Search

Showing Posts Tagged

P3,

but not

P1(Click any tag to remove it)

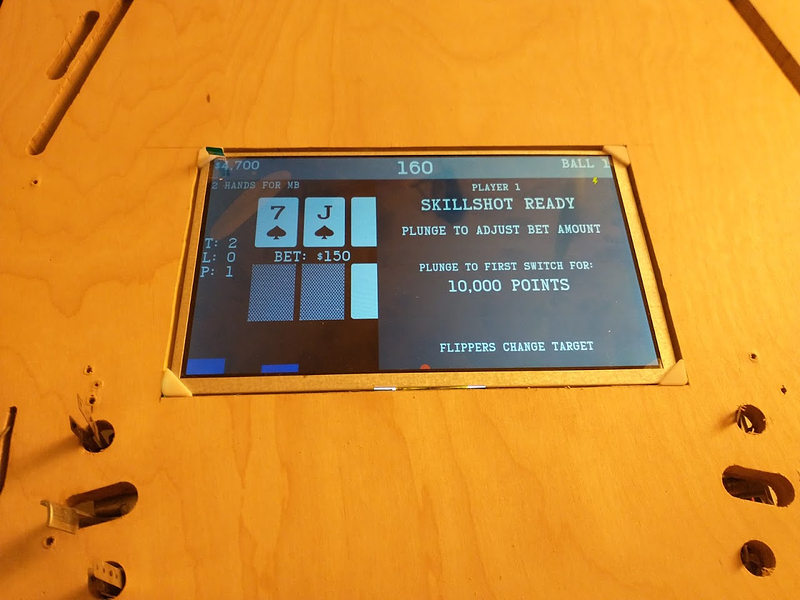

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

Overall, the game got approximately 400 plays at the show.... I think. Before folding it up for transport, I also coded in a bunch of audits and stuff so that, for every game played, it'd store a big data file full of stats, timestamped, for me to dig through later. By counting those files, I reasoned, I could get the play count easily. There's just one problem: it turns out the RPi doesn't have an internal clock. Whenever it boots, it gets the current time from the internet. And there was no internet at pintastic. So when that happens it just picks up where it left off, meaning that the first games played on Friday were timestamped at some time Wednesday when it was last connected to the internet, and the games on Saturday look like they came right after the ones on Friday, so I have no way of actually knowing exactly which games were played which days. I tried to reconstruct everything as best I could, so I think my numbers are pretty accurate, but it's annoying that I don't have perfect results...

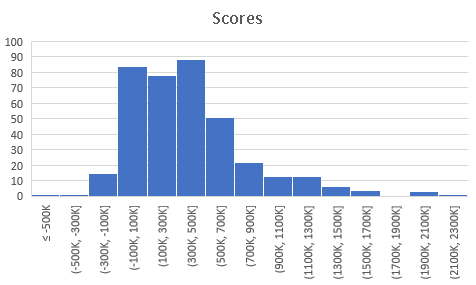

Anyway, some fun stats:

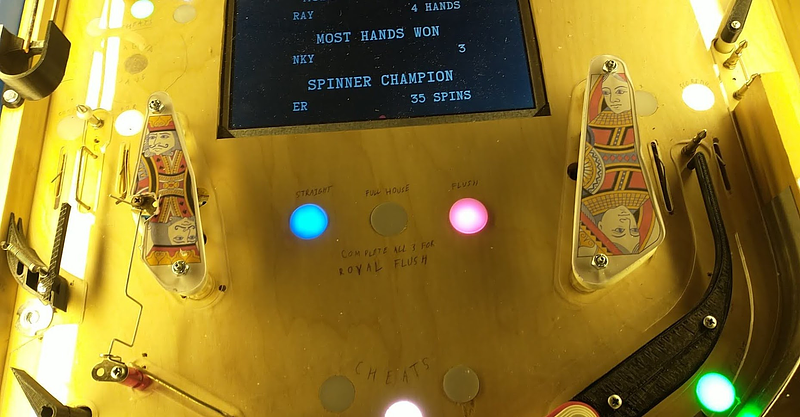

- Total Games: 382. Of those, 345 were single player. 28 were two player, and a few three and four player. No one did a five player game ![]()

- Top score: 2,297,380, by 'OLP'. Congrats, whoever you are!

- Lowest score: -584,410. Even more impressive. I've never seen someone get half that low of a score. Sadly no initials were given for that game

- Average score: 400k. Pretty good. When I started writing the rules for the game I wanted 1 million to be obtainable, but not a 'gimme'. You should be excited when you get a million points! I think my balancing has done pretty well on that front.

- Scores over 1 million: 32. That's about 8%, which would also put the 'replay' score right around there too, nice

- Most money lost: $4810

- Most money won: $5880, again by OLP. They must have been good at poker... This cash in also got them the 'Top Cashout' high score at 1,542,850. More than half their score from poker!

- Most hands won: 4. 4 is a pretty good game... I think the max I ever saw someone get during testing was only like 9, and they were familiar with the game and concentrating on just winning hands.

- Most hands played: also 4. So whoever played that 4 hand game had a 100% win rate, wow!

- Average cashout: 140k. This is slightly off since I realized that I had a minimum cashout of zero, meaning that anyone who lost points is going to be counted as just a zero, bringing the average up, but I don't think it'd affect it that much. Considering that the average score was 400k, I think this number is pretty well balanced. Maybe it should be a tad higher? I don't want the game's scoring to all come down to the end of game cashout, but also, it's Poker, you know?

- Average bonus: 50,000. This feels a bit too high to me, considering an average game is 400k. Almost half people's scores is coming from bonus? I'll probably have to tweak this a bit lower.

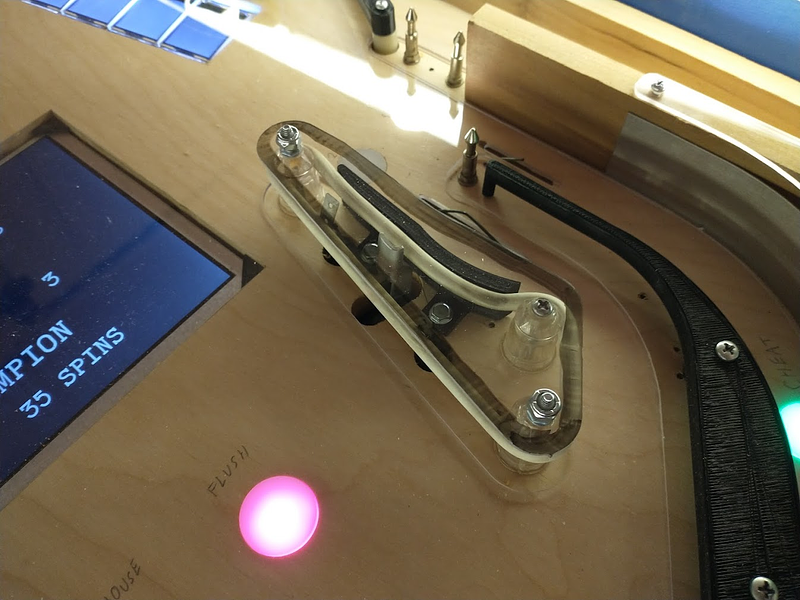

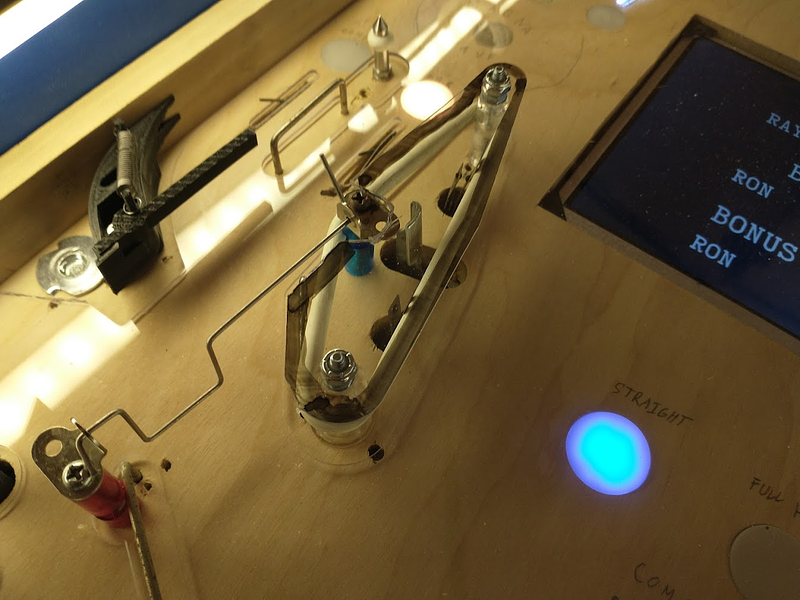

- Multiballs played: Hand: 84, Straight: 13, Flush: 10, Full House: 12. Nice to see that the three main multiballs all had similar play counts, but the discrepancy between 'Hand' multiball (the 'gimme' multiball for completing your first hand) and the rest is a bit higher than I'd like. When watching people playing, I noted a ton of people were lighting multiball but then not starting it. At first I worried they didn't know how to start it, but even when pointing it out, they still couldn't do it, so I think really the ramp shot is just way harder than I thought it was. I wish I'd made an audit for 'multiballs qualified' vs 'multiballs played', I'm sure it would be quite depressing

- Flubbed multiballs: 68. Also depressing... 68 of the 119 multiballs played scored zero points! I guess people just forgot to flip or something? There's no ball save so I know the multiballs can be short, but I'd expect most people to at least get to bat the ball around a bit. Similarly, not a single person got a jackpot in Straight multiball. I'd thought that one was easier than the jackpot for full house, but one person did get a nice 700,000 point jackpot from full house

- Most skillshots made: 7. That's a pretty good number. Again, I think the high ever was only around 9. Sadly this is counteracted by...

- Zero skillshots made: 232. That's not single skillshots either, that's entire games played where the player didn't make one skillshot. More than 50%.

- Biggest spinner rip: 58 spins. The average spinner rip is only around 20, so that's really amazing. Maybe they managed to combo it and get two hits in?

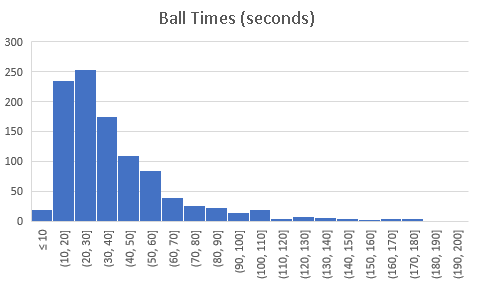

- Ball Times:

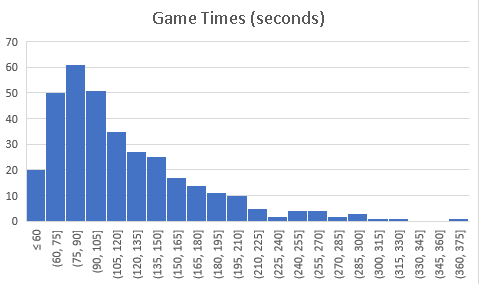

- Game Times: these were a bit lower than I'd hoped. I think optimally a game should last around 3-4 minutes, but the majority were shorter than 3 minutes. I'd put a lot of thought into trying to make the game easier for less skilled players, but couldn't come up with that many ways to do it without making it easier for more skilled players. A timed ball save would probably help here by just inflating the minimum possible ball time, but I'm not a big fan of them in games where you can plunge directly to a flipper, AND have savers on both outlanes to help you...

- Average poker hand win/loss: 1.47/1.05. Not bad. I guess at least some players are trying to play the poker a bit, otherwise I'd expect an even distribution

- Right outlane ball save used successfully: 68 times. Sadly this number isn't that useful without a 'number of right outlanes' audit, but it's nice to know that 68 people got to have the 'saved the ball using the popper' moment. When watching people play, this is probably the most exciting, successful moment that I saw

- Ramps shot: 99. Surprisingly low across 400 games, but people just seemed to have a ton of trouble lining up this shot for some reason.

And finally, all my audit data, zoomed out to fit on screen ![]()

