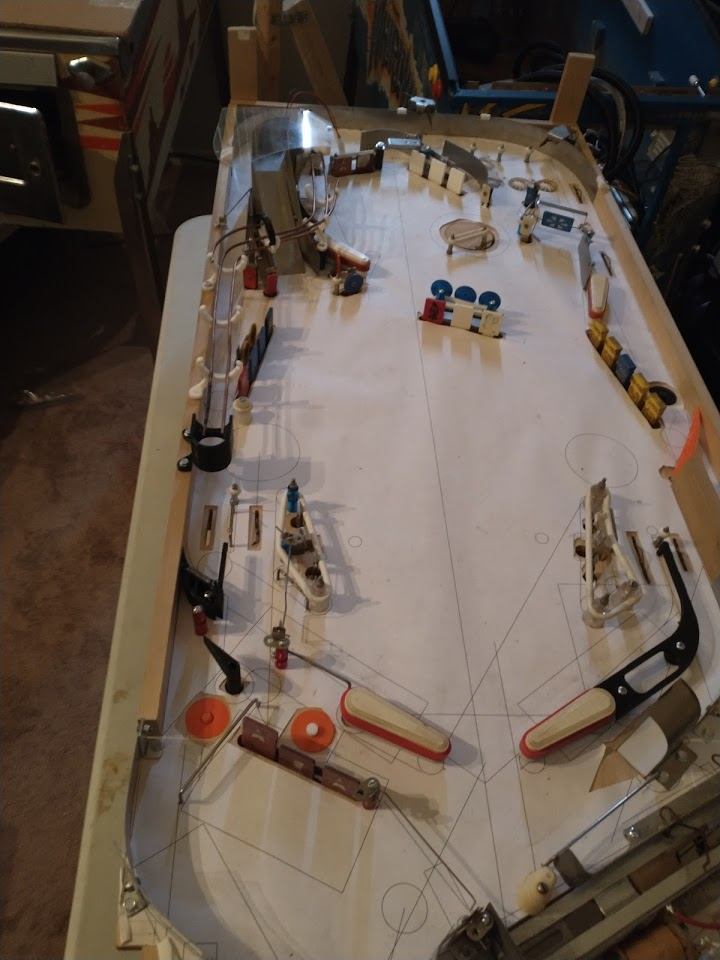

Reassembled and dropped it in the cab again for more testing.

Everything seemed to work fine. No mechs were sticking, no raising of the plastic anywhere. I left it sitting for a while with the transformer+electronics on in case that would trap any heat underneath, but nothing happened. I'm still quite suspicious, but I can't really think of any more testing I can do at this point, and the playfield does look so nice and shiny....

So I took the playfield back out, and disassembled the whole thing again. I'm getting very fast at this, but it's still a pain. One thing I'd try differently next time is the side rails. Currently they're under the plastic, but I think it'd be fine to have the plastic 1mm away from them. This'd save at least a quarter of all the screws I need to remove when taking the plastic off, and prevent the playfield from having time to sag while the rails are removed. Within a few hours of removing them there's a noticeable 1/4" dip in the middle of the playfield, which is more than I'd have expected, especially with all the drop target banks already removed... I assume my playfield wood just isn't as sturdy as what manufacturers use, but nothing I can do about that ![]()

With the plastic removed and everything stripped off, I have some updates to do that I've been putting off:

- the right controlled gate for the top lanes needs to be moved about 1/2" to the left to prevent ball hangups

- the right-most upper lane needs a new rollover drilled in line with the others, since previously it only had a 'bottom' row switch

- need to add lane guides to the upper lanes so the ball doesn't fall the wrong way

- the target under the upper left flipper needs some tweaking. The hole isn't big enough to fit it through right now, so I need to extend it, and I want to reposition the guide wire below it to give a better feed

- I've removed the upper left target (it was sort of under the ramp above the upper left flipper) since it can't be hit due to the pop bumper being replaced with a rubber (it wasn't really hittable before either), so now I can make a new guide going from the upper eject hole to the upper left flipper that doesn't have a gap in it for the target, which will hopefully improve that feed.