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

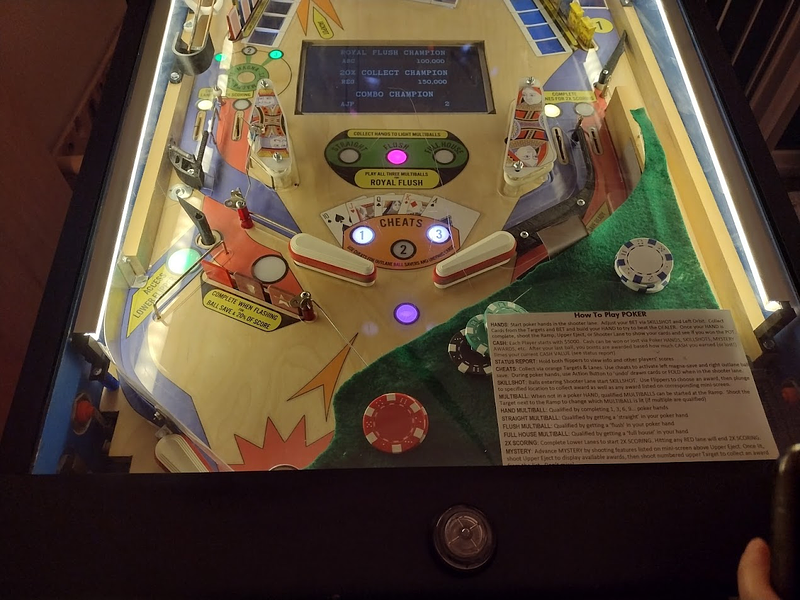

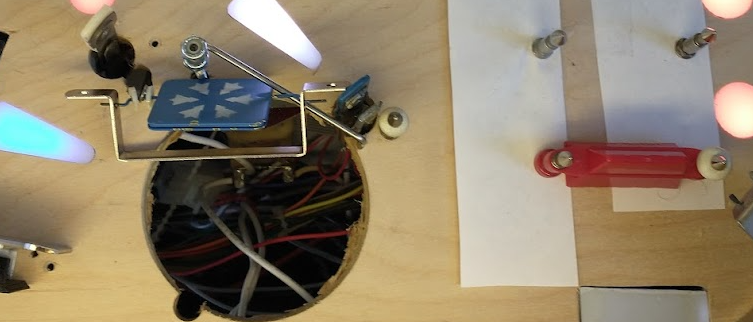

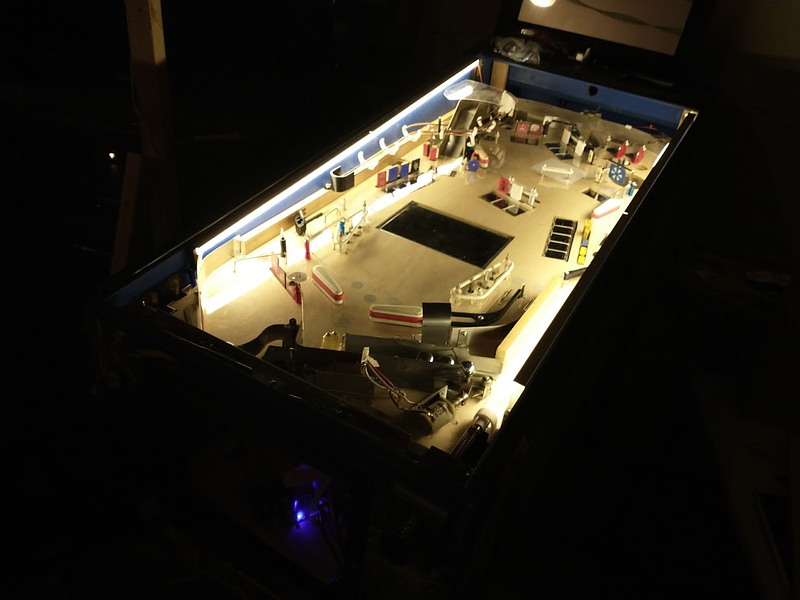

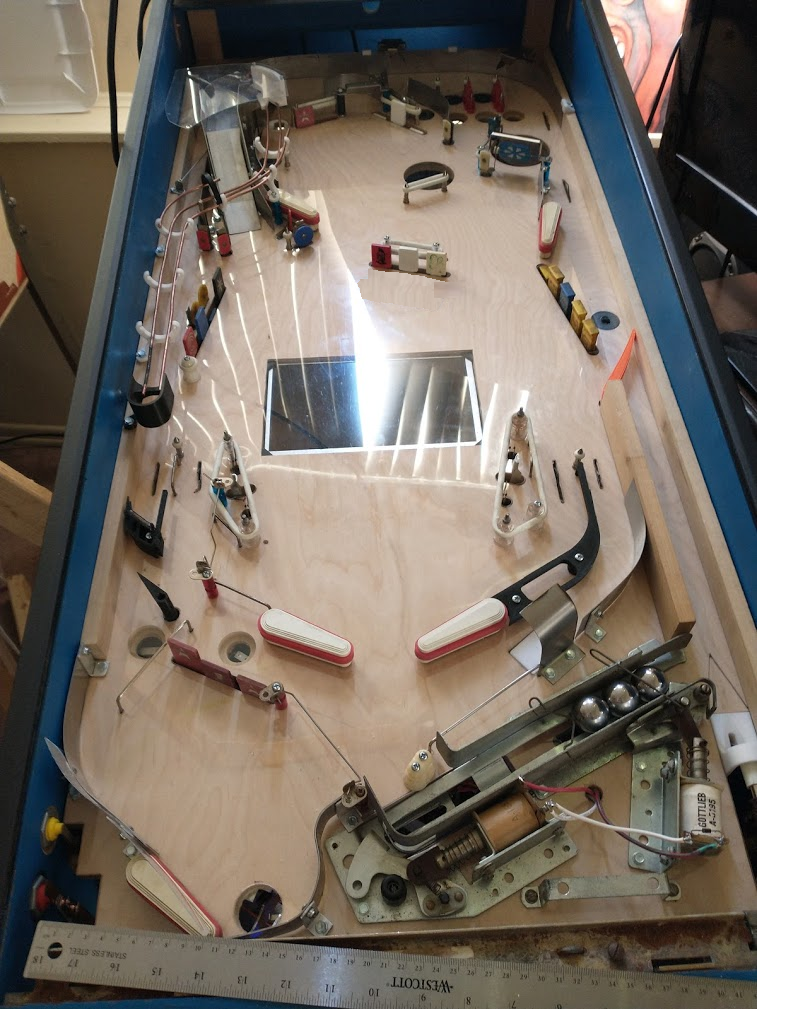

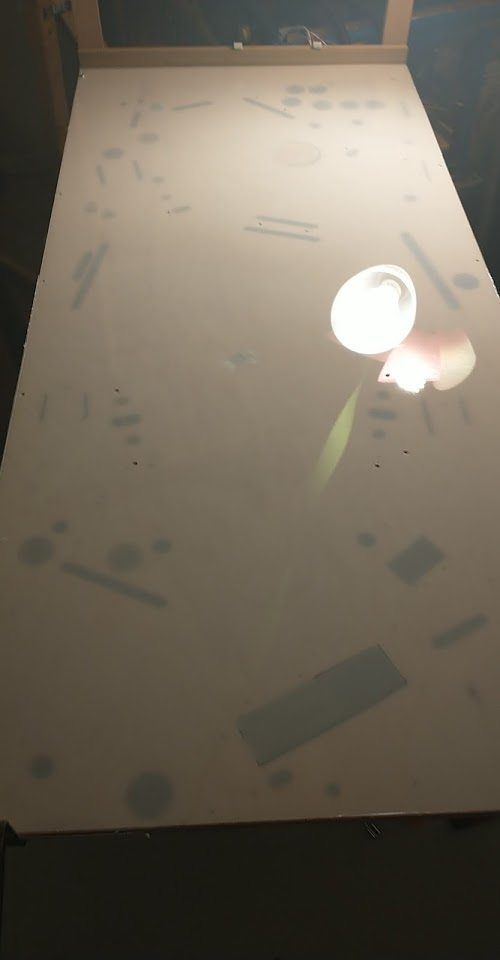

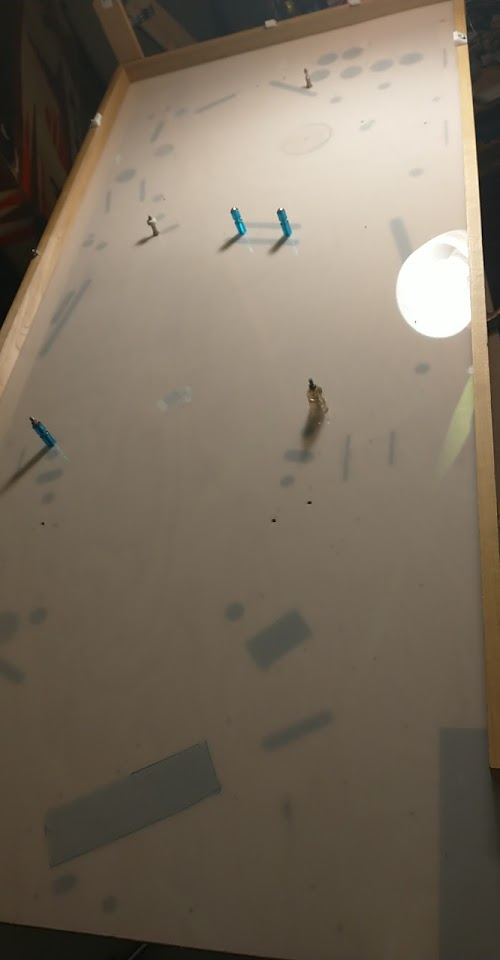

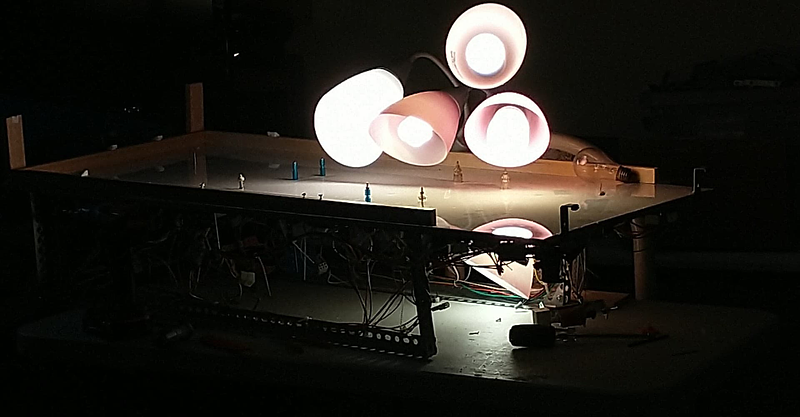

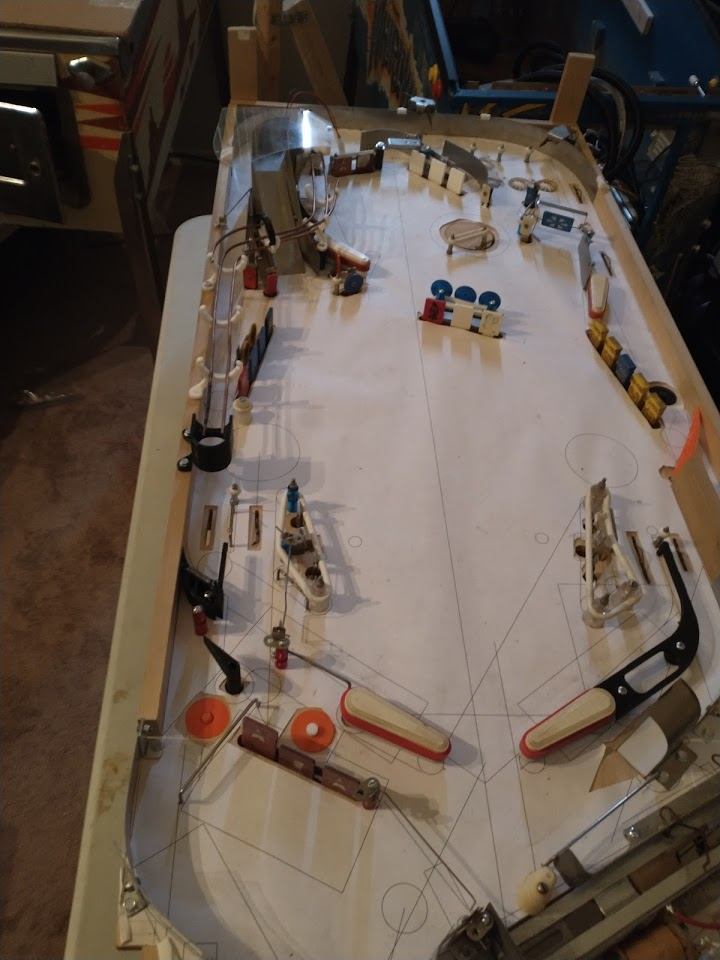

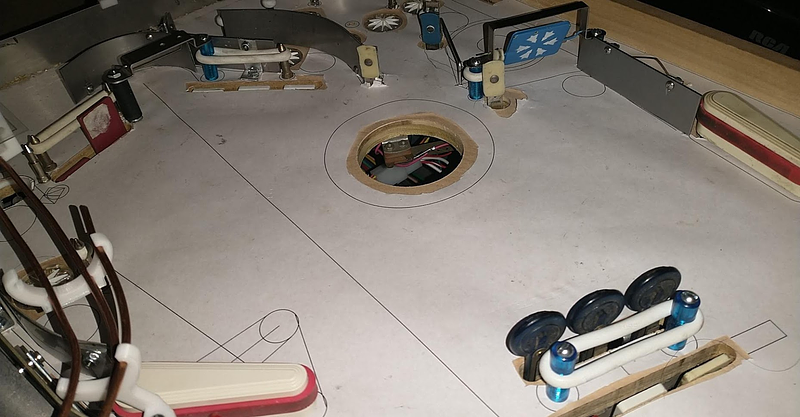

Heading to pintastic, I was mainly worried about three things: broken 3d printed parts, ball sticks, and something going up in smoke. I arrived early Friday morning and set the game up in the free play area:

A quick inspection showed that everything had survived the journey intact, except that the upper 3 bank of drop targets had nearly worked its way lose from the playfield somehow. I'd never seen it come loose at all before, so this was a bit of a surprise, although considering that, for various reasons, it's only held in by two screws, I probably shouldn't have been so surprised. If any bank was going to do it, it'd be this one. It was at this point that I also discovered I didn't have any half inch, #8 wood screws, which I'd bought specifically to replace loose #6 wood screws (which is what I used for everything on this game) with in exactly this sort of situation. But I did have 3/8", and I reasoned that the thickness was probably more important than the length here, so I installed those. A few test games, and a quick chat with the creator of the Pincraft homebrew who walked by, and then I reset all the high scores and pronounced it "good to go" and left to check out the seminars.

I came back a half hour later to check, and the game was... still working! Had a few nice chats with players, and got a quick interview done by a youtuber, and then I left again. I tried to check on it every half hour or hour or so throughout the days, but I wasn't planning on really being there the whole time and sometimes I didn't get back for 4 hours at a time.

Issues encountered, day 1:

- about an hour in, I came back to check on it, and it was turned off! Uh oh, what could have happened? So I turned it back on and it all worked fine. No idea why someone turned it off, and didn't try to contact me

- soon after, I got a text that there was a part loose on the playfield. Turned out to be a random 1/2" wood screw. I searched all over the game but couldn't locate anywhere missing the screw, so I just tossed it in my spare parts and closed the game up again

- another text, another part loose on the playfield. This time it was the spring off my left inlane gate. There's nothing holding this on besides gravity and friction, so I'm honestly surprised this had never happened before but, more than a year of testing and it didn't, so I never worried myself about improving it.

Oh well. I put the spring back on and we're good to go

- came by, a player was trying unsuccessfully to start a game. "Ball Missing". Oh boy, we finally have a ball stuck! I confirm there's only 2 balls in the trough. Search high and low all around the playfield... no ball. I finally find it in the coin box area, sitting right on top of one of my boards, but no damage luckily. No clue how it possibly could have gotten down there.

- another part on the playfield. it's the spring again. I reinstall it.

- game has crashed. The cause? No space left on the SD card; my debug logs have filled up the entire 32GB. I sorta knew this was a possibility, but besides from turning off the logs I hadn't found any good solution since I can't delete the old logs while the game is running easily. I delete the logs and restart the game, problem solved.

- another part on the playfield. it's the spring again. Grr. I wonder if maybe the spring has gotten stretched out over time, and replace it with a new one. Maybe the extra tension will hold it on well enough?

- while showing the game to someone, I notice that the left outlane diverter gate is stuck down. Did the mosfet blow? Nope, it's being PWMed properly to stay down, so the driver board software is working properly. The game software thinks it shouldn't be engaged though. Something must have gotten out of sync between them, so I restart the software and it resolves the issue. No idea how long it was like that, but the coil still hadn't gotten hot, so I guess my PWM settings must be pretty good. I'd considered just having the gate stay down during play (vs turning when the outlane switch is hit) but had been worried the coil would eventually cook, so I'd avoided it. Might be worth another look since I've been having issues where the gate doesn't turn fast enough to divert balls

- someone reports a stuck ball. hopefully it's not in the cash box again. nope! It's... stuck on the left inlane gate. the new spring is just strong enough that a very slow ball isn't heavy enough to push the gate open. I try to stretch the spring a bit and find a happy medium between the two and cross my fingers

- finally, near the end of the day, I again get a stuck ball reported. This time it's sitting in the outhole, and not getting kicked over. I worry there's a switch issue, but it turns out the coil fuse for that bank has blown. I replace it and get ready to turn the power off quick once I see what's locked on but the game works fine. Not sure what blew the fuse. Looking at it, it's a fast blow, 4A. In retrospect that probably should be a slow blow to account for random situations where too many coils just happen to fire at once, but it's never been a problem before, and I'm wary of swapping fuses at the event, so I put another 4A in.

Day 2:

- while showing the game to @McSquid, the left drop target bank starts having trouble resetting. Luckily, my code will retry a few times and then give up, so it's not a huge deal, but after the game I check it out and see that it's starting to come loose like the 3 bank did the previous morning. Again, this is a bank where I had to remove one of the 4 mounting brackets to make it fit, so maybe that's a problem, but there's not much I can do about it. I swap in some #8 screws just in case

- a few hours later I get a report that the game is 'stuck'. When I get there it's sitting on the bonus collect screen, but not counting down. Somehow, the bonus 'total' that's supposed to be awarded has become NaN, which basically means a divide by zero or something happened somewhere. The game keeps trying to subtract 1,000 from the total and give it to the player, but when you subtract something from NaN you get... NaN. Not sure what caused it, but a reboot fixes it.

- a couple more uneventful hours pass, and the NaN bug strikes it's head again. Weird that this didn't happen on day one, but twice on day two, but nothing I can do about it right now

- another part on the playfield. it's the spring again. I reinstall it. Looks like this will just be a thing for now. I'll try to make a new version of the gate with some little overhang to hold it on in the future

- around 8pm, the fuse blows on the outhole again. Still no idea what's causing it, but again just replacing the fuse fixes it. I suspect that maybe the left outlane gate (which is on the same solenoid bank) might be stressing out the fuse when it gets stuck on, and that combined with some other coils may be blowing it?

And that's it! Not a single broken 3d printed part. No smoke. Not even any real ball stick areas for me to address. The game was received pretty well; a lot of praise for the lower flipper and the right outlane VUK/popper once I explained it.

That's probably my biggest 'failure'/takeaway from the weekend though... Most people didn't pick up on any of the more advanced features/rules I'd worked in while playing. A lot of people got confused by the secondary flipper buttons for the magna save and popper, and I'm reminded sadly of the new Black Knight's action button magna save. Not many people actually picked up on how the poker hands worked, or at least, they didn't have the flipper skills needed to actually aim at good cards. Most people just flailed around at the targets and got random hands, then double flipped through the 'end of hand' animation without even noticing if they'd won or lost. Also, very few people figured out the skillshot. Most just full plunged, which tended to send the ball flying all the way around to the left inlane to their surprise. I thought I'd done a pretty good job of making the skillshot obvious, flashing the lights brightly, etc, but apparently that wasn't enough. It's a bit saddening to see, but I guess that's just how a lot of players are. I don't really plan on changing anything on that front though; I didn't design this game with the 'mass market' as my goal. When possible I've tried to make it so the layman player can also enjoy the game as much as possible, but I'm not going to remove features that expert players can enjoy just because they may slightly confuse other players.

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

Finally got the game set back up again after its trip to Pintastic, so an overview of the past few weeks...

I didn't want to mess with the functionality too much since things had seemed mostly solid, so once all the art was done, I tried to focus on finishing touches.

I wanted to cover up the apron since it was just a clear piece of plastic and a bit ugly, so I had the random idea to just use green felt like on a poker table. And what goes on a poker table? Chips!  These are just super-glued together, but they're holding up alright. With the lockdown bar and instruction card on, it doesn't stand out too much

These are just super-glued together, but they're holding up alright. With the lockdown bar and instruction card on, it doesn't stand out too much

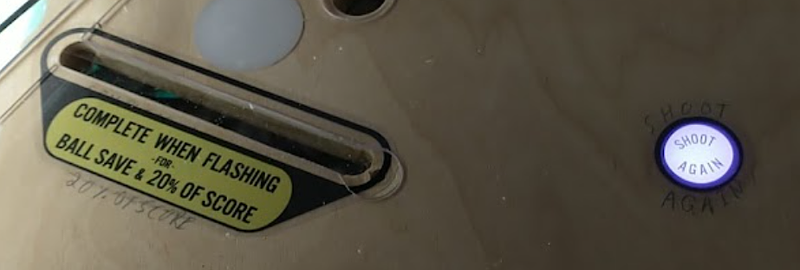

At the request of a tester, I added a quick shooter gauge. I would have liked to use an existing one from a game with some nice art, but none fit the weirdly shaped bottom corner I ended up with...

And, as a last finishing touch:

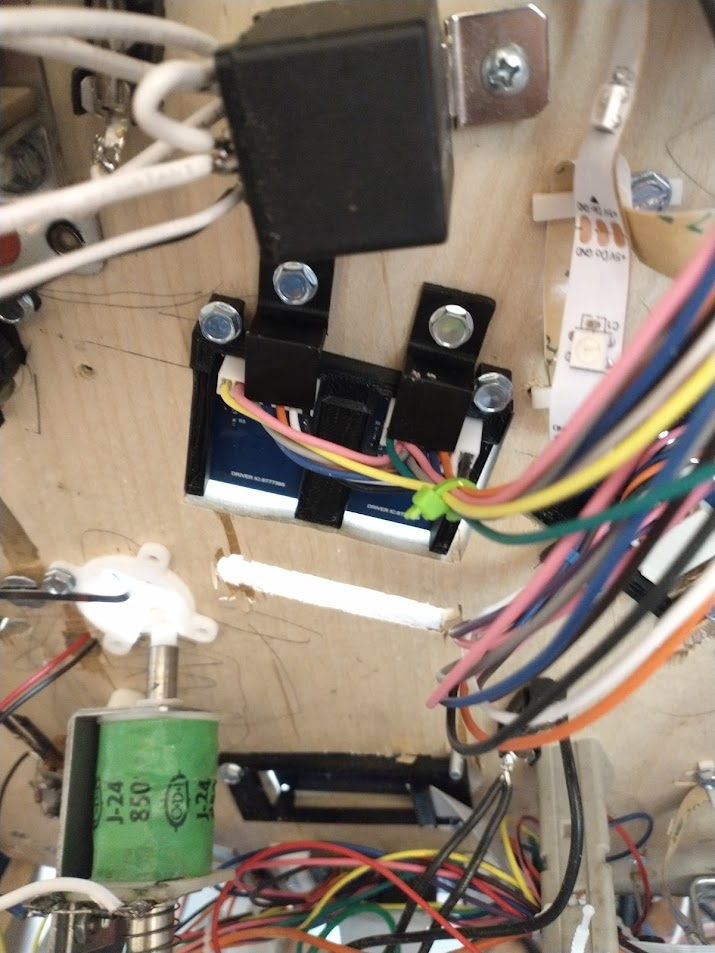

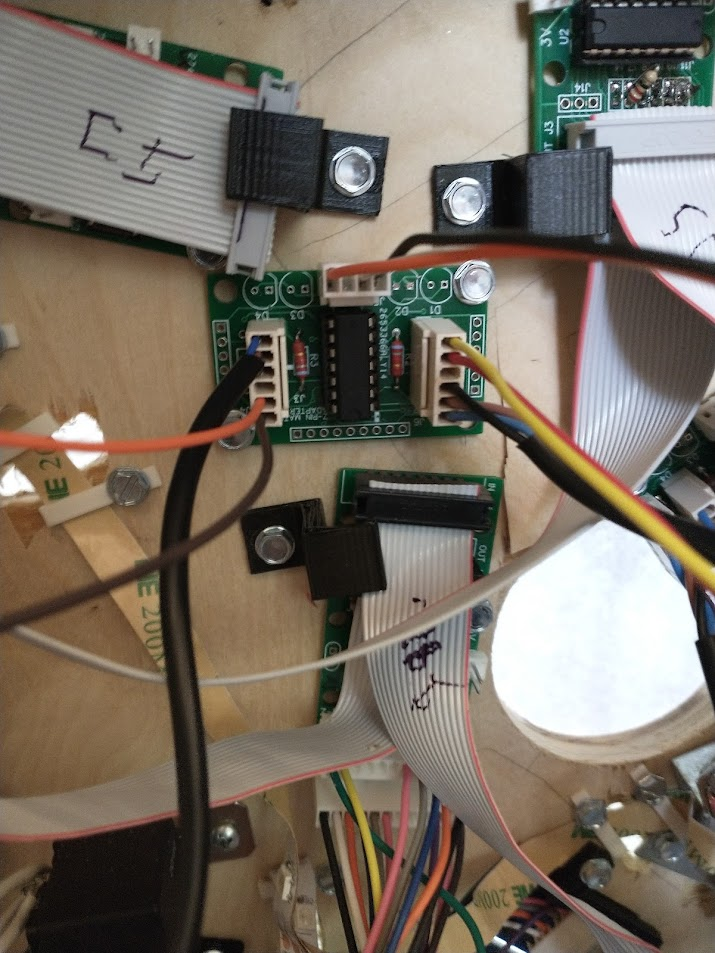

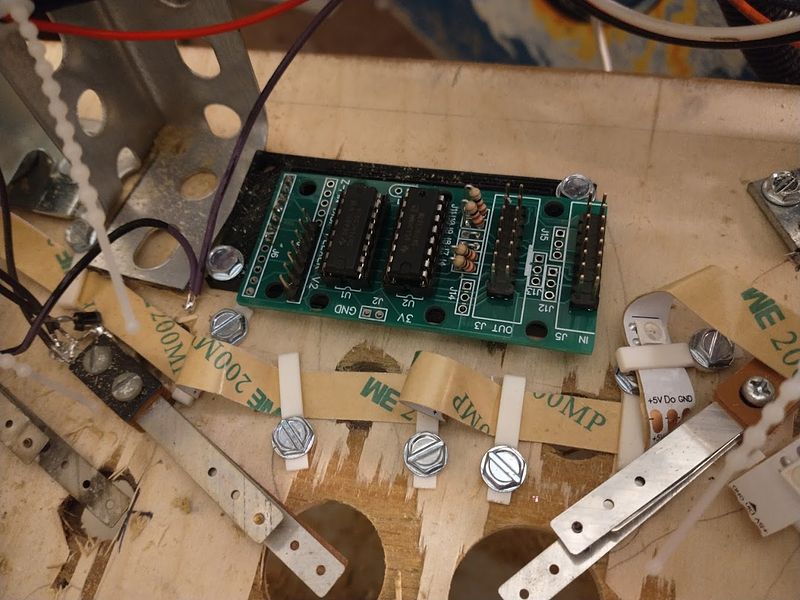

Leading up to the event, I had a few people by for last minute testing. This mostly went well, just a few bug reports, and mostly not game breaking, so I was able to resolve the important ones in time. With just 2 days to go however, suddenly the game completely died. No lights, no displays, and half the coils wouldn't fire. Eventually I found that the 5V fuse had blown, which would explain why the displays and lights died. I'm not sure what caused the fuse to blow, other than that I found one of the power connectors the for the displays had come off the board, so maybe it somehow brushed something? But it's not really a connector with exposed metal or anything. Anyway, the 5V also powers the mosfets for the solenoid drivers, so without that, some coils weren't getting enough power to fire. Sadly the way that they were getting power was that they were somehow powering themselves off the 3V from the CPU chip through their inputs, which managed to also smoke the CPU from the stress, so I basically had to rebuild both driver boards. Wish I'd noticed that I'd blown a fuse quicker, but not really sure what to do about that problem overall, so instead I just packed 2 spares of every chip used on the boards, in addition to a whole spare driver board, and crossed my fingers that'd be enough. Next game I'm going to try to move to a completely different architecture for driving my mosfets so hopefully this won't be an issue anyway.

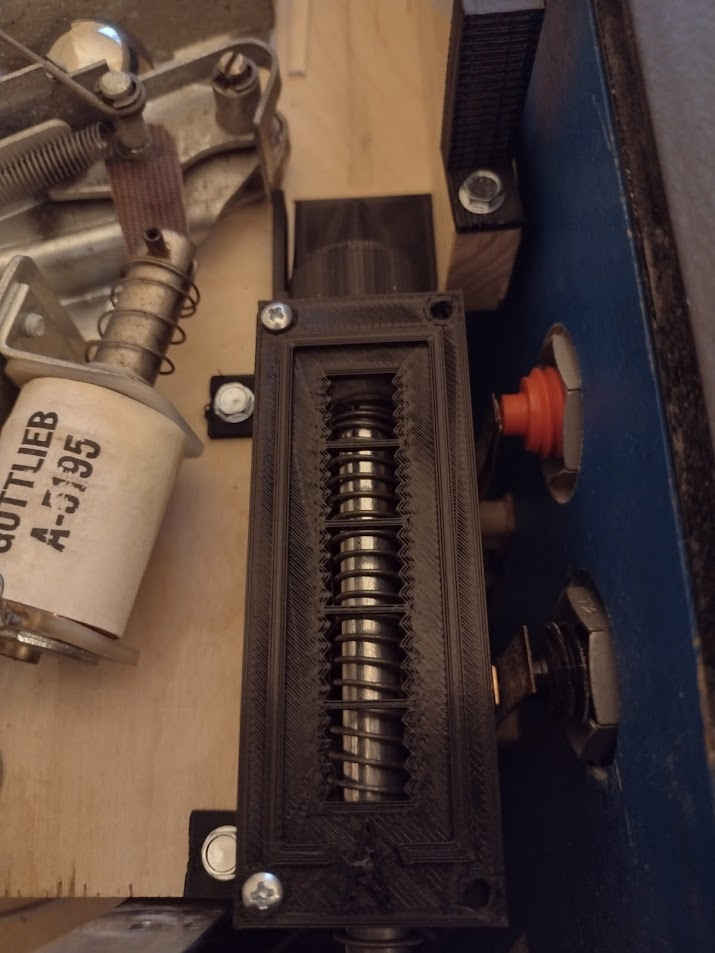

Besides from spare chips and driver boards, I also prepped 2 spare Raspberry Pis (although I've never had one of those fail) and 3D printed spares of every single part in the game, since I wasn't sure how the 3D parts would hold up. I've had some games at shows get 200+ plays in one day, and looking at my audits, I've played less than that many test games during the entire development cycle, so despite the game being mostly solid for the past few months I really was moving into new territory.