- widen a few holes and slots slightly since some mechs would occasionally bind a bit on the edges

Once that's out of the way, I'll move on to the fun part: cutting a 10" hole in the middle of the playfield for the LCD screen. No chances to mess up horribly here, nope... ![]()

And then I can cut another 2.5" hole for the upper magnet and finally get that installed again!

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

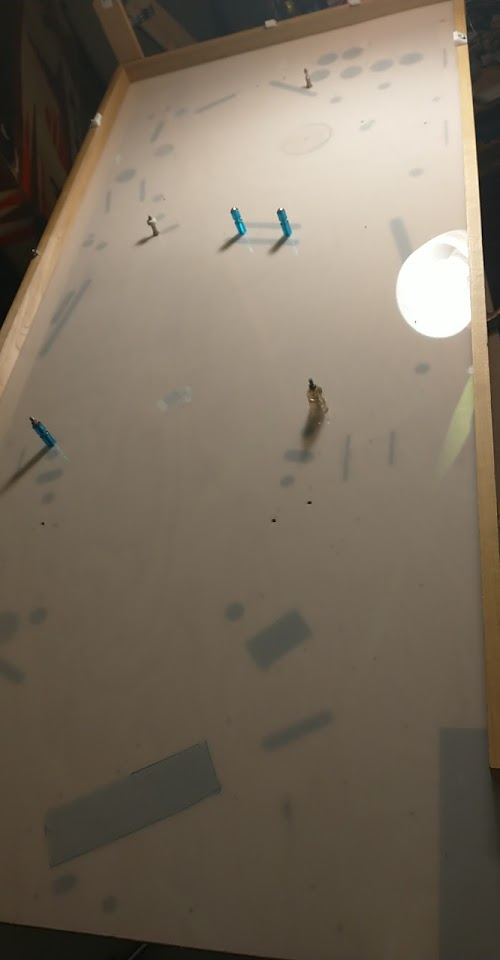

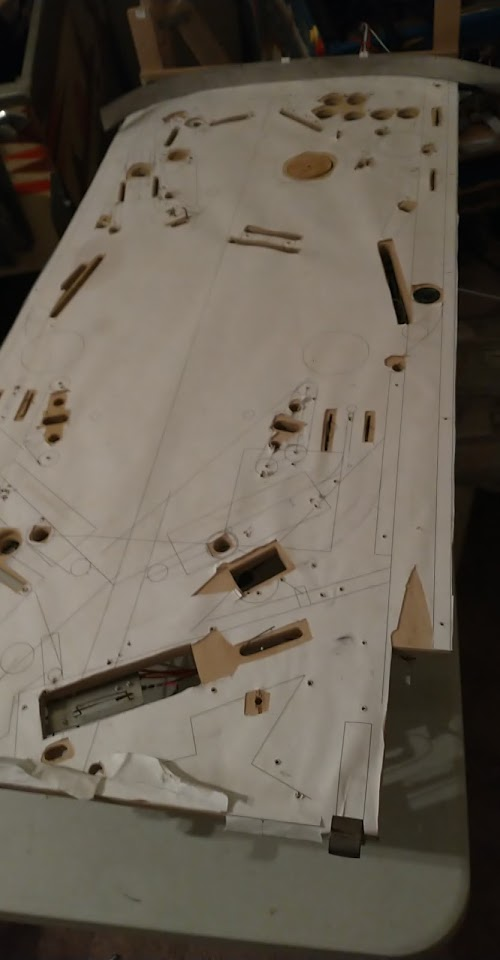

No noticeable change in the plastic after sitting all day with the lights on it, so time to dig in. I started by just making all the holes for posts, guides, etc.

I've gotten pretty good at making clean holes, at least for smaller sizes, but for some reason they never seem to center well. Some I went to a bigger size, others I manually elongated by running the drill against one edge.

Luckily, with a new blade, making the slots and other straight lines isn't too big an issue. I score each side 3-5 times, then use a hammer to punch it out, and I get pretty clean lines (as long as I get the corners right)

Bigger holes cause issues. Once you get to about half an inch (or even 3/8 sometimes) the bits start to chew up the plastic. Depending on how bad it is I can sometimes clean it up with a blade but it's never perfect. I wish I had a better way to do these, but no method I tried (drill, forstner bit, spade bit, etc) was perfect. It'll be fine for a whitewood, but I think I'll definitely need to get a better one of these machine cut at some point if it all works out.