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

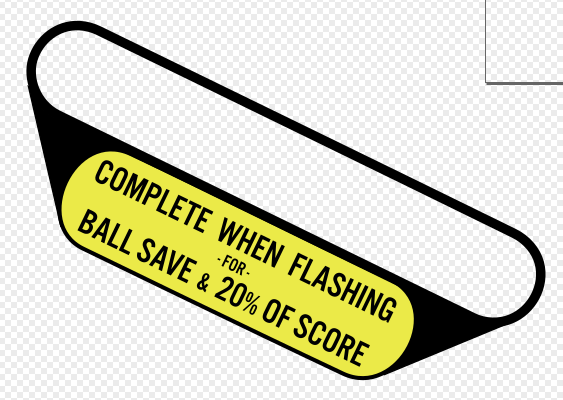

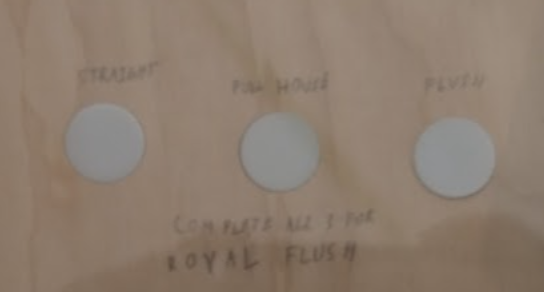

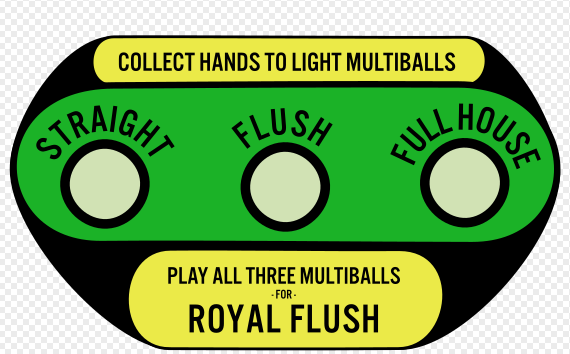

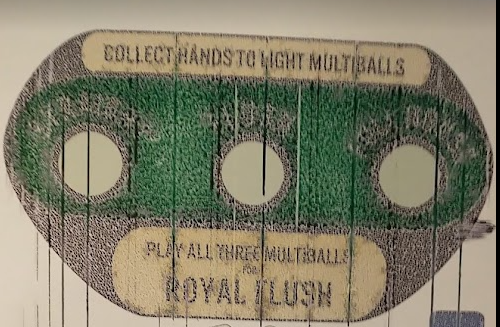

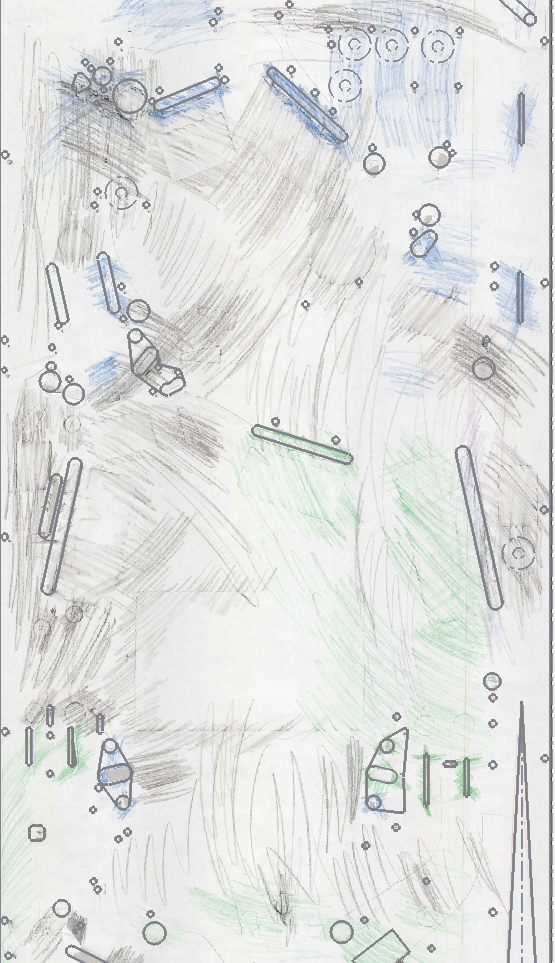

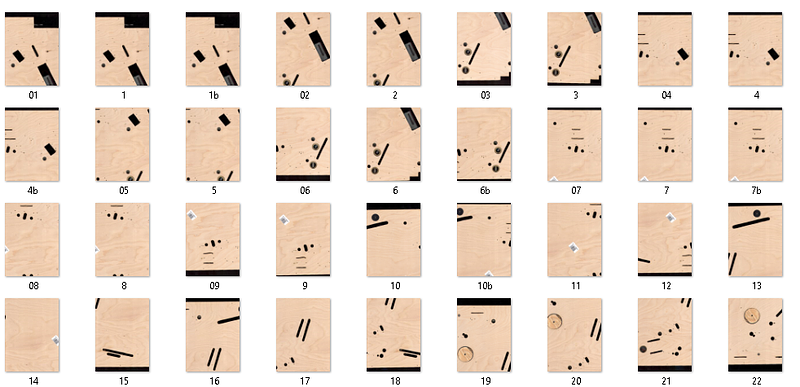

With a month and a half to go until pintastic, I was in a pretty good spot. The game was working fairly well, I had most of the features done and lots of issues worked out. I figured it'd just be finishing touches and bug fixes, and I was actually ahead of schedule! So then I got to thinking if there was anything else I could do in the leftover time. One thing that'd stood out from testing is that my pencil-drawn instructions and labels on the playfield weren't readable enough for people to notice. So I figured maybe I could draw up some simple text boxes on the computer for those. Using some gottlieb EMs as reference, I found out what font was usually used, and tried to copy some of their basic styling, and I drew some stuff up in inkscape

Those didn't look too bad! So I got a bit more adventurous with some of the other instructions I had.

But I needed to figure out how to get those onto my playfield... When I first started drawing these I'd figured I'd just get some "clear sticker paper" from Staples, but it turns out that... doesn't really exist. I ordered a few things like projector transparencies and decal paper, but those also didn't work out. Everything ended up transparent still, not opaque ink on a clear background, so they didn't look too good

After a bunch of searching, I figured that what I really wanted might be "window decals" which... aren't decals. They're just vinyl stickers. I ended up ordering some from signs.com since they were the only site I could find that had an exact scale option. I got both decals and window cling, thinking that the decals might rip up the wood but the cling would have a weaker adhesion, but it turned out the cling couldn't stick to the wood at all, and the decal's stickiness wasn't too bad

The decals went on fine though, and had pretty good 'blocking' so the woodgrain didn't show through, although some of the pencil was barely visible in some of the lighter colors so I had to go back and erase all that.

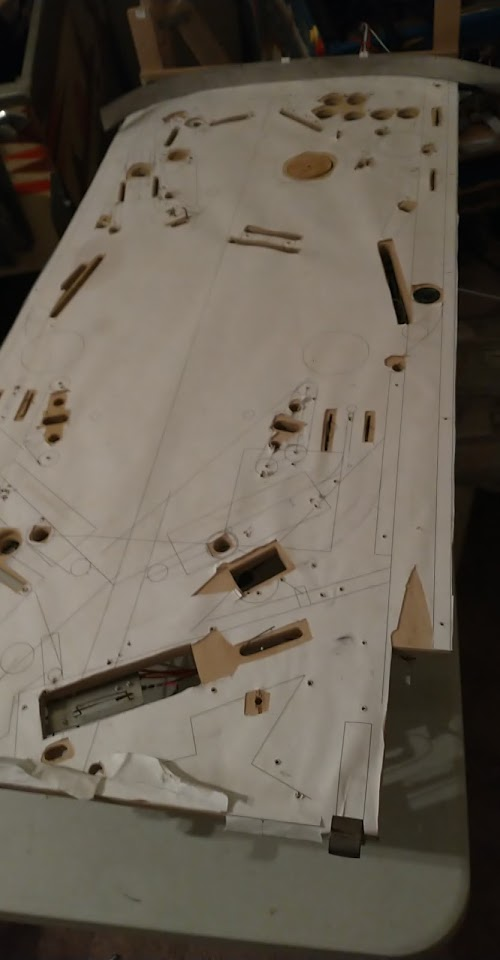

With that looking pretty good, I went ahead and spent a few evenings drawing even more instruction blurbs. And then got on a bit of a roll I did a few smaller things like keylines for all the inserts. And some graphics for the magna save, and around all the displays. And then I did all the major shots and lanes too because why not?  Now I had to tear down the whole playfield to install all these.... Most of the small ones weren't too bad. The larger ones (some are up to 20 inches long) got a bit more complicated though, especially the ones that needed to line up with lots of different playfield features. I'd never really done decal work before so I had to figure it out a lot as I went, but luckily they were forgiving enough that I could peel them off a few times to get them right before they started to loose their strength, and were slightly stretchy too so I could bend them a bit to line things up. That stickiness also became an issue though when I tried to put some over the displays, and the stickers started to sag down over the hole.

Now I had to tear down the whole playfield to install all these.... Most of the small ones weren't too bad. The larger ones (some are up to 20 inches long) got a bit more complicated though, especially the ones that needed to line up with lots of different playfield features. I'd never really done decal work before so I had to figure it out a lot as I went, but luckily they were forgiving enough that I could peel them off a few times to get them right before they started to loose their strength, and were slightly stretchy too so I could bend them a bit to line things up. That stickiness also became an issue though when I tried to put some over the displays, and the stickers started to sag down over the hole.

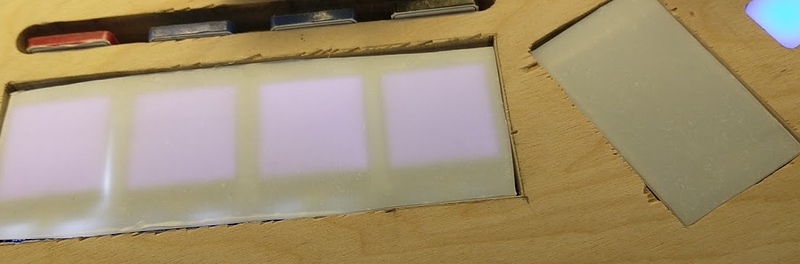

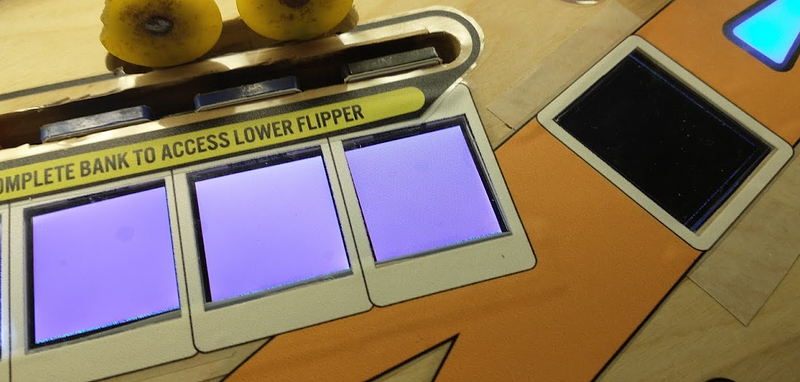

I ended up having to cut out some spare plastic sheets to cover the displays with in order to support the stickers. Then a new problem was revealed, as the backlights of all the displays had some light bleed that was showing through the stickers and didn't look too good, so I had to mask off portions of the plastic with electrical tape

There was also a few issues with the center, clear portions of the stickers not adhering to the plastic perfectly, creating bubbles or trapping little bits of dust, so I also had to manually trim out the center portions with an exacto knife in some cases

The biggest challenge, however, was also the biggest sticker. Somehow this massive part, which I couldn't find some way to split up, didn't come out one-to-one scale, despite being in the same file as everything else

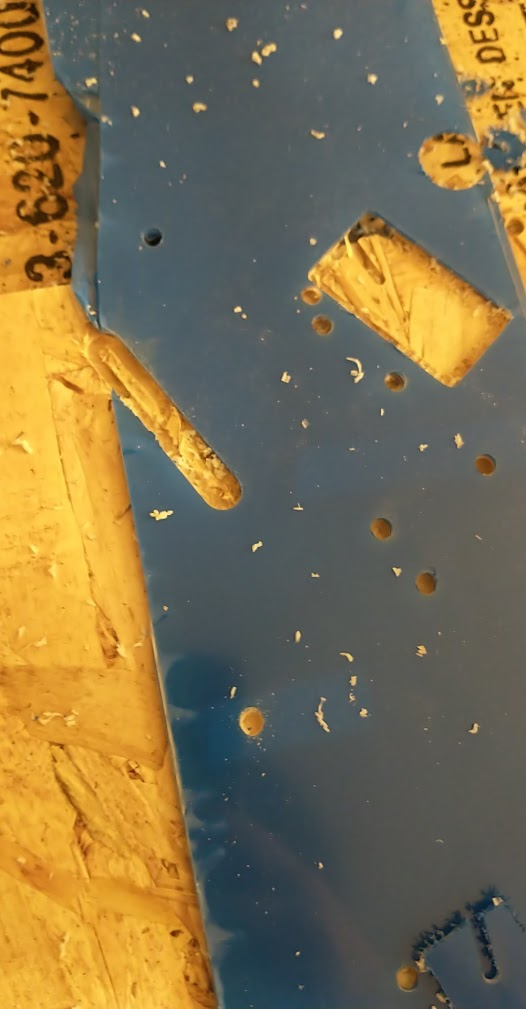

The piece should be 23x8", but instead it was 24x8.5". A small enough different that I didn't notice it during proofing, or when I got the sheet, until I cut it out and actually put it on the playfield. And since it was the biggest, most complicated piece, I saved it for last too ![]() At this point, there was under two weeks until pintastic. It'd take at least 2-4 days for another decal to be made, plus 3-5 days to ship, and I still needed to reassemble everything and do a bunch of final testing, so I didn't have time to wait for a replacement. At first I figured I'd just leave it off, but that one decal was basically a whole quarter of the playfield, so it was really obvious. In a flash of 1am, "nothing left to lose" decision making, I decided to just cut the whole decal up by hand and rearrange it to fit.

At this point, there was under two weeks until pintastic. It'd take at least 2-4 days for another decal to be made, plus 3-5 days to ship, and I still needed to reassemble everything and do a bunch of final testing, so I didn't have time to wait for a replacement. At first I figured I'd just leave it off, but that one decal was basically a whole quarter of the playfield, so it was really obvious. In a flash of 1am, "nothing left to lose" decision making, I decided to just cut the whole decal up by hand and rearrange it to fit.

This went... much better than expected. In the end the one decal became 16 separate pieces, which I then cut apart, layered, and stuck back together so that all the keylines still matched up. Close enough! With the plastic protector over it you barely even notice. It'll be fun showing it to people and seeing if anyone asks about it. I've ordered the correct decal, along with a few other corrections too, so the next time I do need to tear the playfield down and get the protector off, I can replace it.

Since I was already ordering from a printing place, I also got some reverse-printed decals for my plastics

They weren't quite as vibrant as I'd hoped, but still much better than my inkjet-printed ones are. Plus they're adhesive, so the paper doesn't sag under the plastic. Before:

After:

Aaaand... done! I wish I'd been able to come up with a few more bits of actual art besides the one hand of cards between the flippers, but I wasn't able to really find anything else that fit with the theme and art style so far.

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

Falling behind on updating this thread as the final crunch intensifies ![]()

Lots of little things going on...

I've been trying to track down all the 3D models I used for the build to print up spares. In a few cases I can't actually find the original file anywhere! Not sure what to do about that, as I thought I'd been tracking everything fairly well, with consistent naming and versioning. A few small things I had to re-model, or I'm stuck with just the generated g-code and I can't really edit it anymore.

With some plastics with art on them, I figured the mismatched drop targets stood out a bit, so I made some quick stickers for them

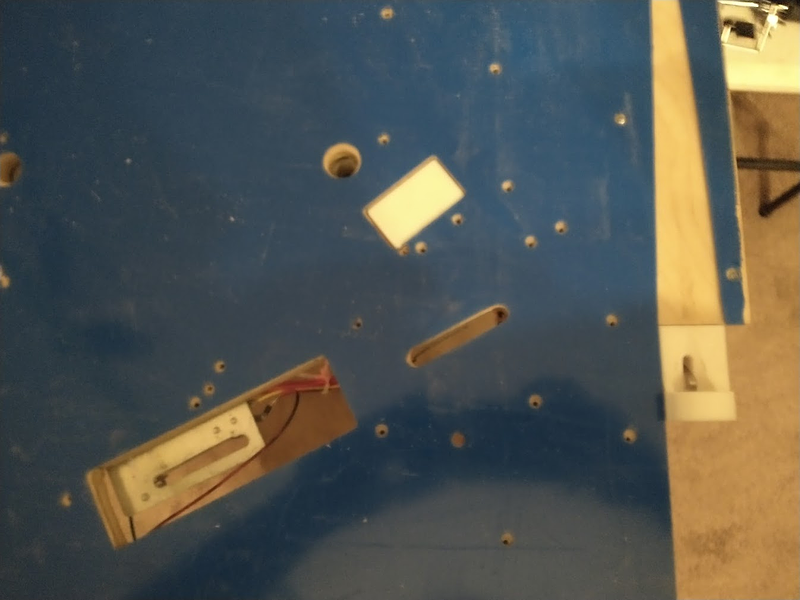

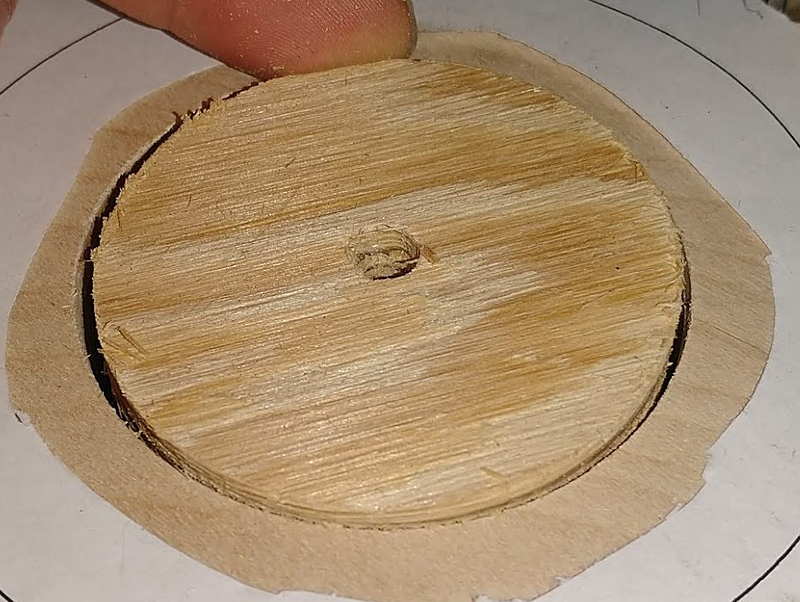

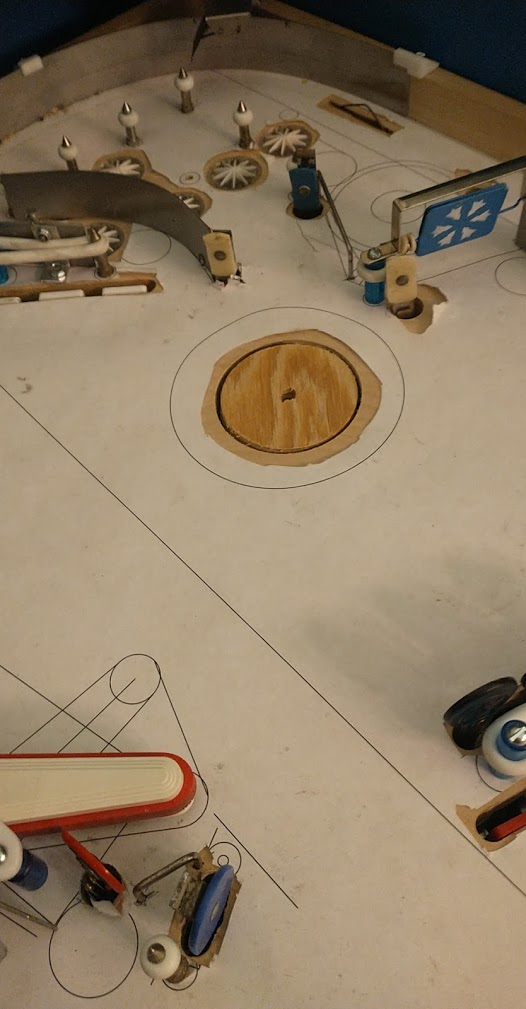

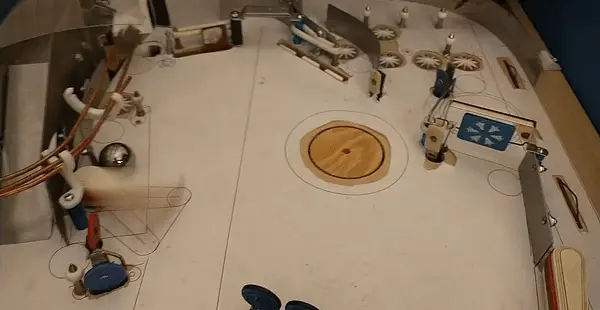

In a bunch of places I had holes in the playfield where I'd installed features and then removed them later, so I'd just taped some paper over them, but that was also a bit ugly.

Luckily, I had some scans of the playfield from before I'd cut many of the holes, so I printed out stickers of the wood grain and covered them up ![]()

As more playtesting got done, I started having issues with a few connectors falling out of stuff. Usually I'd used connectors with latches/ramps to prevent that, but in some cases I couldn't. So I 3D printed some little braces to hold stuff in

I did a bunch of little quality of life things in the code. Hold start to end game. Tweaks to a lot of switches. More instructional text. A lot more feedback as stuff is happening, like these little blinks when you hit something to help you know it wasn't a near miss or something

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

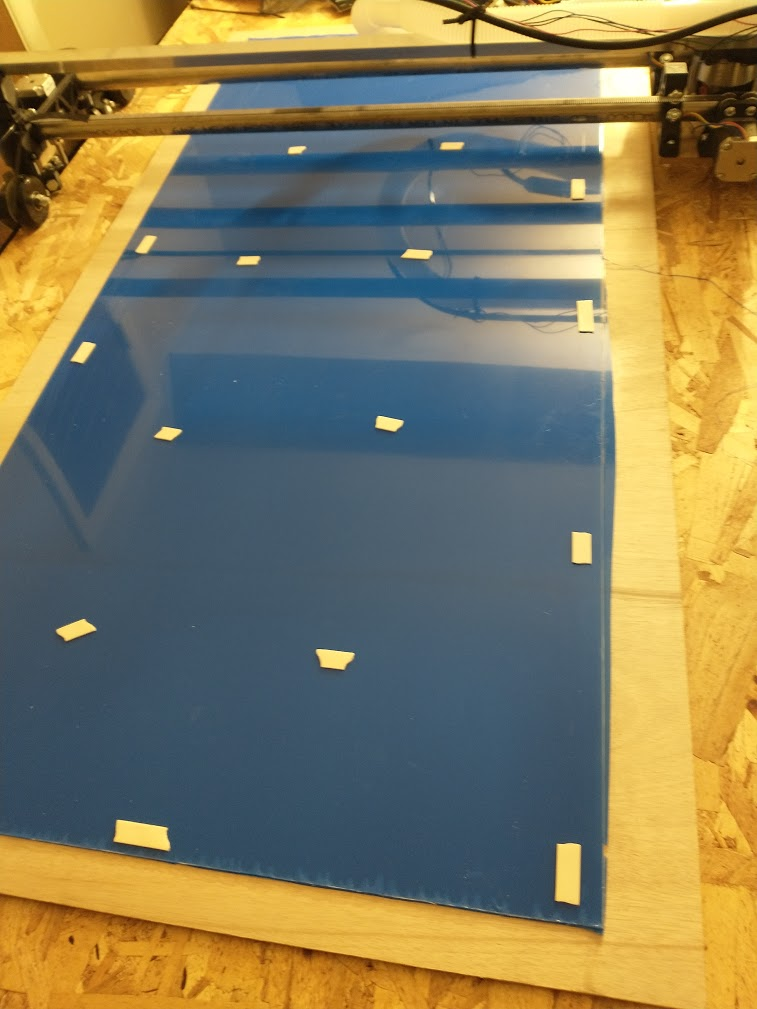

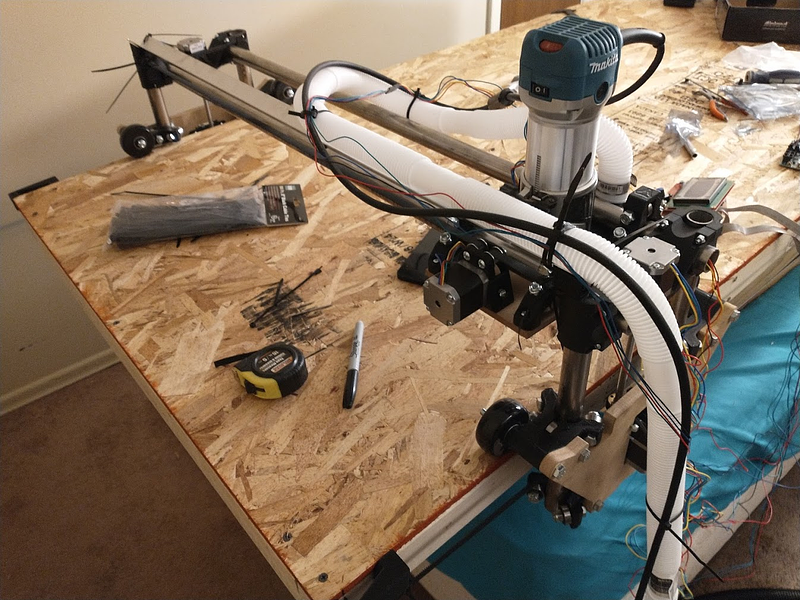

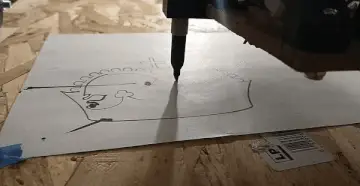

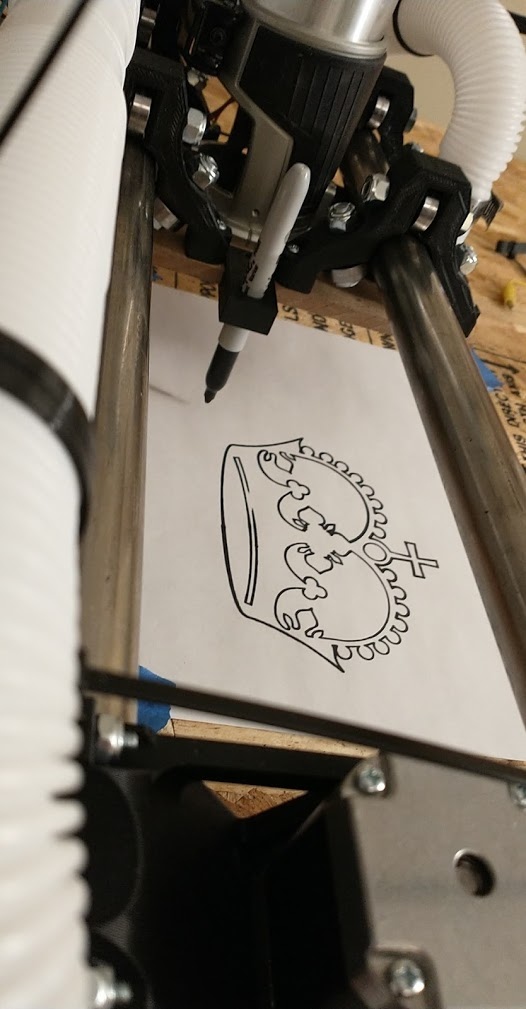

While out shopping, I saw a Cri-Cut for sale, and thought "that would be handy to cut some stencils!". But then I thought: "wait, why do I need stencils? what if I just cut the art out of vinyl directly?" So I grabbed a roll of 'removable' adhesive vinyl from the supply area and tried it out on the cab. It looked fine, and seemed to peel back off without damaging the webbing, so that sounded good. Except I didn't want to drop $300 on a cricut. So I bought a $10 'drag knife' vinyl cutter attachment and hooked it up to my CNC router instead ![]()

Took a few tries to get everything adjusted properly and figure out a workflow, but once I worked out the kinks it worked quite well.

Hand positioning and applying them to the cabinet also took some trial and error, but no major issues

As always, learning that even a tiny bit of art goes a long way. I'm not going to win any awards here but it's turned out pretty solid despite my zero art skills

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

Usually people spray cabs to paint them, but I don't really have the space to do that, so I opted to try using a roller. I set up a tarp in the middle of my game room, put the cab down on it, and applied about 6 coats of paint, sanding between each few. The texture from the rollers sanded off pretty easily in most places, but I still had a lot of places where the sanding wasn't doing much. I think this was more to do with the wood than the painting though. If I was doing a proper restore I'd have used more filler and stuff to get everything flatter so that the sanding would hit evenly. Also I'd have a power sander instead of just a sanding block. Whoops. I'm not aiming for perfection though, as long as nothing doesn't look like an obvious mistake, I'm okay with it.

After my quart of paint ran out, I decided to try to do some webbing like many EMs have. Both because it looks cool, and because it'll probably help hide more of the imperfections in the base coat and wood. I saw a few people recommending Montana 'marble effect' spray paint with good results, so I gave it a shot here. Originally I was going to bring the cab out in my yard to spray it, but because of the weird way that it works, even a tiny bit of wind messes it up, so I had to do the spraying in doors :/ Luckily with a bit of 'masking' around the sides I was able to do it without any mishaps.

With my black stern siderails, black painted lockdown bar, and some black legs and shooter rod housing I picked up, the white really pops; I'm pretty satisfied with how it turned out overall

I still need to figure out the stencils for the side art to go on top of this, so that'll be a task for another day. I figure I'll need to mask those anyway, so it doesn't hurt to have the rest of the game reassembled when that happens, and in the mean time this looks leagues better than the peeling whirlwind art that was on it before

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

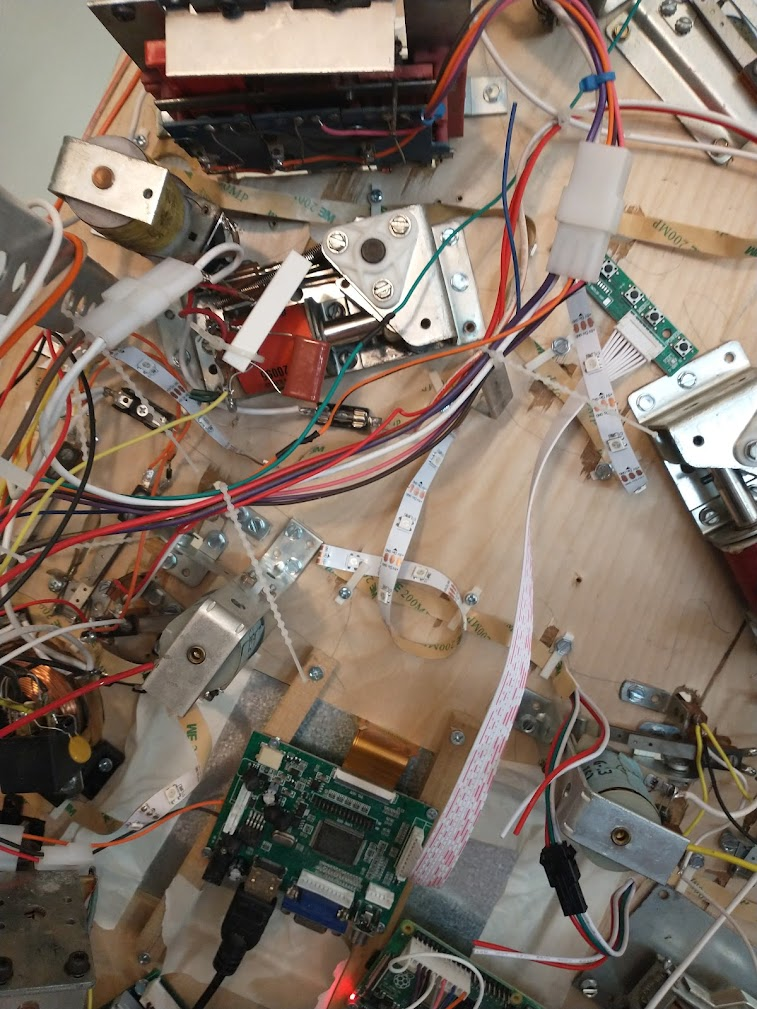

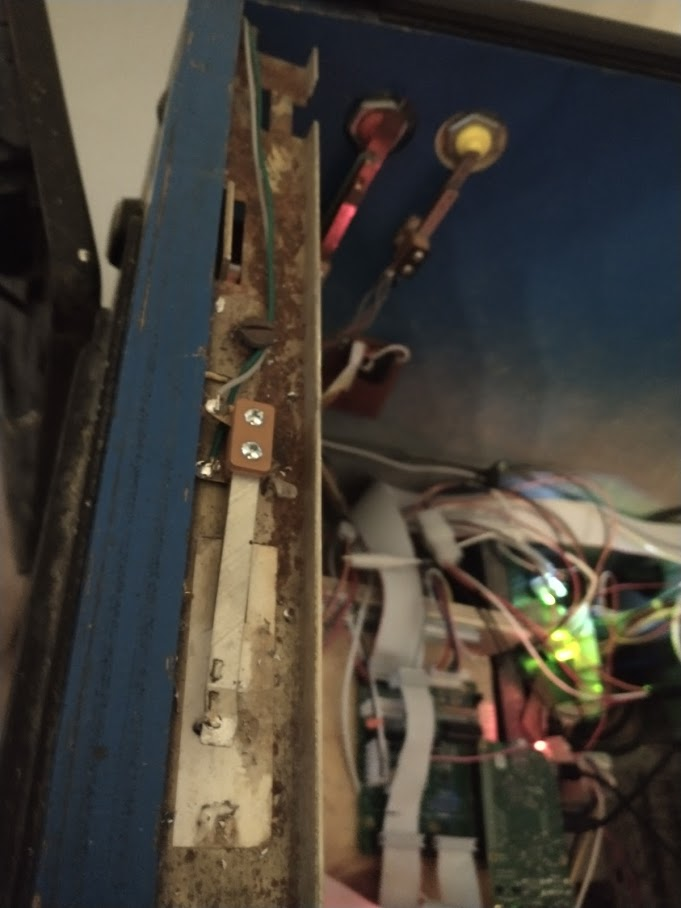

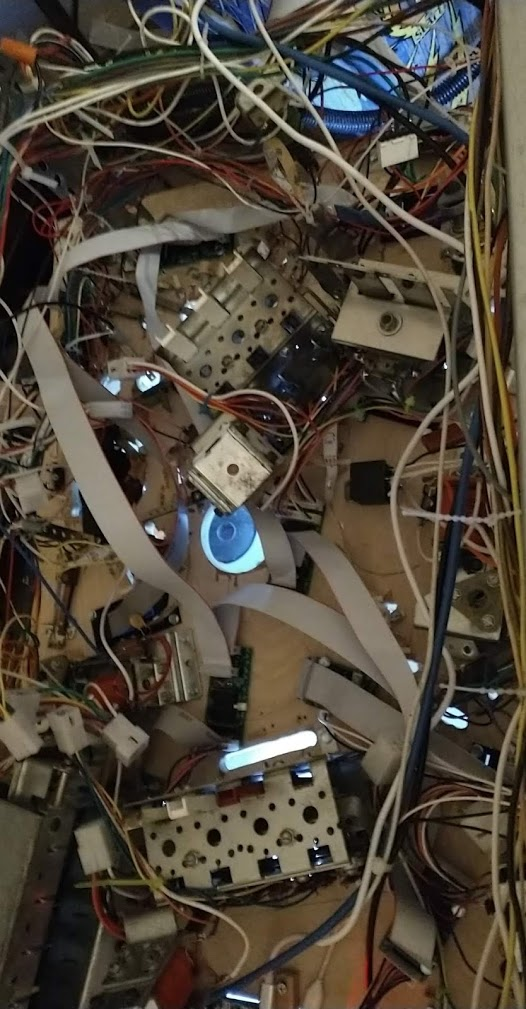

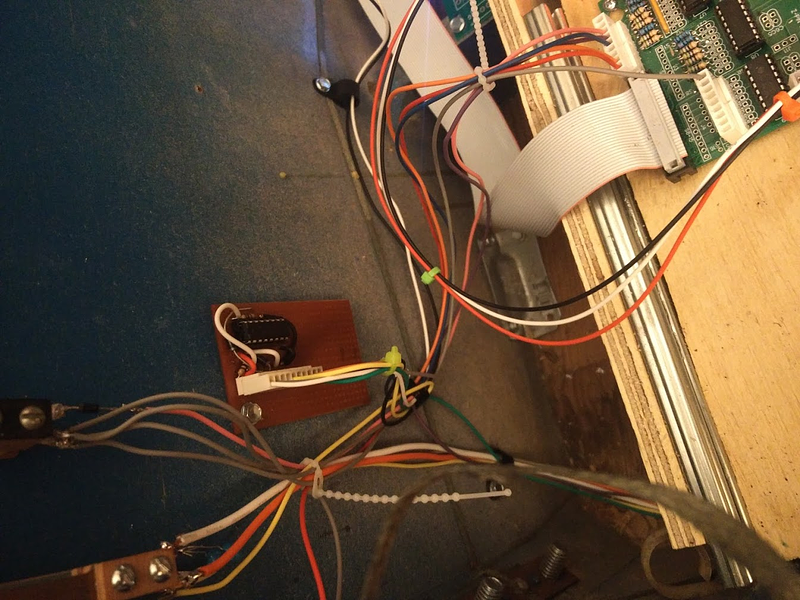

Since things were looking pretty good as far as my pintastic target, I decided to make a questionable decision and try to get some cabinet art in too. First, I took out the playfield and neatened up the cabinet wiring some more.

It still doesn't really look that neat, but everything is actually routed around and attached down, so I'm not really sure what more can be done on some fronts. Part of the mess is probably just the weird way everything is arranged and packed in, plus a lot of premade components that weren't meant to go together like this, like all the extra wiring on the transformer and power supply, or the USB, HDMI, and ethernet cables that I can't really chop down to their exact lengths easily.

The playfield wiring also isn't as neat as I'd hoped. When I started this project my plan was to have just two connectors going from the cabinet to the playfield: one for power and one for data. The driver boards were all going to be mounted to the playfield like on a Spike game. Instead I have two big black hoses full of ~30 separate solenoid power lines snaking all the way to the driver boards in the cab. My single power connector became two since I separated out the low and high voltages. And instead of a single 'data' connector, I now have an ethernet cable, an hdmi cable, a switch matrix cable, and a led cable. Those last two probably could have been combined, but there isn't much I can do about the others since they're standardized. All of that winds up as a lot of connectors (14 at last count) that I need to unplug and remove from their routing to remove the playfield ![]()

With the playfield out I was able to take the cab down to get it sanded. That also meant I finally got to clean it out a bit. A lot of random stuff accumulates at the bottom of a pinball cab when you're building a game in it!

Now, time to sand it down:

Next stop, Home Depot to buy some paint. I've never done a cab 'restore' before, so this should be interesting

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

I scanned the plastics I had in with my printer and started mocking up some simple art using a CC vector playing card art pack I found online, then just printed them out on paper for a test

The paper didn't really turn out that great. Colors were very muted compared to how they look on screen, and without being glued to the plastics it still sags a bit and looks a bit messy, but they still really help pull the playfield together. I'd like to try to make up a few more paper bits to put on the playfield itself, at least where my hand written rules currently are, but that'll have to wait until I take the plastic off again. I've basically given up on ever having full playfield art for this, but I think a splash of color here and there should be more than enough. Once I've got the rest of the plastics made/mounted and drawn up I'll get them printed professionally somewhere for some better colors.

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

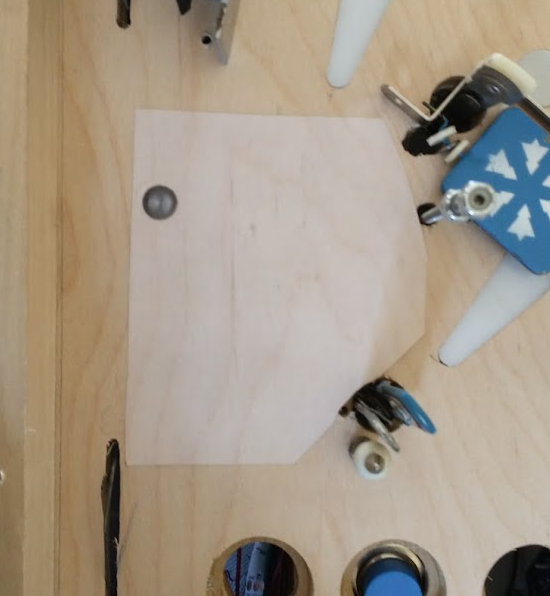

One thing that didn't cause any issues during testing, much to my surprise, was the lack of plastics. I thought for sure some airball would end up sitting on top of the slings, or manage to fall into the apron area since there's no apron, but that didn't happen once. Nevertheless, it needed to get done. I started by just sticking some index cards on the posts, and hand cutting them roughly to fit the shape

Once I had a few forms ready to test, I grabbed some scrap material from my last playfield cut to practice cutting with scissors and see how clean I could make them. Before I could actually get cutting though, I realized that one of the scraps I'd grabbed looks a lot like my slingshot.... Because it was! Not sure why I didn't think of it sooner, but obviously if you cut out a playfield protector, the left over 'negative' space will be sized to the unplayable areas, which is where the plastics need to go anyway.

So I drilled a few holes for the posts, peeled off the protective layer, and then drew a border with dry erase marker so they'd show up, and:

Not bad! The left sling went the same way, but I needed to manually cut out a bit to fit the gate in Most other plastics weren't so clear-cut, but I was able to eyeball it and get them to fit without major issues

Most other plastics weren't so clear-cut, but I was able to eyeball it and get them to fit without major issues

Even the apron was almost ready-made once I chopped it out of the scrap border plastic, although it's not perfect as I had to leave a hole for the handle.

I don't have any 'front' wall for the apron yet either, so I guess technically an airball could still get up there and end up stuck between the apron and the glass, but that's still much better than it falling in and potentially hitting the mechs or something

One thing I hadn't really counted on was the actual mounting for the plastics. For the slings it wasn't too complicated as I just needed to swap the phillips screws for standard pinball ones with a 6-32 thread on top, but many places were made mostly out of mini-posts, which I used since they have the smallest diameter, allowing me to fit more stuff into some tight spaces. They worked great for that, but since they have a pointed top I can't use them to mount plastics, so I'll need to swap some of those out. Trouble is, no one makes a similar post with a wood screw on the bottom and a threaded top, so I may need to dig in deeper than I was hoping and start installing some t-nuts and machine screws. I didn't really plan the playfield with that in mind beyond a normal "well I can swap to machine screws later if the wood strips out", so a lot of those posts are above mechs and may need to have the t-nuts recessed or other annoying things.

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

Had a small get together at my place last weekend, and had the game set up and playable during that time, with a camera on it. I recorded about 12 hours of video, although some of that time it probably wasn't being played... Twice I had the solder break on the flipper wiring to the resistors. I'll need to think of a better way to mount those. Currently they're just hanging awkwardly from the coils from when I first attached them for testing, which obviously is bad. Once the flippers just died randomly, and came back next ball. Not sure if that was a tilt or something correct that the player didn't notice, or if something malfunctioned. Will have to track it down in the recording and see. One time the ramp switch didn't register, which has been a recurring issue. I've got it tweaked 'just right' so it's 99% good, but I need to figure out a better solution eventually. This wouldn't be too big of an issue, except the lock post in the ramp won't let the ball back down, since it doesn't know it's there. I had two other stuck balls, both times they were caught by the shooter lane diverter, pressed against the back of the drop target next to it. Both of these issues will at least be alleviated by a ball search, which I'd never gotten around to coding before. So the next day I added one in. Not too complicated... I shouldn't have put that off so long. Besides from that I had no reported issues, although I'm sure a lot of that was people just not knowing how the game is supposed to work.