I'm finally at a point where I have most stuff cut out, enough to reassemble and playtest the game to see how everything works. I've skipped some of the guides, the drop target banks (since they're removed right now anyway), etc.

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

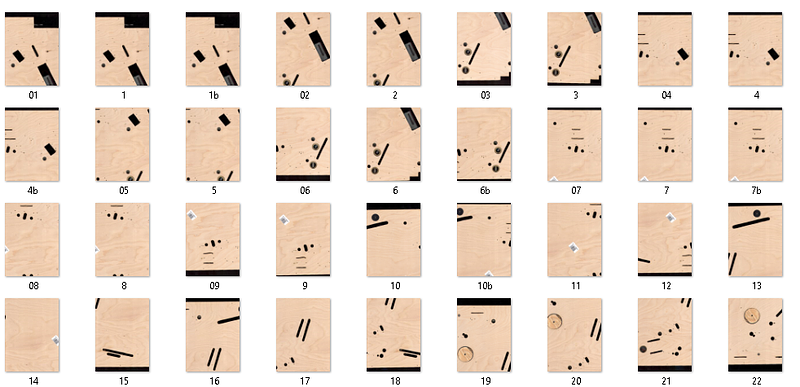

Using my flatbed scanner, I scanned the whole playfield in, since this is probably my only chance to access it completely flat

I'm hoping that I can stitch these together and use them to update my CAD drawing to match the hand-changes I made when assembling, though I've heard mixed results about how accurate this can be...

Then I put down my sheet of plastic, which I think is 1/32 lexan, and started marking holes for posts.

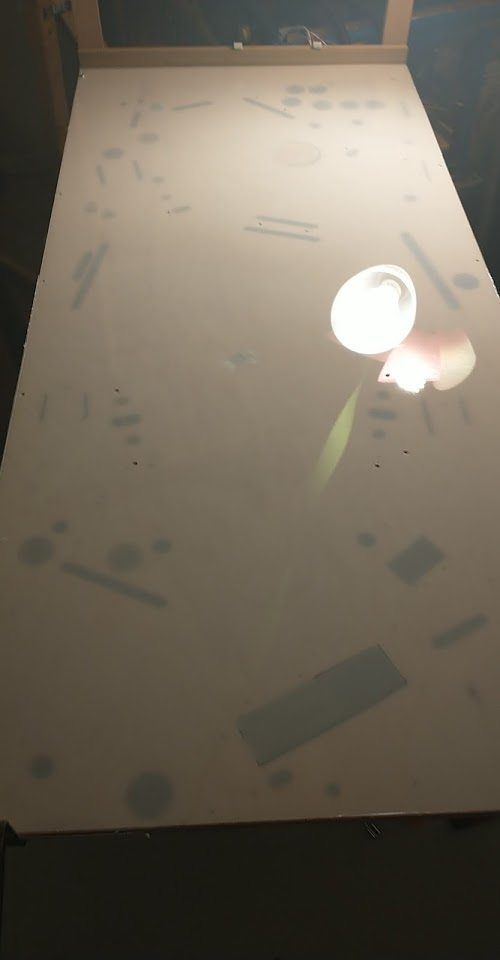

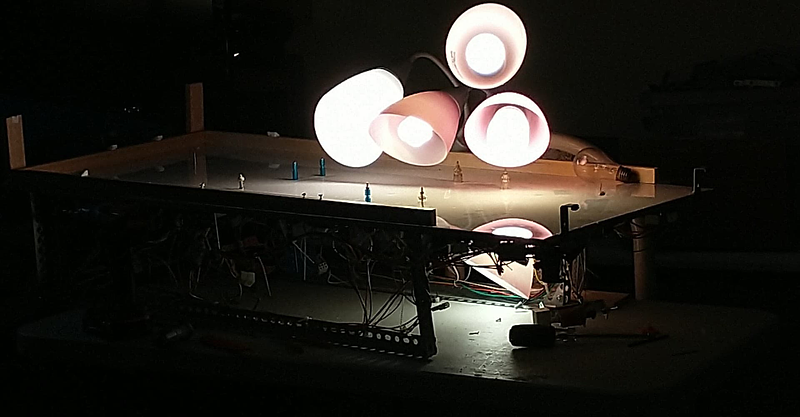

The main worry with this plastic is whether it'll bubble and expand, separating from the wood, which I've seen happen when trying to make playfield protectors. This is a bit thicker though, and lexan, not PET-G; I'm hoping one of those two factors will fix that issue. To test it, the best thing I could come up with is just to heat it up for a long period of time, so I set it up with a bunch of incandescent lamps pointing right at it, for lack of any better options

I'll leave this on all day, and see if the plastic rises up anywhere. If not, I'll proceed with cutting the rest of the holes+slots, and reassemble the game for further testing. Not sure if I'll also cut the hole for the screen at this point, or play it some with the protector first before going 'all in' and cutting a 10" hole in the playfield.

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

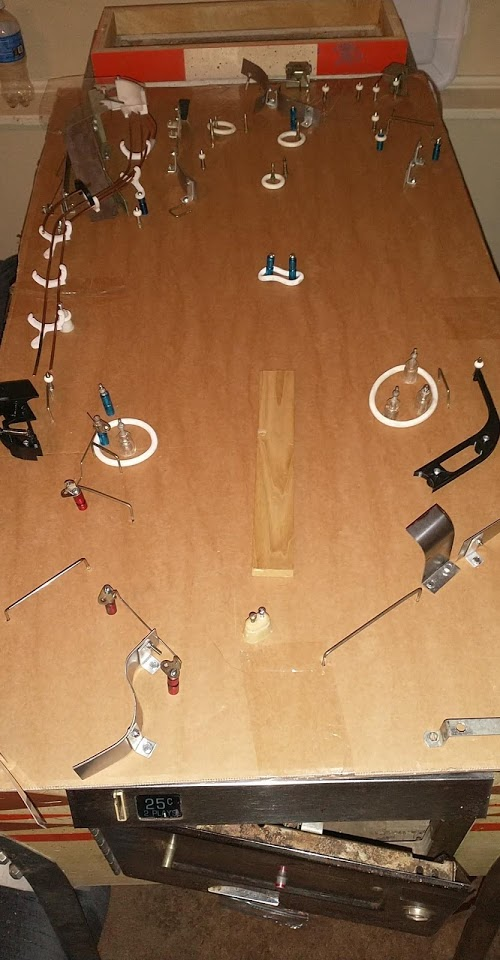

Game is getting increasingly hard to play due to the lack of a screen, so I decided it was time to bite the bullet and try installing the plastic sheet, which means I need to strip the whole playfield. Took it out of the cab for the first time in a while

In some places, I'm glad that past-me thought ahead and installed connectors

In other places, like the wires going to the trough mechs, I wasn't that smart, so I ended up cutting the wires, and I'll install a connector later. A few mechs I left hanging, since I didn't think to put connectors on them, and now they're wired in such a way that I can't easily add them.

Tear down went pretty quick and painless. There's not that much on top of the playfield, and all the drops have connectors so they're quick to remove.

The biggest pain was all the standups. They didn't get connectors either since they're so scattered, and some of them barely fit through the playfield. In a few cases I actually assembled them through the playfield to begin with, so I needed to disassemble the target again to get it out.

The paper has held up pretty well to being played on over and over.

When I first installed it I worried that the ball would rip it up when I started flipping but there's no tears at all, even in high traffic places.

I moved all the playfield components to a spare sheet of cardboard to keep track of them:

I wasn't very consistent about screws, posts, etc when assembling, and in some cases I even had to do stuff like grinding down plastic posts to make them shorter, so you really can't mix and match anything, and keeping it all straight like this is really important.