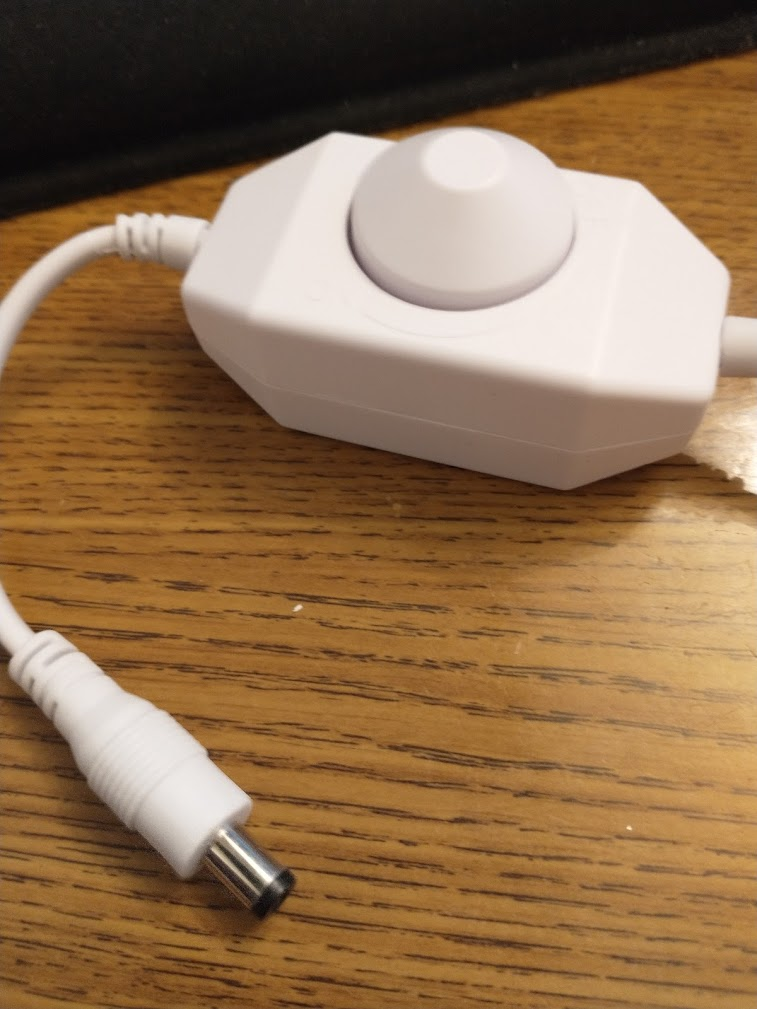

Another thing that's been on the todo list for a long time: adjustable GI. When I originally got the led strips, I got some super bright 12V ones since I was worried about how well they'd work. Although the center of the playfield is still a bit dark if you turn off all the other lights in the room, overall it's more playable than some games, but in a lit room they're a bit much. Usually more light would always be better, but they tend to make it harder to see some of the mini displays, especially the ones along the edges. I considered trying to hook them up to a solenoid driver, and manually PWM them to get them to dim, and also give me manual control of them in the code (although I don't really know when I'd use that), but that sounded like it could be a bit of a pain (and who knows if my mosfets can handle that much current), so instead I ordered a cheap 12V LED dimmer off eBay.

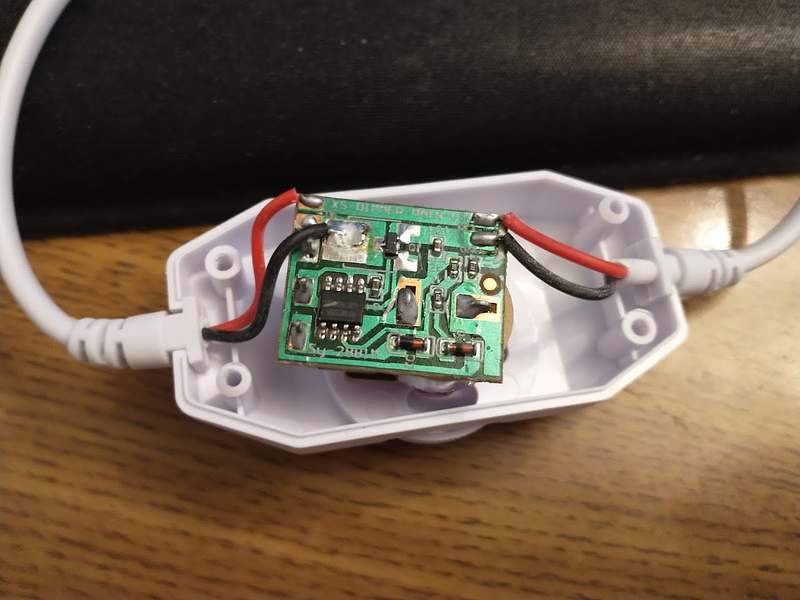

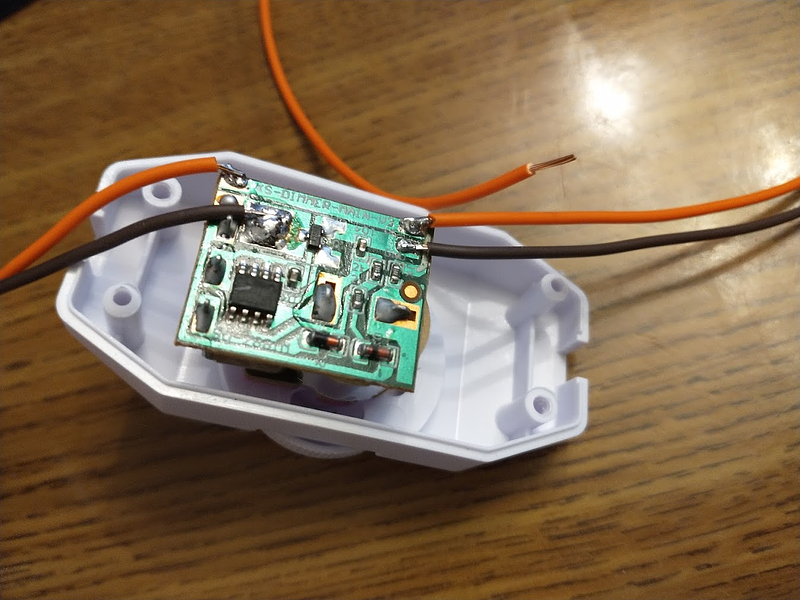

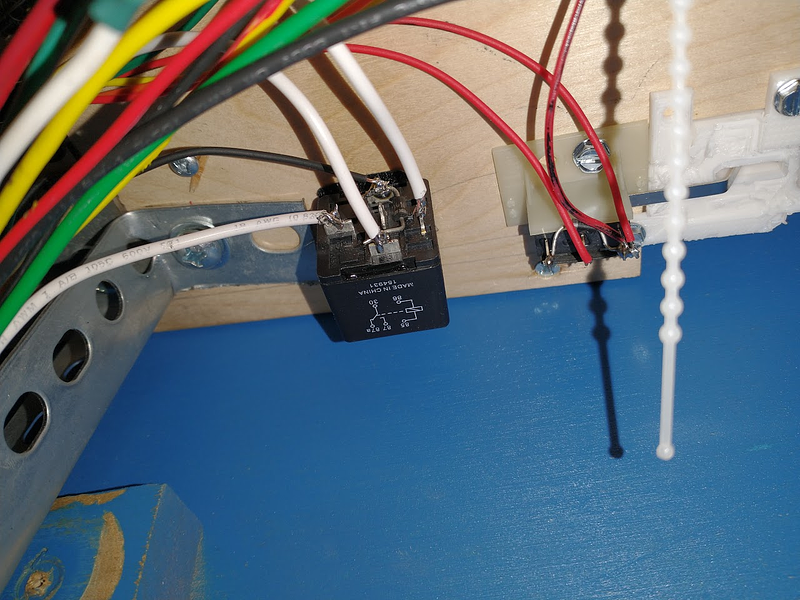

It had these annoying bullet plugs that a lot of electronics have, but I've never had a good way to deal with. I was about to go about my usual process of cutting off the plugs, then buzzing out the wires to figure out which is which, and heat shrinking some new wires onto it, when I had a light-bulb moment: what if I just opened it up? Sure enough, two phillips screws on the back were all that was needed to open the case and see four nicely color coded wires soldered to spots on the board

A little bit of soldering, and I now had my own wiring and connectors attached ![]()

The dimmer works great, and I now have fine tuned control of the brightness of the GI (and can even turn it off if needed). Still need to find some way to mount this in the cab, but that'll be an issue for later on. At some point before the weather gets too cold I'd like to take the game apart, clean the inside of the cab and put in some final cable management for everything, then sand and stencil the cab with some playing cards.

While I was in the game I also took the opportunity to wire up a few more inserts: 3 in the center of the playfield to show your progress towards a potential wizard mode, and two more in the mini playfield. I stopped using the star rollovers I had installed there to sense the ball a while ago when I made the new diverter, and luckily I was able to find some white inserts that were the same diameter as the star rollovers to replace them with, so now I finally removed the switches and wiring underneath too.

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

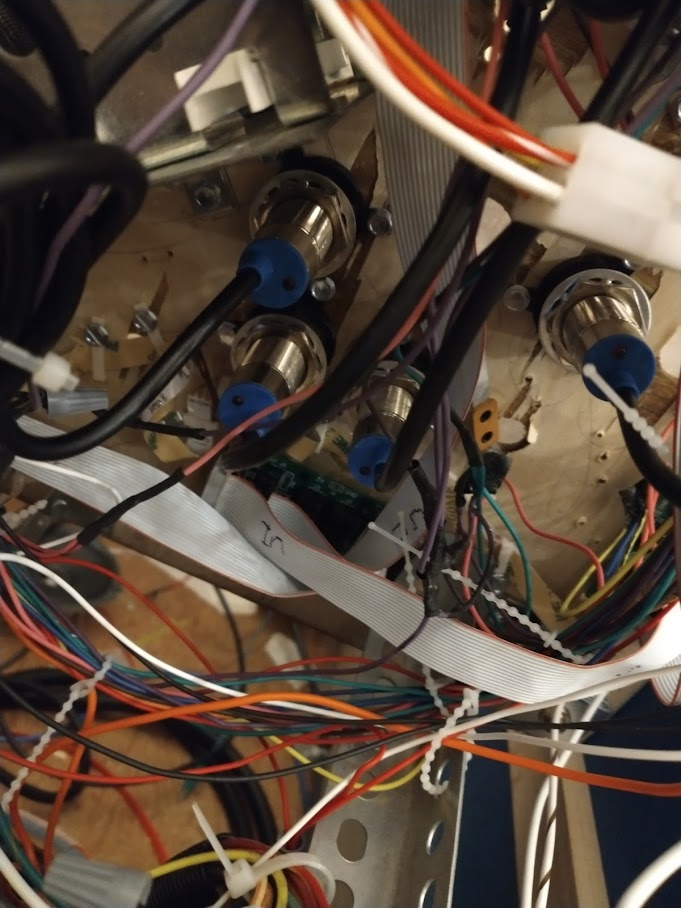

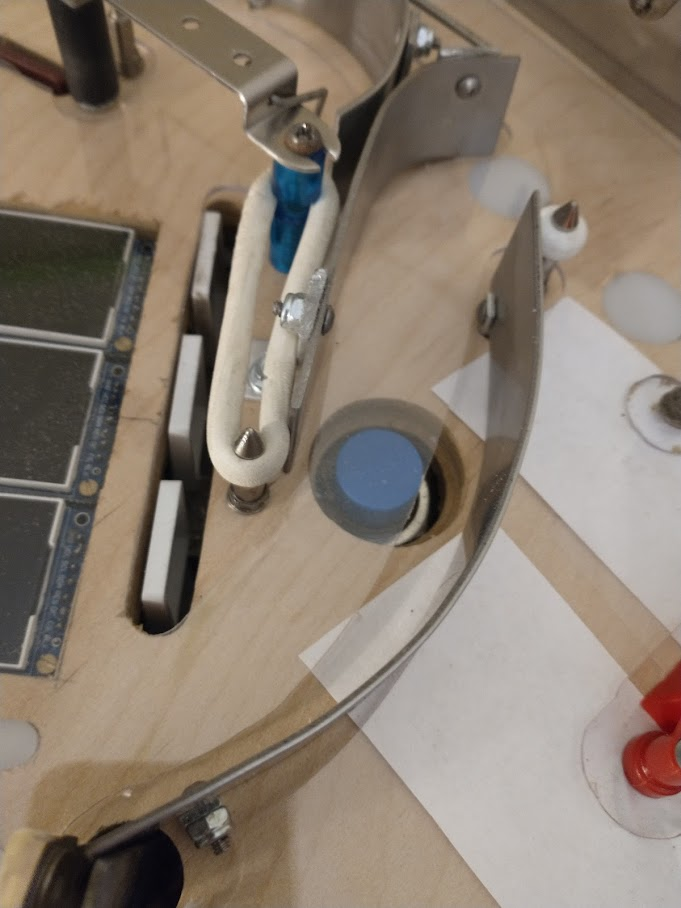

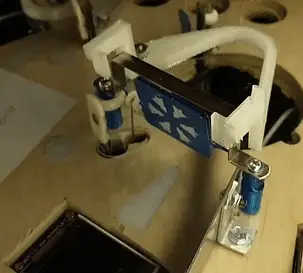

One of the issues I kept running into with the plastic covers was the rollover buttons. My 'free floating' 3d printed ones had ended up working pretty well, but sometimes they'd cause hangups with slow moving balls if the button was also stuck at an angle. In my quest to solve all potential ball trap points, something needed to change. Then someone on the slack channel mentioned these inductive proximity sensors:

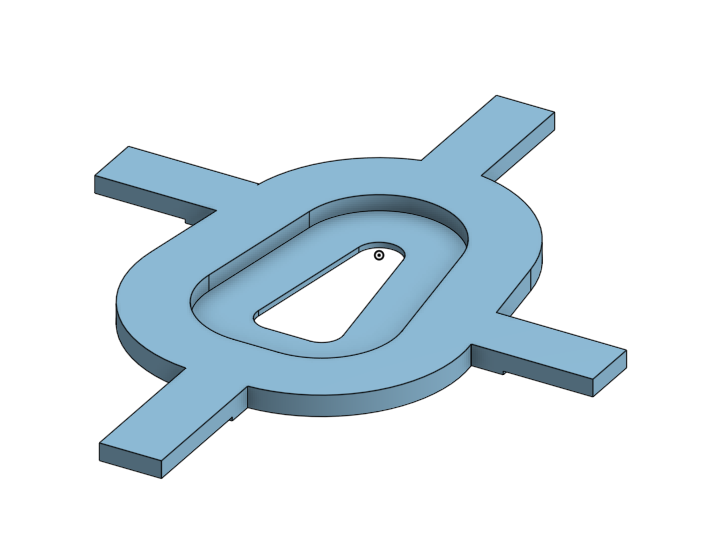

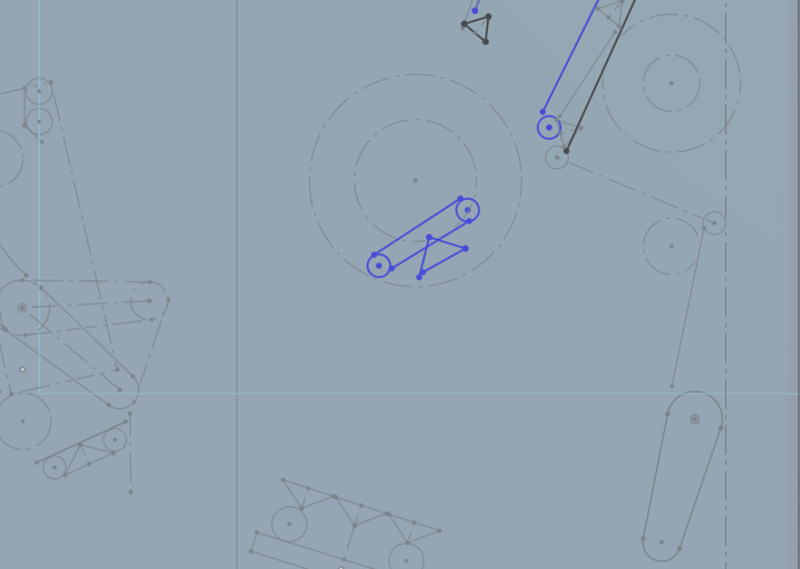

Given their side and range, plus the fact that I don't have a wooden playfield in the way, these seemed like a good way to avoid having to deal with sticking the rollovers through the playfield at all. I ordered a few and my initial tests seemed positive. They were easy enough to power from my 12V supply, and just acted like a normal switch once I added a pulldown resistor. The one issue is that I'm using a switch matrix, so I needed some way to interface these 'constant' switches in. I designed yet another little board to go under my playfield which would basically just hook 4 proximity switches into the matrix

I designed some simple 3D printed mounts, and replaced all my rollover buttons

This wasn't quite as well thought out as I'd like, and I had issues fitting them into a few places. I was able to get around that by using some 12mm sensors in a few positions instead of the better range 18mm ones, but the detection of the 12s isn't quite as wide as a star rollover would be. The biggest problem is the rollover in the shooter lane. The 5 bank of drops doesn't leave much room between the rollover and the wall, and the area is just wide enough that the ball can sometimes worm its way past without triggering it.  I may have to look into cutting my support rails a bit to make room if this doesn't work out, but I'll see how noticeable it is first. Since I eyeballed the entire cabinet without any planning I've been leaving about 5/8" room on both edges of the bottom of the playfield through the entire length so that nothing could possibly obstruct the support rails, but it could be that this area is far enough forwards that I don't need to worry about it.

I may have to look into cutting my support rails a bit to make room if this doesn't work out, but I'll see how noticeable it is first. Since I eyeballed the entire cabinet without any planning I've been leaving about 5/8" room on both edges of the bottom of the playfield through the entire length so that nothing could possibly obstruct the support rails, but it could be that this area is far enough forwards that I don't need to worry about it.

Overall these proximity sensors are really cool, and if I'd known about them before I started building my whole playfield might be completely different. I could see myself avoiding rollover lane switches entirely, and maybe some of my hanging gate switches on shots too. The one downside is how tall they are. Compared to the very compact sensors I've seen on the Alien pinball machine, they really obstruct stuff under the playfield, and there's a lot of stuff like mounting them sideways in ball guides and stuff that you could never do. Once I get another shipment of spares in I'm going to chop one open and see if all that size is really needed, or if it's just a big empty cylinder to fit some standard industrial form factor or something...