Taking off the paper reveals about what I'd expected: a ton of trapped sawdust everywhere. It's been messing with the ball and getting it stuck in places it seemingly shouldn't

It also reveals something I hadn't anticipated; the wood around every screw is slightly ripped up and standing above the playfield

I'm not sure if this is just normal, or if it's caused by me screwing everything in without drilling pilot holes. Luckily these sanded down easily without affecting the finish of the wood at all

With the playfield all torn down, next I'll need to start cutting the plastic

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

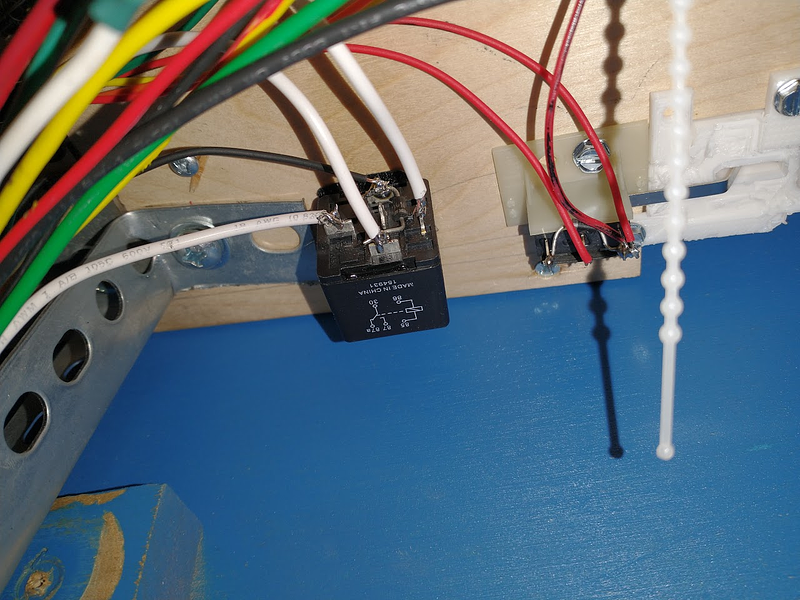

Installed a tilt bob, which had to go on the right side due to how I'd routed the wiring, etc. Even in this position I'm still going to need to trim the rod some to keep it from catching on stuff. Plus I need to earplug it!

With that installed, I realized I still had no way to kill power to the flippers, so I installed some relays too. Now the tilt works properly in game, and the flippers also aren't energized when there isn't an active game.

While opening the game to check on something, I noticed I had four pinballs piled in the front left corner of my cabinet. Occasionally, balls hit by the right outlane saver will airball over the lower left flipper/guide and fall down in there, and rather than grasping around for them I just grab another ball ![]()

So I set up an airball catcher, made from scrap lexan and attached to the existing ball guide

In order to get the height right, I also had to put the glass back in, which was a problem since I didn't have any siderails. I dug a pair of stern side rails (from replacing with lollipop rails) out of my spare parts, and they seem to fit the williams cabinet fine. Eventually I'd like to get proper williams rails on there, but I need to get the secondary holes for the extra flipper buttons, so that's been on the backburner. Since the stern rails are narrower, they fit above the buttons fine.

My lockdown bar is also still covered in rust, so I grabbed one from my whirlwind for now, and for the first time actually had the game assembled with glass+lockdown bar. It's surprising how much of a difference this makes. The game feels much more like a 'real' game. A lot of the noise gets quieted down, which also makes the gameplay feel smoother. A big improvement, although I still need to get a coin door skin somewhere...

With the mechanisms quieted by the glass however, it becomes much more obvious that I don't have any sound effects! I think this is going to be a big focus soon; I need to start finding (or recording) sound effects and callouts for everything. I'm not really sure how I want it to sound either. Most card themed pinball machines are EMs, and the solid state ones fall into that weird early 80s state where the only sound effects that could be generated were laser blasts and explosions (Eight Ball Deluxe always stood out to me for this). By the time sound designers were free to use any sound effects they wanted, poker themes weren't really popular. I think the only two games that'd fit that category are High Roller Casino and World Poker Tour. For better or worse, the sounds on those have never really stood out to me, to the point where I can't actually remember what they sound like to use as a reference. For a while I was tempted to stick a chime box in this game and call it done, but I'd like to try to get some actual sound effects in.

For now, I think I'm going to try to make all the sound effects be related to actual poker. Chips clinking, cards being shuffled, etc. Not a ton to work with but maybe it'll be enough. Not sure how that'll feel as a pinball game either though....

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

After more playtesting, I decided that it was too hard to catch the ball. With a game where not hitting the wrong things can be as important as hitting the right things, players need to be able to get some control. Even I was having trouble with this, and would often have the ball roll off the end of the flipper while trying to catch it, which I think is partly due to how steep my flippers are (at rest), and thus how shallow they are when raised.

When I originally designed the game I tried to copy the layout of my Alien Star, but I messed up somehow, and part of that was that I put in my flippers too steep. A while ago I picked up a spare gottlieb inlane guide, so I stuck this in my printer and took a scan:

measuring that picture, I got an angle of 119 degrees (probably 120 in reality since that's a nice number...), while my layout was 126 degrees (fun fact, williams inlane guides are 125, so I somehow mistakenly made williams inlanes...). So I made a new inlane guide with a 120 degree angle:https://cad.onshape.com/documents/cf8933508c54fdc1d2e1cbec/w/8de46f8a59b2e2a9657a1015/e/ce2603cfd473c1490421177c

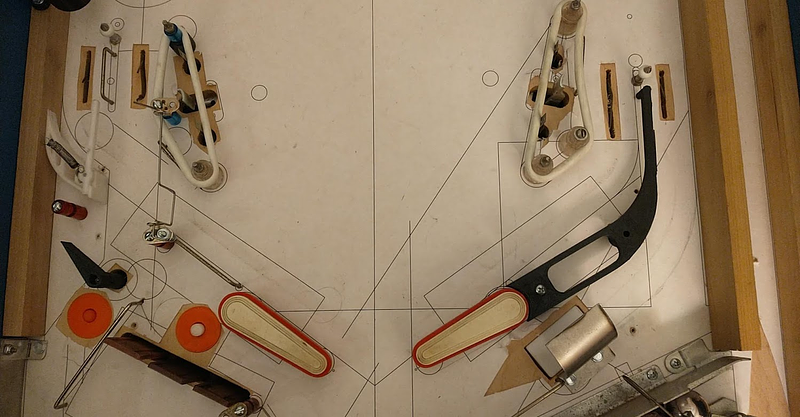

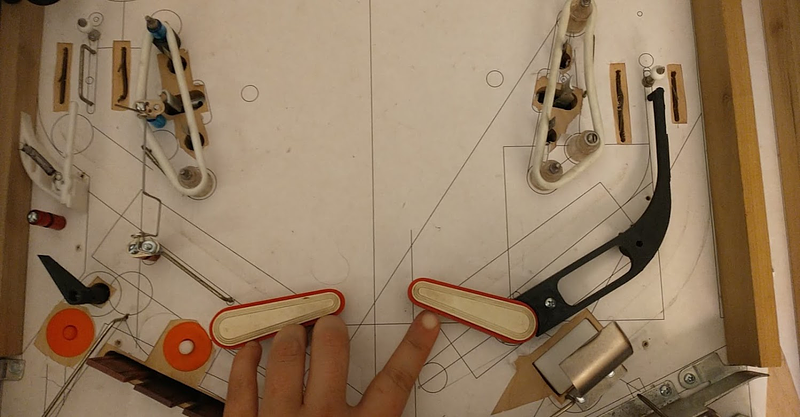

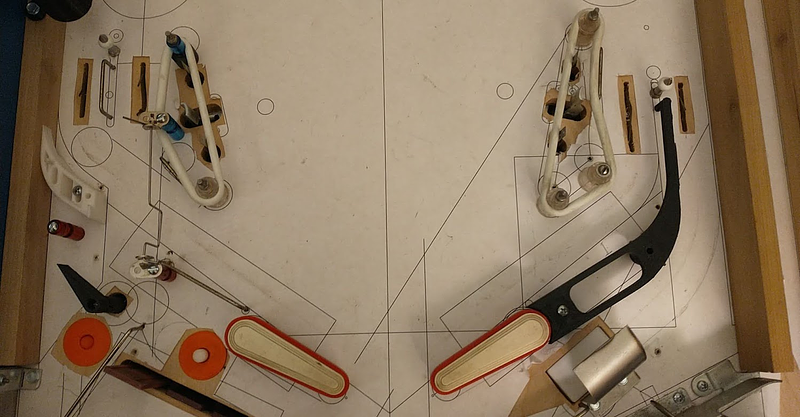

Installing it on the playfield made it look way more dramatic than it was, with the giant gap between it and the slingshot:

But the actual difference in the flippers was pretty reasonable:

So I went ahead and adjusted the left side as well, and moved the slingshot down to compensate

You can see from the old lines and holes how much stuff moved... I'm ending up with a lot of holes in my playfield! When I try to make the plastic for this, I'm going to have to be careful to note which holes are 'current' so I don't use the wrong ones when reassembling.