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

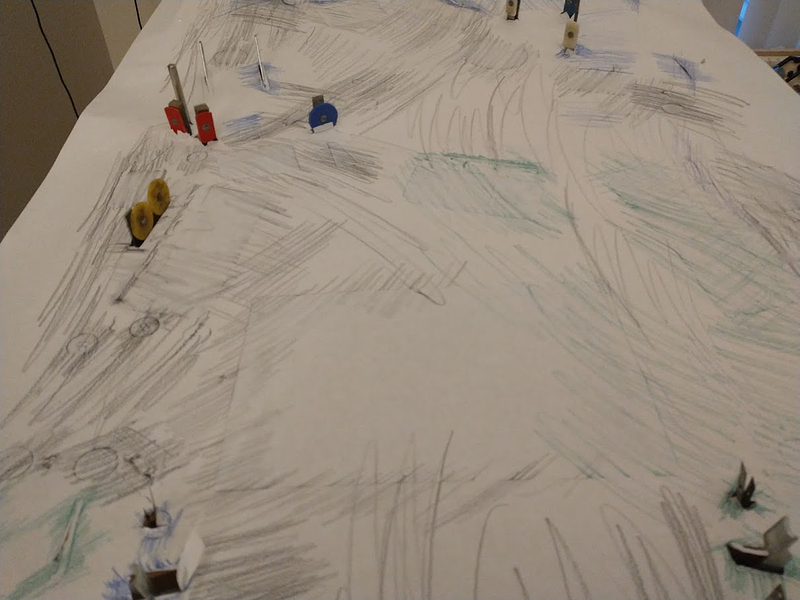

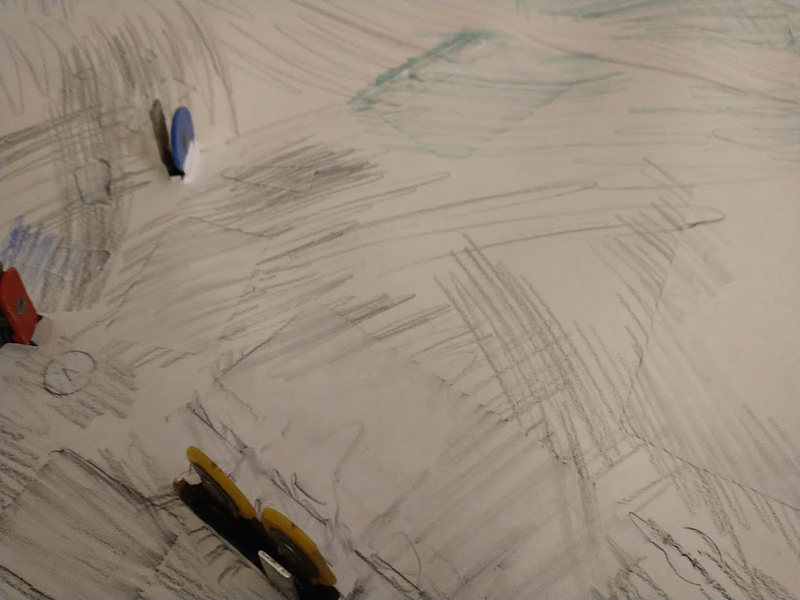

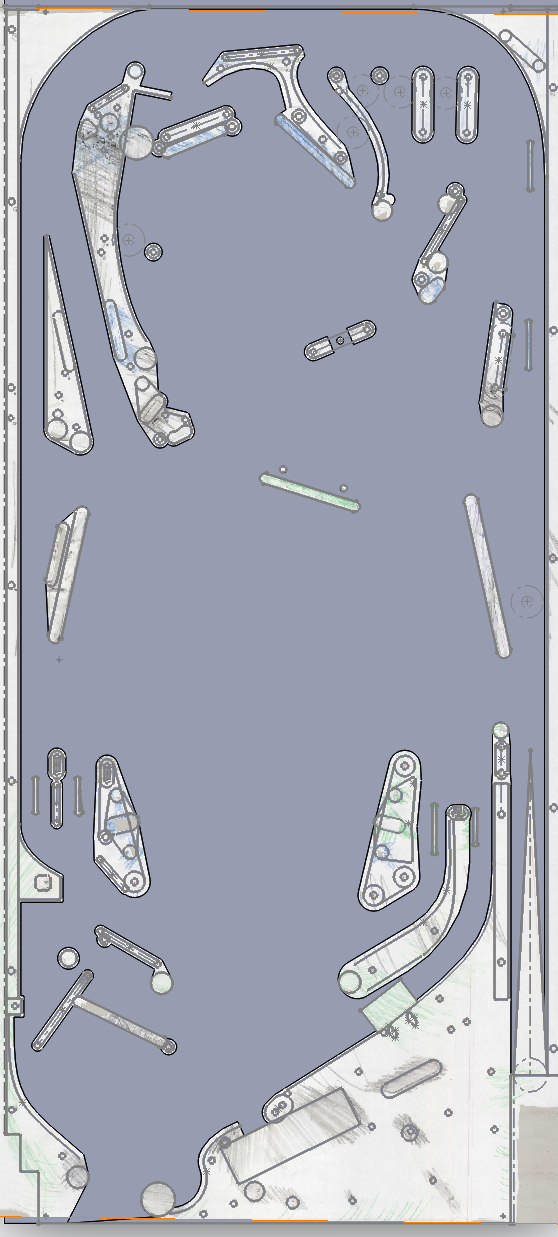

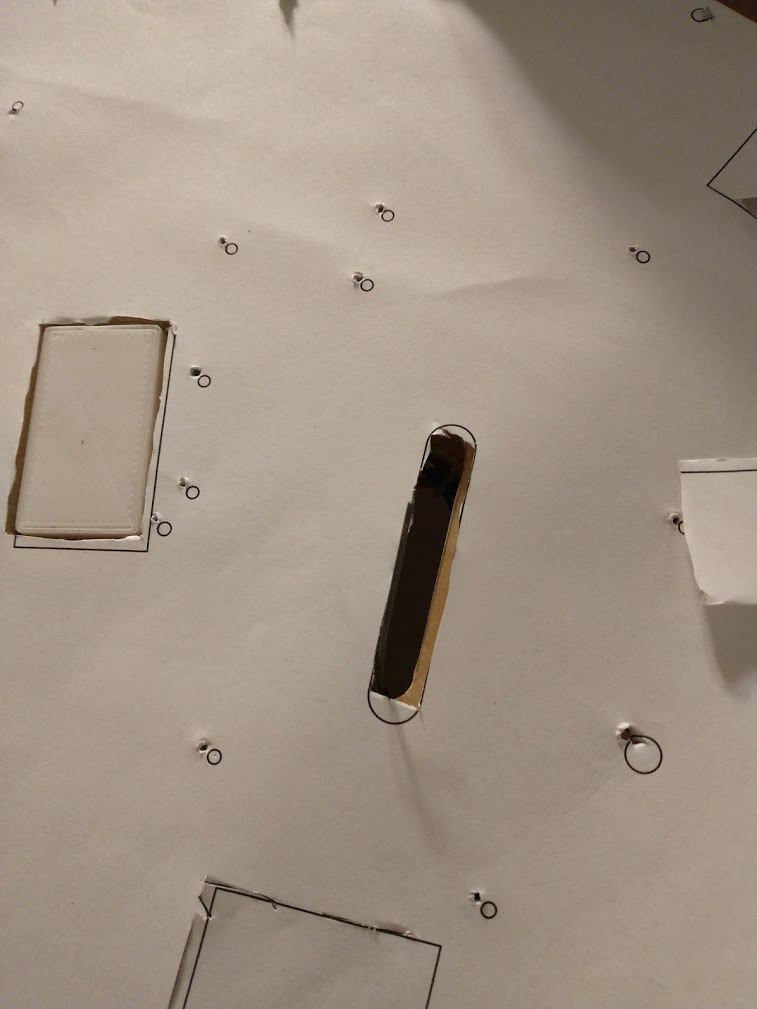

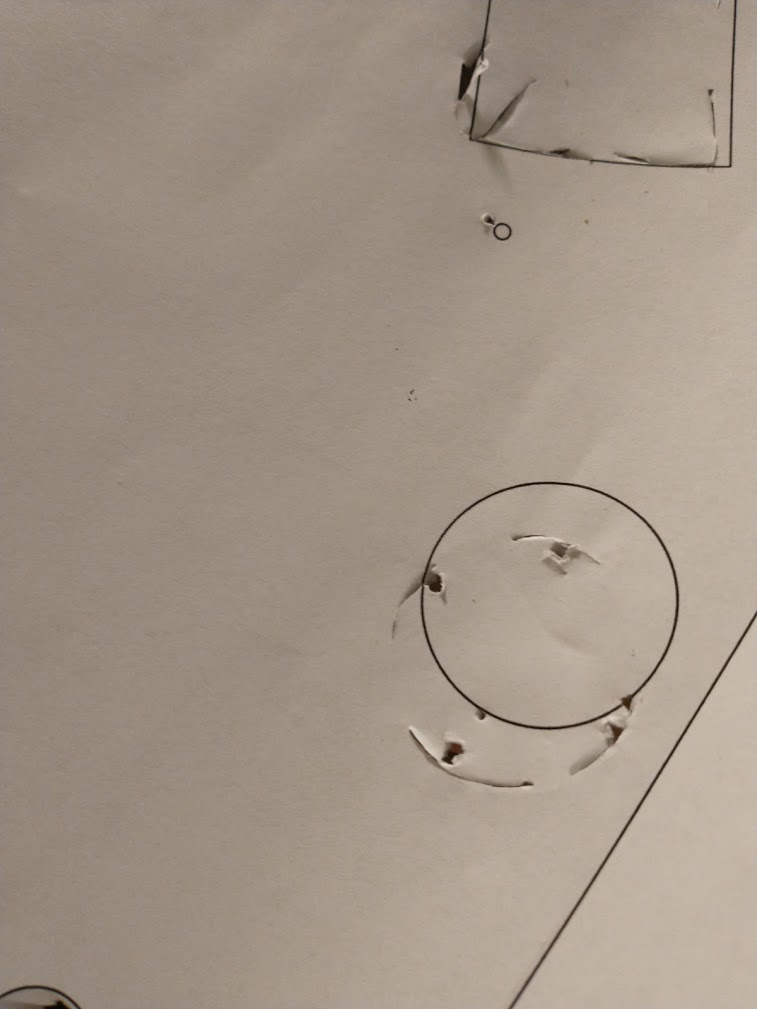

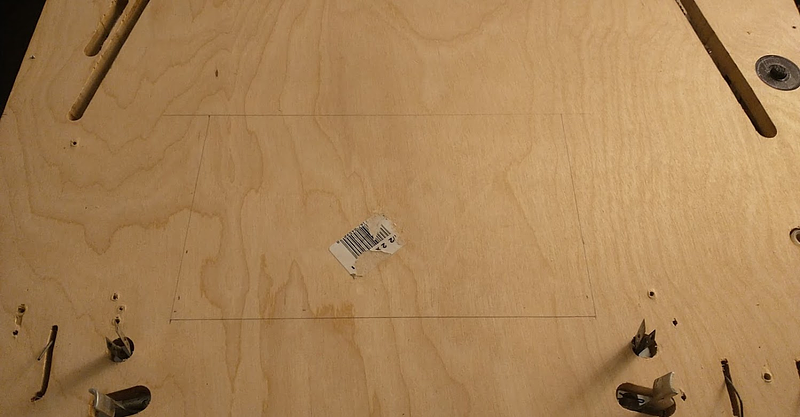

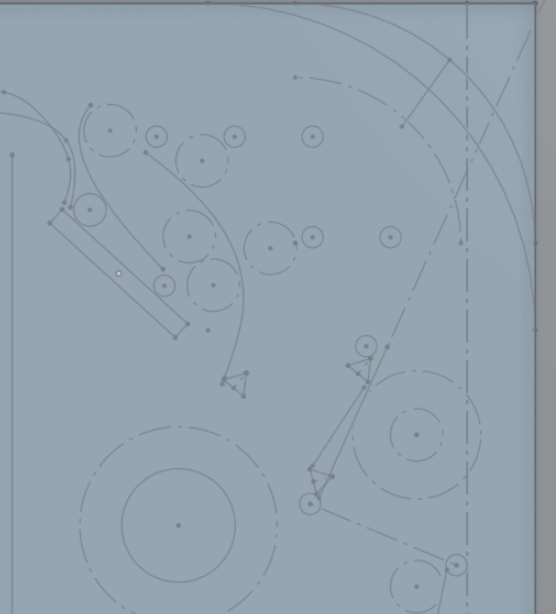

Having no luck with the flipper resistors, I went to the nuclear option regarding the heat buildup under the playfield, and installed 6 computer fans over all the holes on the cabinet to provide some airflow. Of course, it somehow had zero effect. So, as a last ditch effort, I ordered some PET-G to make a new playfield covering, thinking maybe the acrylic was the issue. To further correct some of the issues with my previous acrylic plastic, I took some rubbings on a large piece of paper and got it scanned at staples.

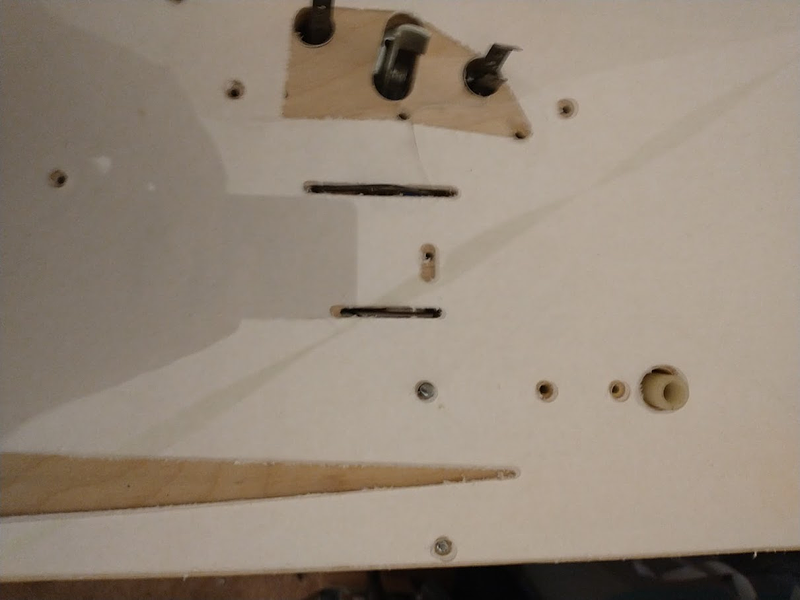

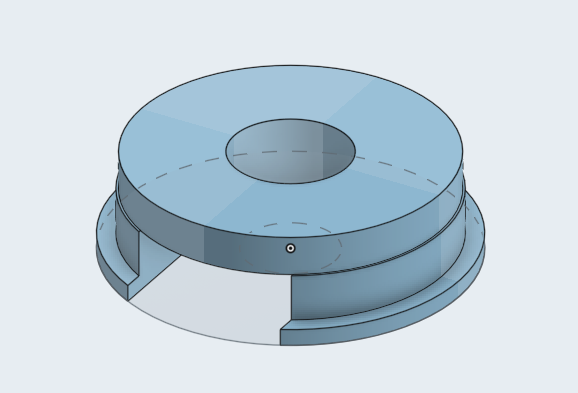

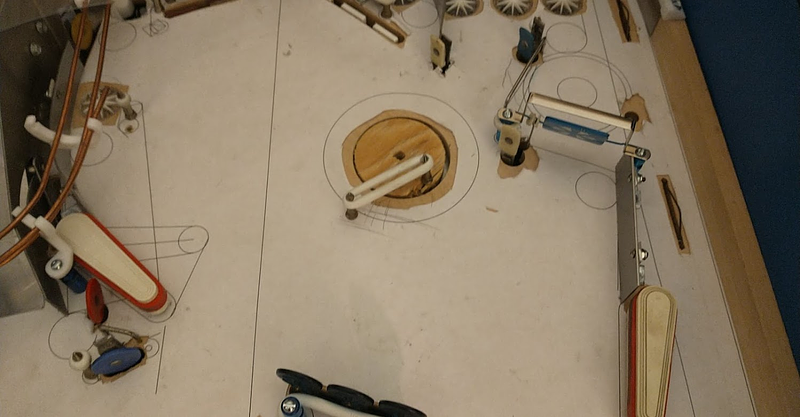

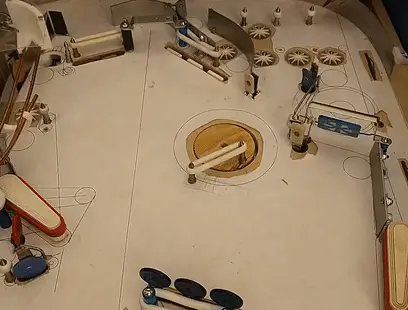

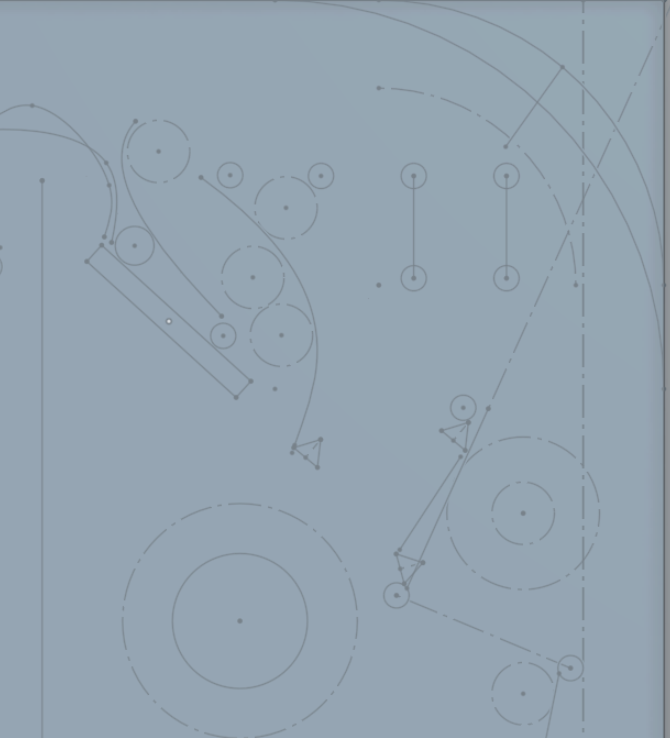

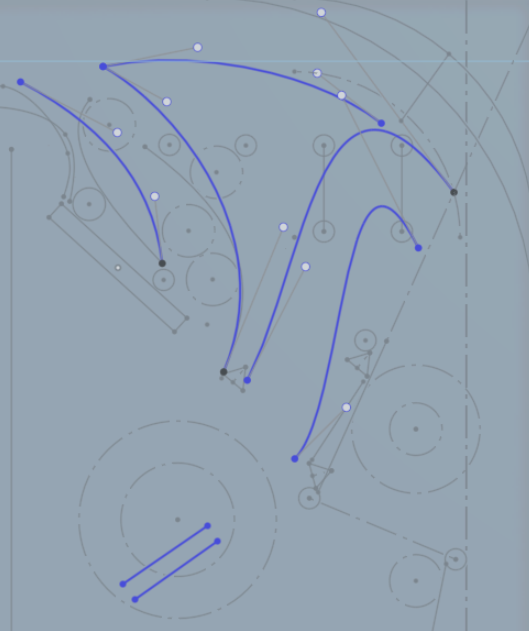

I'd done similar before with a piece of paper that I'd punched holes in to mark the positions of screws, etc, but some of those were missed or didn't come through well, and I'd also added the holes for all the screens since then, so I needed an update. Based on that, I made an updated CAD file:

Sourcing the PET-G at a reasonable price was a bit of a pain, so I didn't want to waste it. Luckily, I found that I could make serviceable test cuts with my CNC router on plain paper, so I did a few iterations with that to fine tune things. The cuts weren't perfect (rough edges, occasional tears) but it was accurate enough to be useful

Once I was satisfied with all the positioning, I cut the full playfield in PET-G

After reassembling everything again, I did a test game..... and the PET-G buckled just like the acrylic.

So I needed a new approach. Long term the clearest solution here is just to glue everything down, but I don't have any art ready yet and I'm not sure if I could apply and later remove the glue cleanly without damaging the wood. I'd been hoping to eventually cut a new playfield wood with the CNC, but as I continue to have problems with the depth of cut with the PET-G I don't have much confidence in getting that working quickly, so I'm still stuck with my original hand-cut plywood right now.

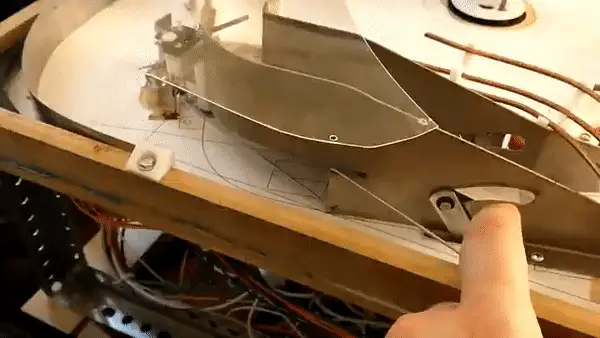

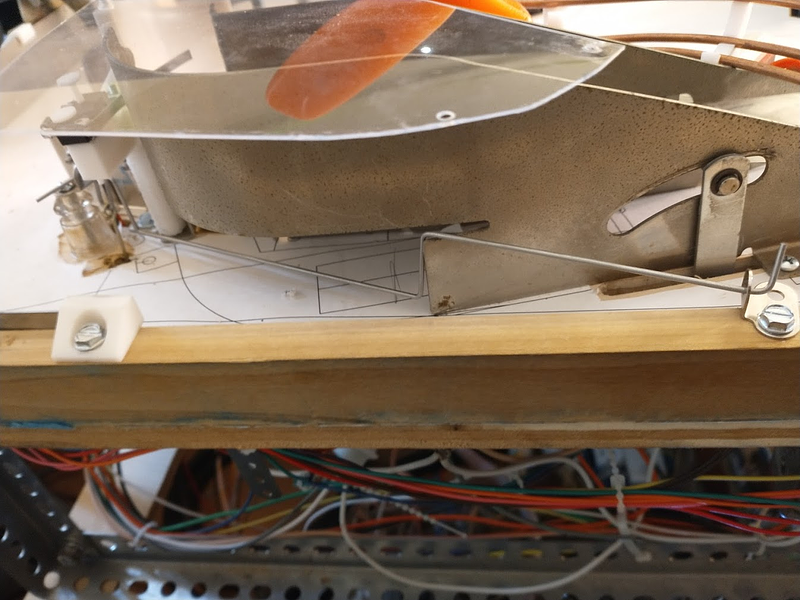

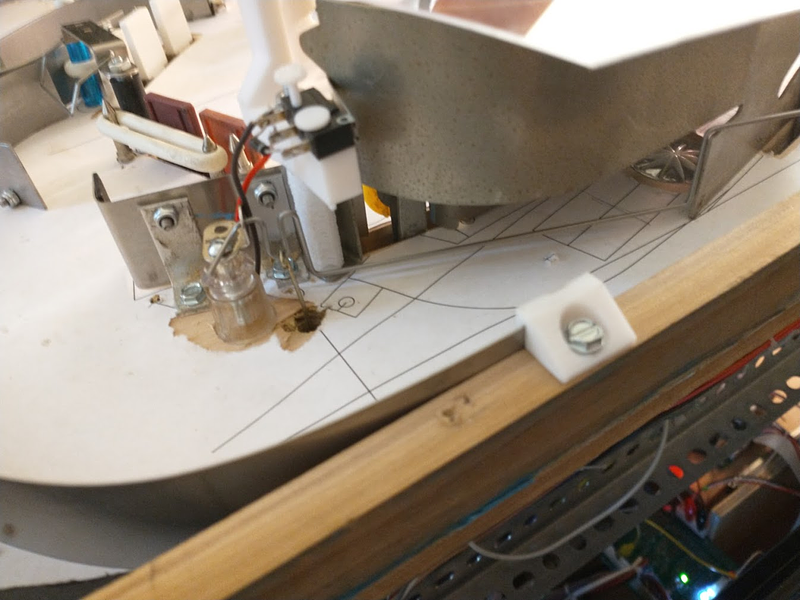

So I decided to go the other way right now, and instead of attaching everything down even better with glue to prevent the buckling, I decided to just attach as little of it as possible, and make a plastic more like the standard playfield protectors sold for other pins. The new protector would only be held down at three positions (the three posts closest to the center of the playfield), which should keep it from moving, while allowing the plastic to expand/contract as needed to keep from buckling.

Originally I'd rejected this idea when starting to experiment with the plastic covering, as I didn't want the ball to 'sink in' to the empty areas over the screens. But that was also with a thinner material. I'm now using 0.06" plastic, which is much more rigid, and doesn't seem to bend much as it supports a ball over the 9" screen even without being attached down at both sides, so I think it should still play fine.

Now... more test cuts!

Unlike with the full plastic where I only needed to worry about the holes for the screws, here I need to match up to every contour of the ball guides, etc. Which of course I mostly bent by hand/eye and don't have any accurate digital files for. And of course I didn't think to etch them onto the plastic when I got it scanned either. Not a big deal though. I can give even 0.2-0.3" of space around the edges of things safely without affecting the ball (although it looks a bit weird), so I don't need to be super accurate here. And thus, I cut another sheet of PET-G. And also order 2 more spares since I'm now out of stock and I hate to wait for things to ship.

Some things weren't quite as accurate as I thought, but in the end there weren't any major issues. Only two places touched the edges of the plastic, and since it's PET-G it's easy to trim by hand

So now I start reassembling the whole playfield AGAIN to make sure that this still all plays fine. I'm fairly confident this should work though.