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

For the second aspect, I wanted to see whether the shot behind the pop bumper could be made if you removed the pop bumper. So I took out the pop bumper:

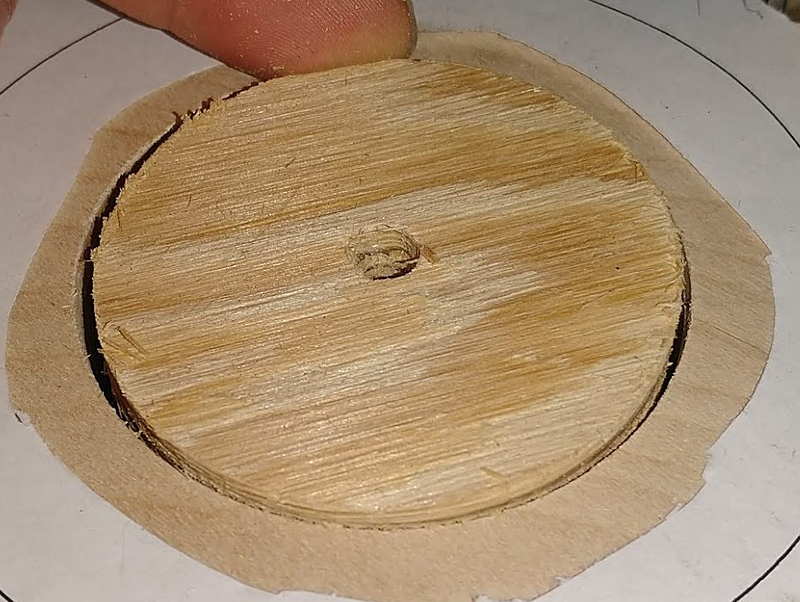

Gobble hole? No, I need to fill it. What do I fill it with? Well, lets just cut another hole with the hole saw and save the piece

Not a perfect fit, but for testing it works better than expected.

Now... Can you shoot into that area to the right of the back lane?

No problem!

Originally I was going to consider redesigning the lanes area to add another 'shot' here if this angle worked, but I realize there's already a handy blue target right there, that can no longer be hit by the pop bumper, so I don't really need to design any new shots. Just add an arrow insert pointing at that target and make it a jackpot or something, and it goes from 'least useful target in the game' to 'major shot'. Considering the amount of work necessary to redo this area to use two shots instead, I'm inclined to just go with the four lanes from the previous approach and this 'shot' here.

Now for the last bit, should I put something where the pop bumper was? I did a bunch of test runs, dropping the ball from each of the upper lanes, rolling it down the metal guide, shooting it from the upper right flipper, to see exactly where the ball traveled, what angle it was going at, etc, and then took a deep breath and installed two posts.

This is another case where I hate trying to place stuff, since getting these two posts positioned at the proper location and angle to get the bounce I want could take a lot of trial and error, leaving my playfield filled with holes, but I don't really have any better ideas on how to approach it. Originally I'd hoped that both ends of the rubber would be located on my disk I installed, so I could just replace it if necessary, but it was clear from my drop tests that at least one end would need to be on the playfield.

Now... does it work?

Success! I'd like it to feed a bit higher on the flipper, but proof of concept is working good. I think eventually it'll need be lowered a bit (but not so low that it obstructs the right flipper's path to the upper scoop. A bit of nudge when the ball lands on the rubber should help too. Before fine tuning further I'm going to play the game more and see how this affects other parts of the game, but throwing it around by hand it seems to be working generally how I'd like:

I had also planned to maybe put a standup behind this rubber to be hit by the right flipper, and it looks like from a very early shot you can hit the bottom edge of the rubber, so that does look possible, but I'll wait to do that until I'm sure I like this rubber and its placement. I might also experiment with alternate coil stops/etc on the right flipper to make it shoot at a higher angle.