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

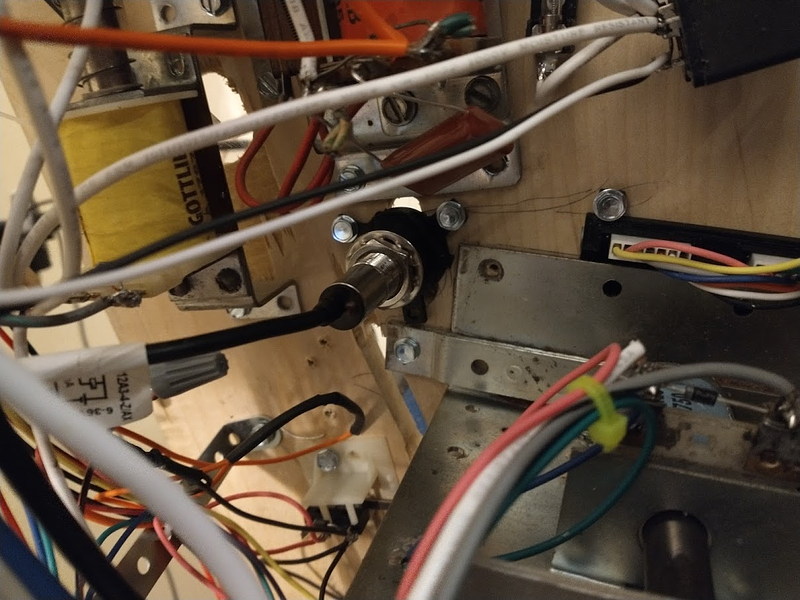

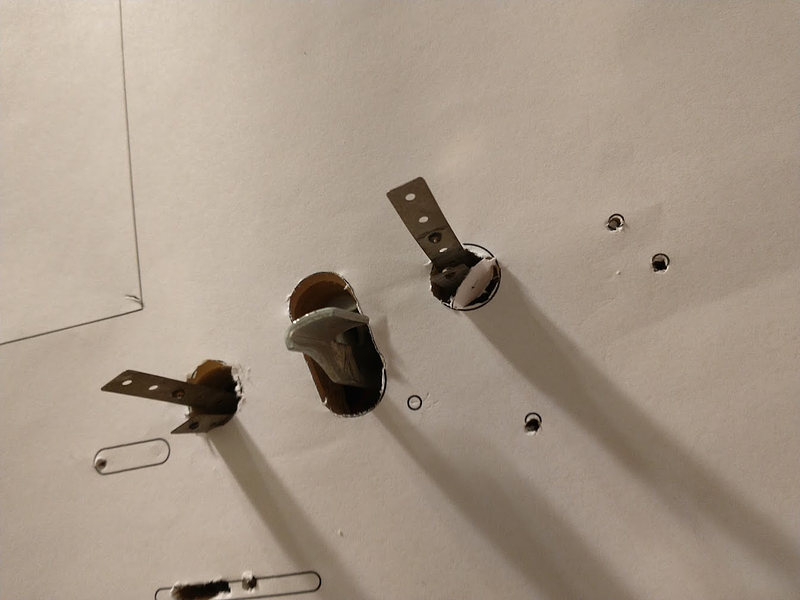

For a long time now I've had my start button doubling as an action button (I disabled restarting a game, and then made the start button trigger the action button code snippet once the ball has been plunged), which has been a bit annoying, and hopefully is part of the reason why playtesters keep forgetting I have an action button (doh!). I've also been stealing a lockdown bar from my Whirlwind whenever I do playtesting because... I don't have a lockdown bar for this game!

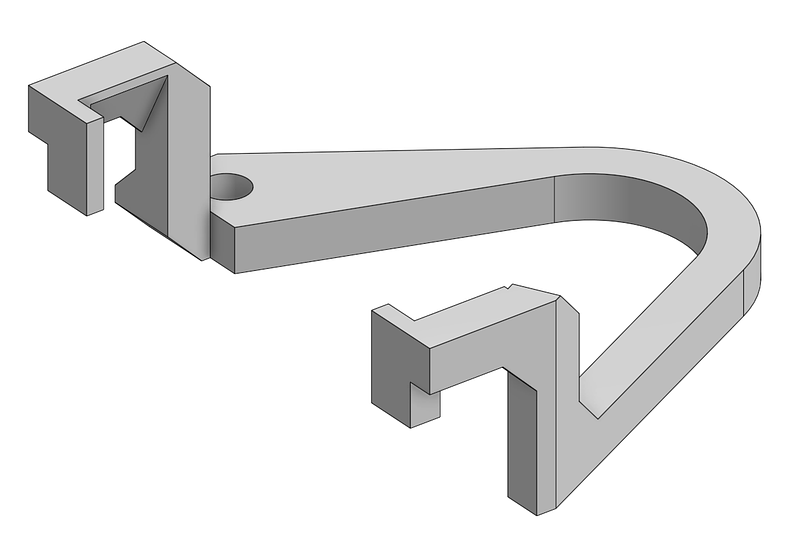

What I did have though is a really rusty spare lockdown bar sitting around. So I sandblasted it, then following ![]() McSquid's advice from his Sonic homebrew, drilled a hole in the bar, painted it black, and successfully mounted a flipper button in it using a 3d printed bracket.

McSquid's advice from his Sonic homebrew, drilled a hole in the bar, painted it black, and successfully mounted a flipper button in it using a 3d printed bracket.

Then I had to get a switch in there!

No problem, just drill two holes in the receiver to mount it, and then squeeze a switch in (with less than 1mm of spare room), snake some wires down, and wire it up. Working good so far, we'll see how it holds up during play

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

Small updates...

Added a bunch of high scores to the attract mode. Besides stuff like a regular leader board, "best spinner rip", "most hands won", etc I also added a 'lowest scores' board for fun, since technically players can do so bad at poker that they end up in the negative. Could be an interesting thing to compete on!

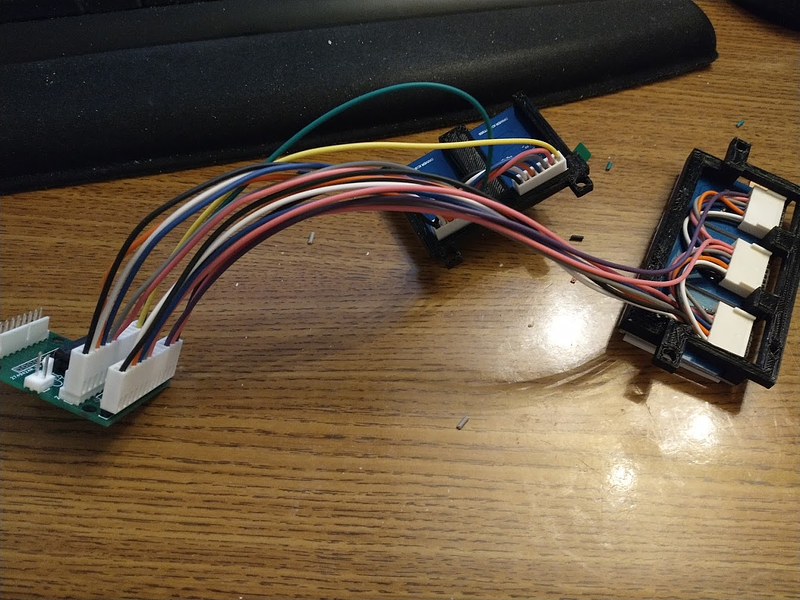

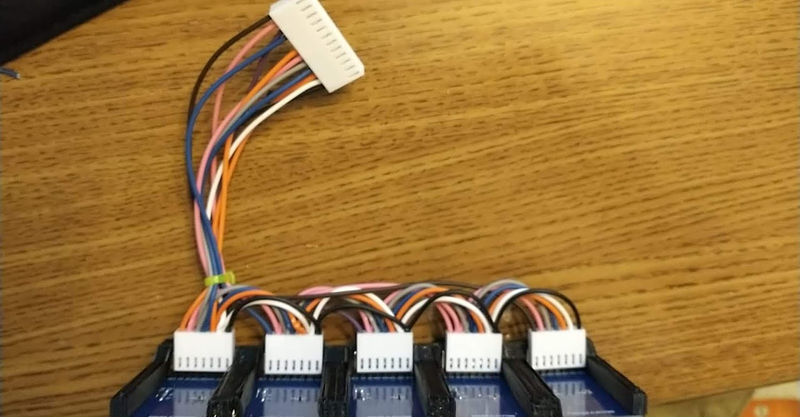

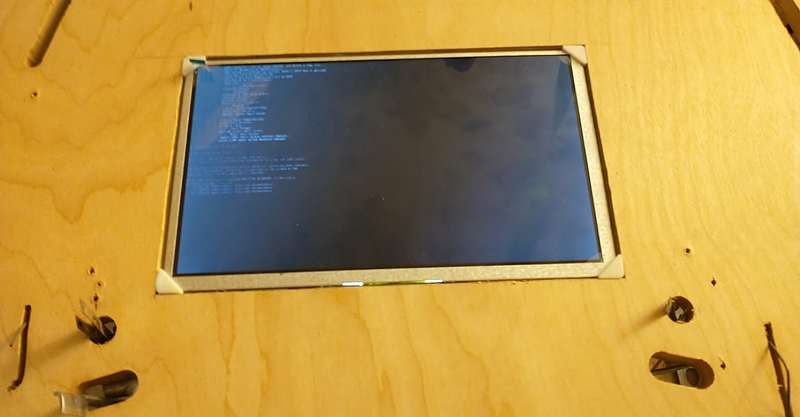

Had another playtester over for a few hours of gameplay. I noticed they weren't really reading some of the mini screens much. Part of that, I think is just because they're generally really weird. It's hard to get used to looking all over the playfield to see what the writing says. But there's a second issue, which is that some screens were just hard to read. Part of this is due to the viewing angle I think. Displays towards the back of the playfield are both farther away and at a more extreme angle, so they lose contrast. Both of those make them harder to read. But the other thing I realized is that my larger rectangular displays were much dimmer than the smaller square displays I was using for the cards themselves. Each of these displays has a BL pin on them, which is supposedly for the backlight, but I was never able to find much documentation about it, so currently I have it disconnected, and the backlight does seem to work. I wondered if maybe the larger displays needed some extra power on that pin or something, so after failing to find any solid info, I gave up and just started sending random signals in to see what happens. It seems like the BL pin is an active low 'disable' pin to turn it off. Not really useful to me. But while trying to find documentation on it, I also saw some places talking about 3.3V vs 5V. Apparently the actual controller chip on these display boards can run off either voltage, and some manufacturers include level shifting chips so either voltage can be used to communicate. But again, I had no documentation for my boards, which I'd sourced from a random shop on ali express from china in bulk. So I figured, only one way to know for sure!, and just hooked one of the displays up to 5V to see if it smoked or not. Luckily it worked fine, AND got brighter! So I had to rewire all my displays get 5V for power instead of 3V :/

Playtesting also revealed a lot of switch issues. My modified small rollover buttons keep getting stuck in a few places, leading to the game going crazy or balls getting stuck, or sometimes just missing switch hits. I'm hopeful that when I get my CNC fixed and cut a new one, I can align these better, but I'm getting really tired of dealing with issues regarding this. Need to come up with a more permanent solution. I've ordered some proximity sensors to play with, and I also have some other ideas regarding the rollover design to play with.

Around the third hour of playtesting, my new thicker acrylic playfield cover started buckling slightly ![]() I'm not sure what causes the heat to do this at this point. I left it for like 8 hours plus with the game on, and had no issues, but now after a few hours I'm having issues? My only other thought at this point is that maybe it's the heat of the flipper coils themselves causing the issue. I've noticed that, especially after long games requiring lots of cradling, the lower flipper coils get quite hot and you can smell them sometimes even, despite the EOS being adjusted properly. I think this is due to the capacitor I've added to the power supply to give them more power. I've ordered some high wattage resistors to attempt to wire in series with the hold winding in a way that they'll reduce the strength of the hold circuit (which is already plenty strong) without affecting the power winding. If that doesn't work, then I may have to mount some tiny fans like people are doing on newer games in order to cool them off.

I'm not sure what causes the heat to do this at this point. I left it for like 8 hours plus with the game on, and had no issues, but now after a few hours I'm having issues? My only other thought at this point is that maybe it's the heat of the flipper coils themselves causing the issue. I've noticed that, especially after long games requiring lots of cradling, the lower flipper coils get quite hot and you can smell them sometimes even, despite the EOS being adjusted properly. I think this is due to the capacitor I've added to the power supply to give them more power. I've ordered some high wattage resistors to attempt to wire in series with the hold winding in a way that they'll reduce the strength of the hold circuit (which is already plenty strong) without affecting the power winding. If that doesn't work, then I may have to mount some tiny fans like people are doing on newer games in order to cool them off.

On the subject of heat, I've also gotten some 120mm computer fans to try to get some airflow moving through the whole cabinet. Even if running the electronics minus the flippers isn't enough to affect the playfield, it still does get quite hot in there and I don't like it. I've also realized that my RPi is mounted upside down on my MPU board, which probably isn't helping things. RPi 4s apparently already run hot, and I had installed some aftermarket heat sinks on mine, but a passive heat sink on the CPU doesn't matter that much if it's upside down. So I've designed a new version of the MPU board which will mount above the RPi to fix that. It should also give me enough space to give the RPi a small dedicated cooling fan if needed.

Pintastic New England has announced their next show will be this November, so bringing the game there is my new goal for the machine. I think it's achievable, in some form, but that means it needs to be able to survive a full day of the public playing it without me being around. At a minimum, I need to fix all these ball hangups. That'll mean fixing some switches, tweaking a few areas of the game slightly, and installing plastics and an apron in case of air balls. I also need to get the action button installed on my lockdown bar to get that presentable. If I can get the game bulletproofed, it'd also be really cool to get some cabinet art, but that might be beyond my capabilities right now. Time will tell...

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

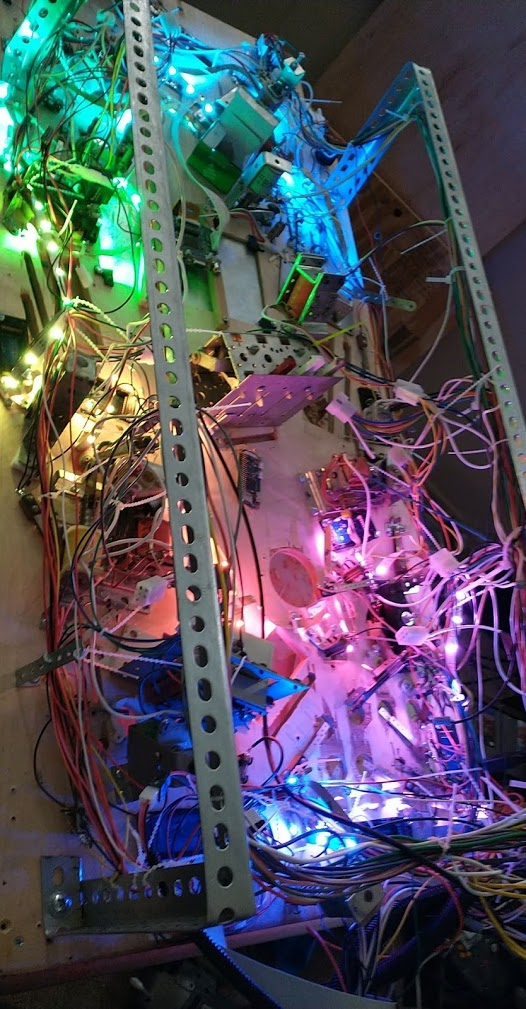

When I started working on this machine, I had a pretty simple power system. 3V for my boards, 5V for the RPi. Both coming from an ATX PSU. 25V for solenoids from an old gottlieb transformer. Power switch turned everything off, as normal, and I added an extra switch inside to cut the high voltage if necessary. A few early mishaps with coils locking on while the playfield was down made me realize the high votlage switch inside wasn't that easy to access, so I added a secondary power switch on the bottom for the high voltage. Very useful, I recommend that for any homebrew... Then I added 12V for the screen. And then 12V for the audio amp. Then another 3V line for the mini displays. And another 5V line for the LEDs. And another 5V line for the second RPi to power the mini displays. And another 12V line for the light strips. Each of these had its own fuse, etc, all coming from the ATX PSU. Luckily I designed a power splitter for the ATX-24 connector that could support all that, which has somehow managed to be future proof enough to keep me going and keep everything vaguely organized. Then I had to move each Pi to its own separate supply, due to noise issues coming into the amp.

However, there's a problem with that. I have three separate processes across my two Pis that currently need to be manually started, as I haven't made them automatic yet, and they sometimes need some massaging. My Pi also has a weird issue where about 1/4 times you power it on the OpenGL drivers just... won't work. I can't find any solution for it, so my only real option is to just repeatedly reboot the Pi and restart the processes until they work. Plus I have another weird issue that I've never been able to track down where the Pi won't boot if the cabinet switch matrix returns are connected. Can't figure out what could be causing that, and I'm hoping that a new MPU board revision will magically fix it. But in the meantime it means that, when I turn the machine on, I need to first reach in and unplug a connector, wait 5 seconds, then plug it back in. Then I walk over to my computer, SSH in, start all my code. If the driver is dead, I need to reboot, then pull the connector again. Sometimes this can end up being a 5-10 minute ordeal. My solution? Just don't turn the game off! So instead I reach in and unplug the LED power supply, light strip power supply, and mini display power supply. Then I grope around and find the power button on my screen and turn it off, and then I reach under and kill the high voltage. Game now appears 'off', but the Pis are still running. Easier, but it still leaves me in a situation where sometimes I avoid playtesting my own game because it's too much of a pain to turn on! So that had to stop. I realized that, in the end, all the systems I want to turn off are coming through the ATX supply, and my Pis are on their own supplies, so really I just need to turn the ATX off. If I'd planned this from the beginning I probably would just install a third power switch, but I don't feel like taking everything apart again to do that. So instead, I replaced my internal HV switch (which I never use anymore) with two extra 'service' outlets, and plugged the Pis directly into them. So now the Pis are just 'always on' as long as the game is plugged in, which is fine with me. Meanwhile I have a primary power switch which kills everything in the game except the Pis, and an extra switch to turn the HV off if needed. Much better

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

In between these playfield changes I've been making a bunch of tweaks to the code. I added another multiball, rounding out the main hands (straight, flush, and full house). Added a mystery award which is really fun but hard to explain via text. Lots of tweaks and bug fixes. But mainly I've been working on sound!

The game now has more than 100 sound effects and callouts (and still many to go). At first I was agonizing over trying to find some good sounds that fit everything well, etc, but I've realized that you don't need a 10/10 sound effect to add quality to the game. Even a 5/10 sound effect is way better than no sound effect, as long as you've got them everywhere. Sadly I've also realized that making 5/10 sound effects is way harder than I'd have guessed. I've spent a bunch of time with a mic, a few poker chips, and a deck of cards, making random sounds by hitting them against each other, etc, trying to get some good, real, 'poker' sounds to put in.

On the software side, I did some research into how other games handle sounds. Playing one sound is simple enough, but it seemed like if I just played every sound that came in (and every call out, etc) things would get messy. You never want two callouts at once, and I figured you may not want multiple sounds at once either, so there needs to be some system in place for that. Sadly, it turns out that getting Java to play a sound, and then kill that sound mid way, adjust volume on the fly, or even just get the length of the sound are all more complicated than you'd expect. I ended up writing a custom mixer to combine a music channel, a voice channel, and a few sound effects channels together on the fly, which gave me the level of control I wanted. Currently I've got a simple system set up where, if a sound is playing on a channel, nothing will interrupt it (after like 50ms). If you try to play a sound but there's already another one going, that new sound is ignored. If two sounds come in at once (which happens a lot since I might have the base game make one sound effect, but then the mode you're in at the time makes another), I just choose the longer one. Originally that was a hack until I could code some proper 'priority' system in to let me manually order the sounds but so far it's worked surprisingly well so I haven't had the need to go further. I've also implemented some ducking, so the music and effects will get quieter when there's voice playing, and the music will get quieter when there's effects playing. Took a bit of play to get that to sound natural, but once it did it worked well.

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

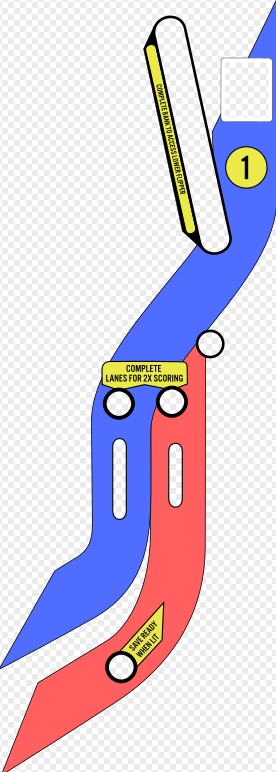

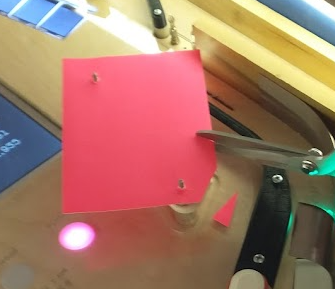

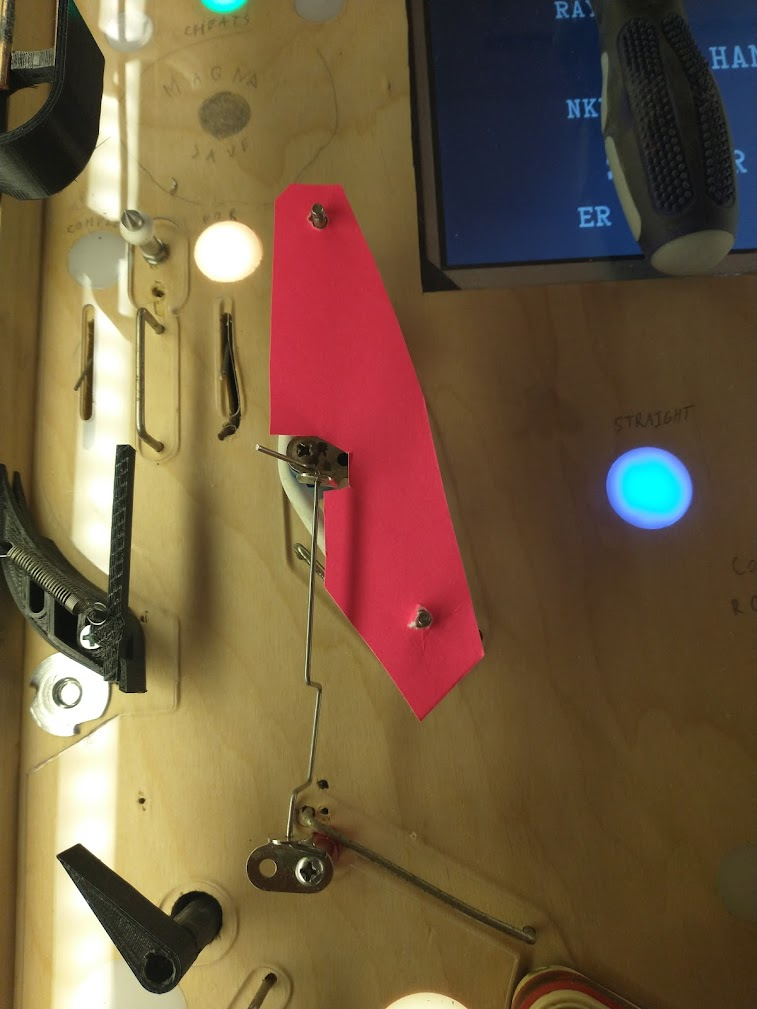

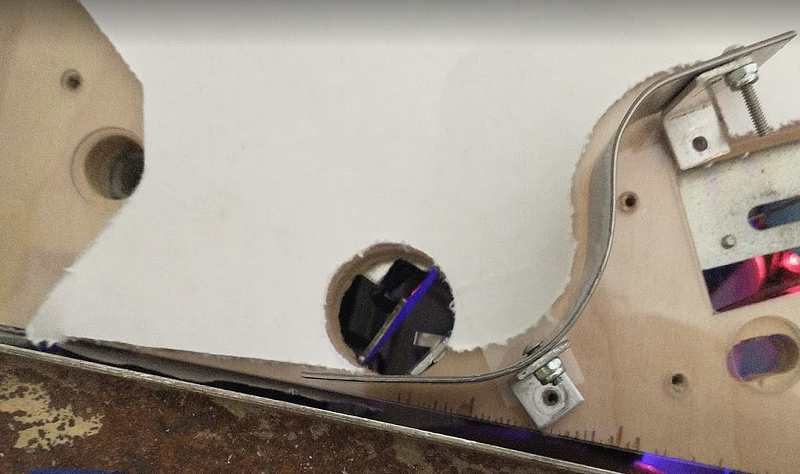

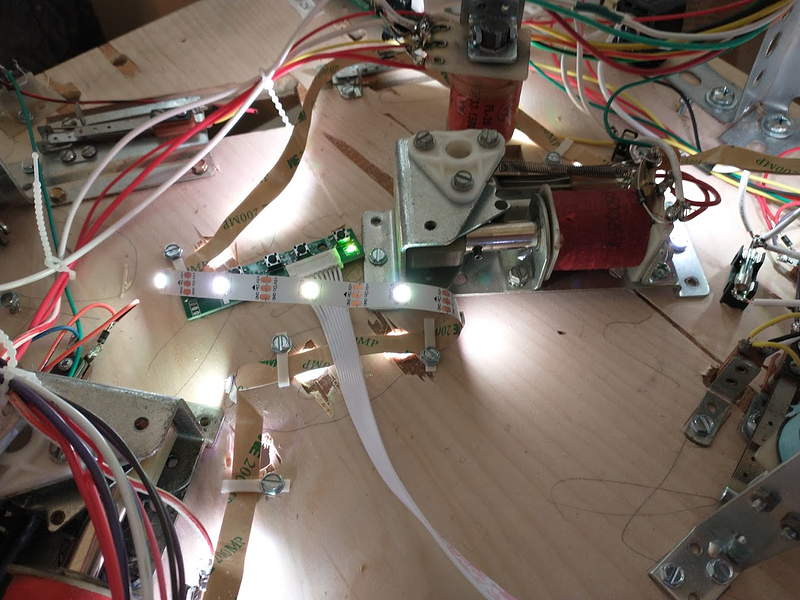

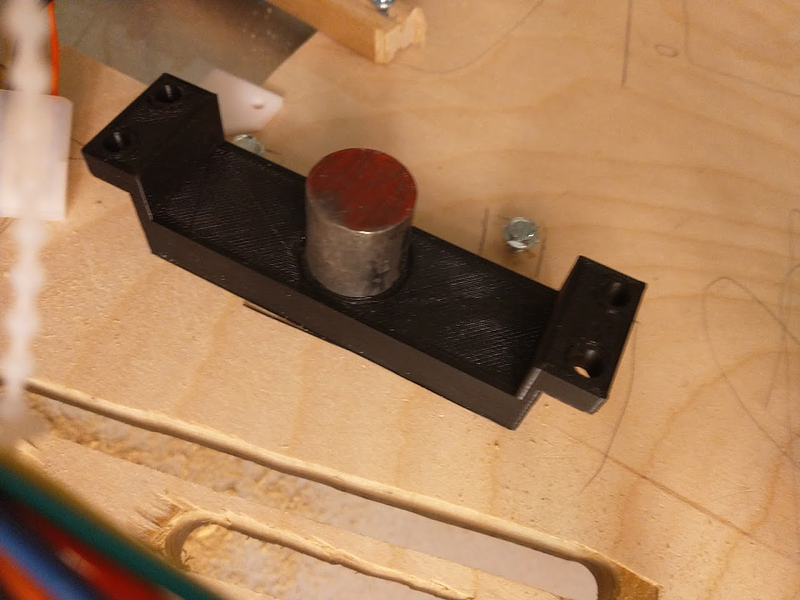

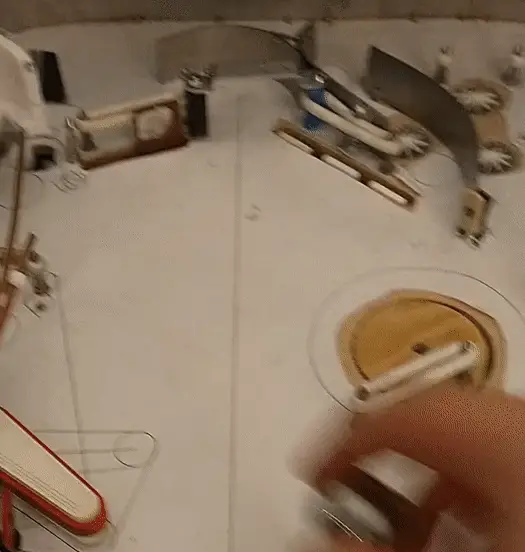

Sometimes to get an idea as you fall asleep saturday night.... and then spend your sunday making it work

My upper magnet has never worked how I wanted. My goal was basically just to be able to shoot the left orbit and feed the upper right flipper. Magnet couldn't grab the ball. So I added the up post. That wasn't 100% reliable at even catching the ball, and when it did, the magnet still couldn't grab it somehow. So I cut the hole all the way through the playfield to give the magnet more power. Didn't help at all. When I made the new plastic playfield, I didn't even bother cutting a hole for the up-post. My thought was, instead of shooting the left orbit to feed the magnet, I should be able to shoot the spinner, and use the spinner to activate the magnet, since the ball would basically be in perfect position over the magnet when the spinner switch closed. But that, of course, didn't work at all. Magnets suck! I ripped out the magnet. Maybe I should just forget this entire idea about feeding the upper flipper. I basically only ever used it for one of my four multiballs which had a jackpot only hittable from the upper right flipper; it seems like a waste to put a whole mech in just for that. But the multiball was based entirely around that upper flipper shot (it's basically a lawlor throwback themed multiball), so I'd have to rewrite that whole multiball somehow. Plus then I'd have no need for the target under the upper left flipper which I've gone to a lot of pains to implement. There'd barely be any reason to have the upper flipper at that point; all it'd be useful for is trying to feed back to the upper playfield area if you drained out of it to the right.

So I needed some other way to feed the upper flipper. Before, on the left orbit, approach, I'd tried to figure out how to work a diverter in there, but there just wasn't room any way I could find. While watching the magnet fail to catch the ball via the spinner shot I thought, it'd be cool if I could like, have a raise-up captive ball. I've always liked how captive balls feed flippers but you don't see them in too many games. But there was no room in front of the spinner to try to make something like that due to the screen+lights. And I couldn't really put it behind the spinner since I had a giant hole there from the magnet and you wouldn't be able to see the captive ball well to aim for it. But I figured you don't really need a captive ball at all. Really you just need a wall for the ball to hit to fall back to the upper flipper. A single drop target that could raise up would be cool, but I think the rebound would be too fast. I really just want to deaden the ball and let it gravity feed for the shot to be makable.

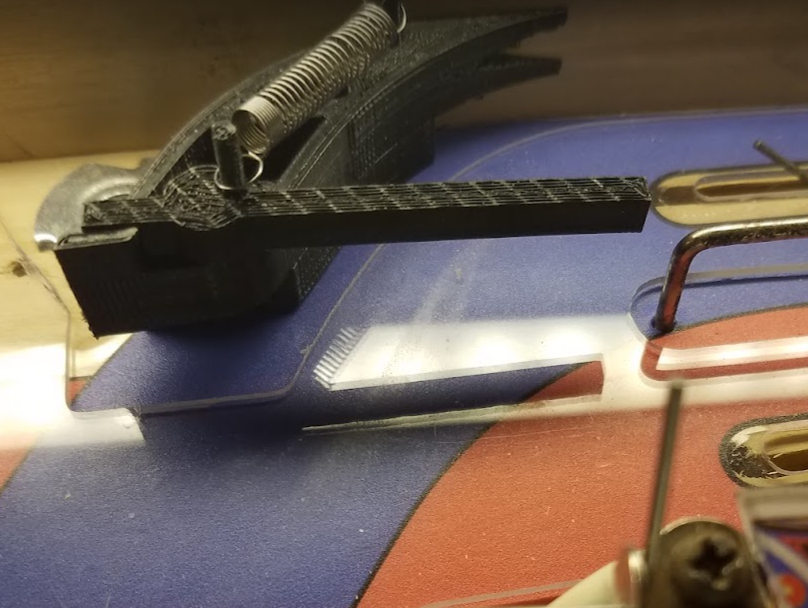

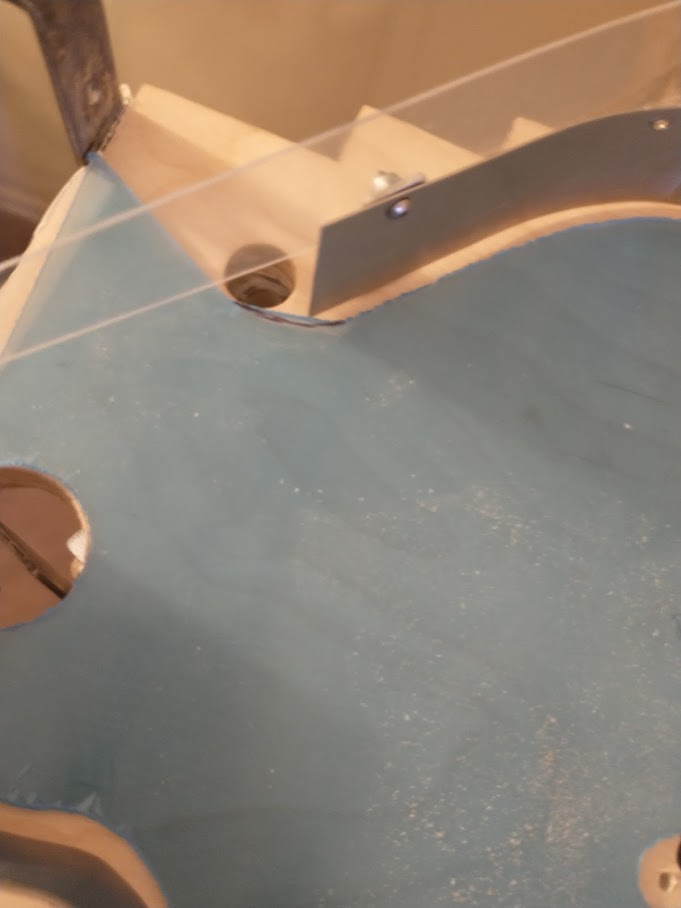

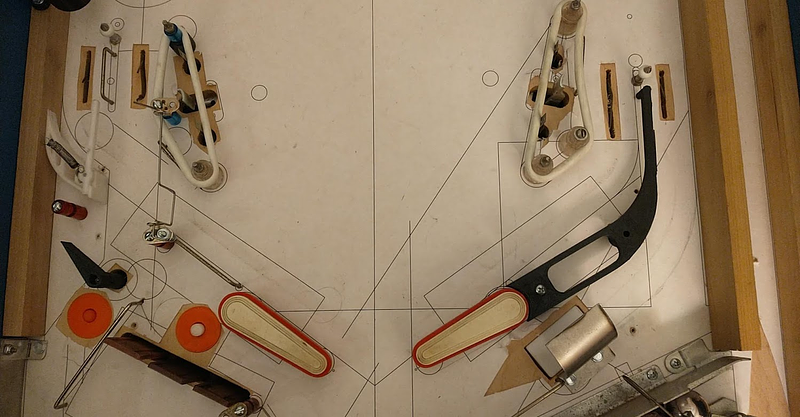

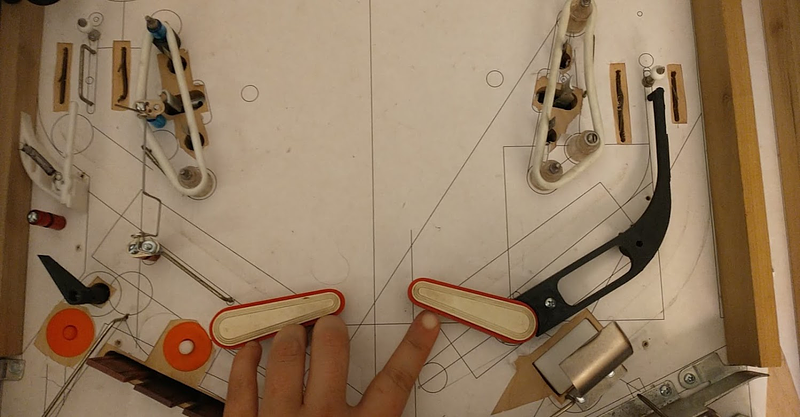

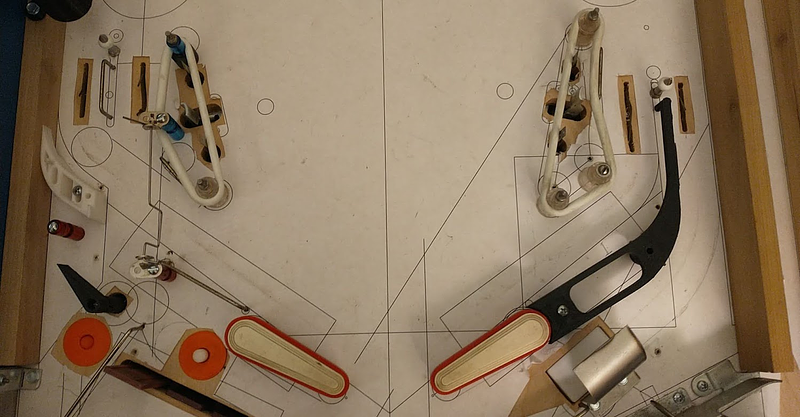

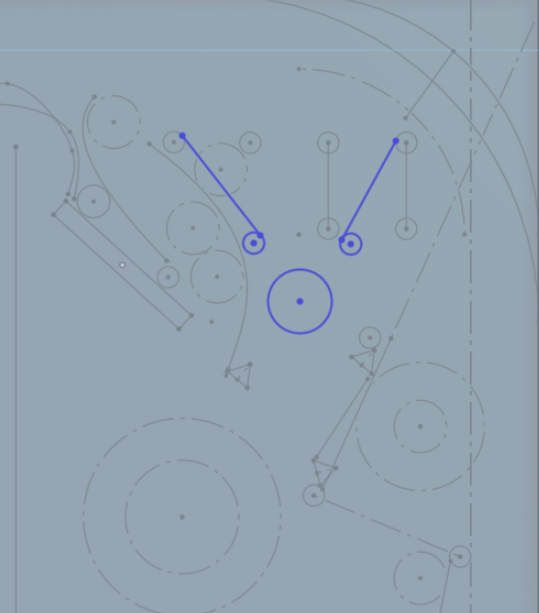

Thus:

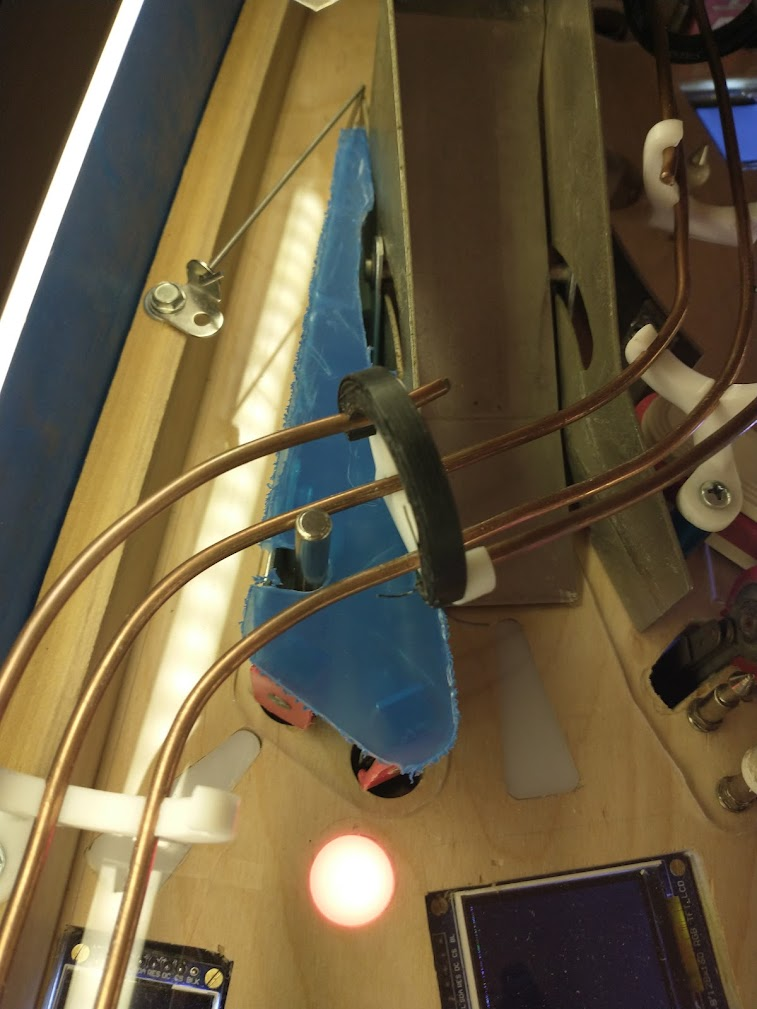

In the up position, the ball goes underneath just like normal. When it's down it sorta catches the ball and lets it fall back down again. It isn't always a perfect feed but you can always get a flip at it

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

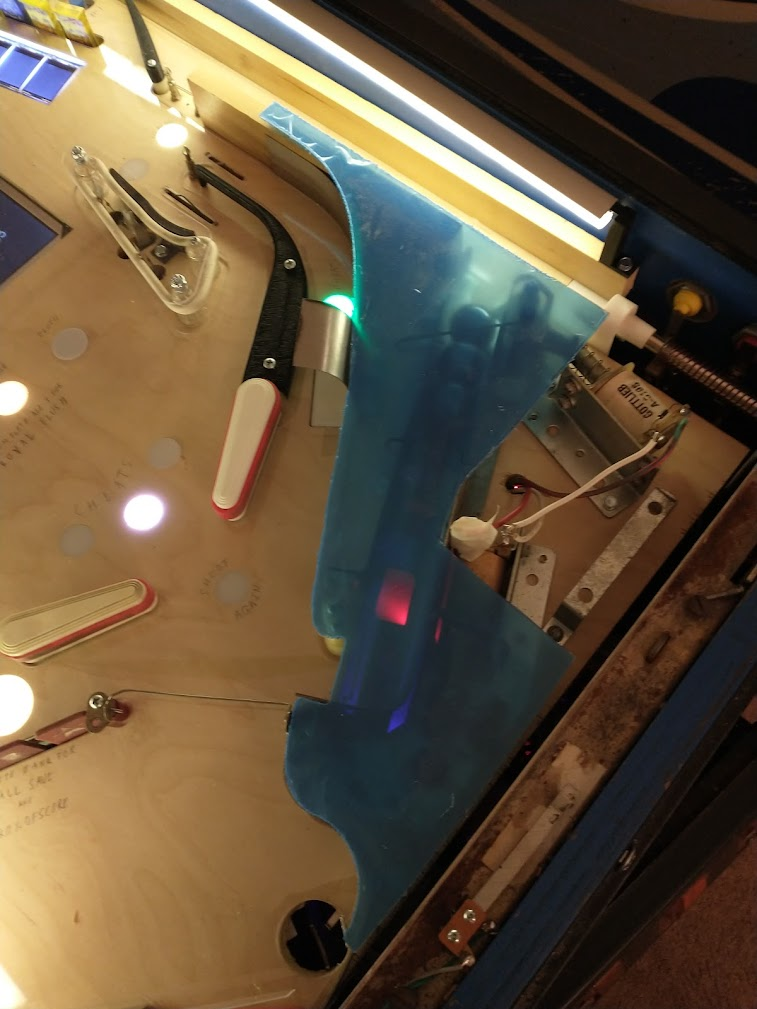

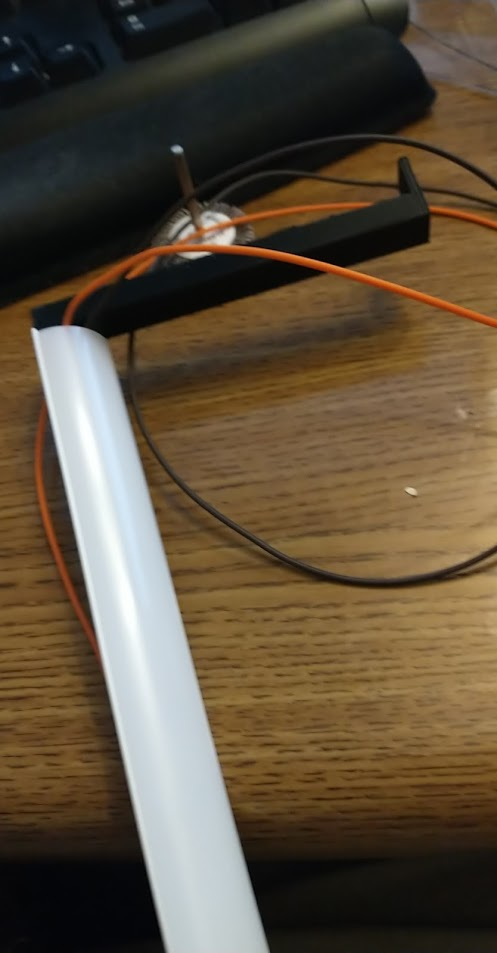

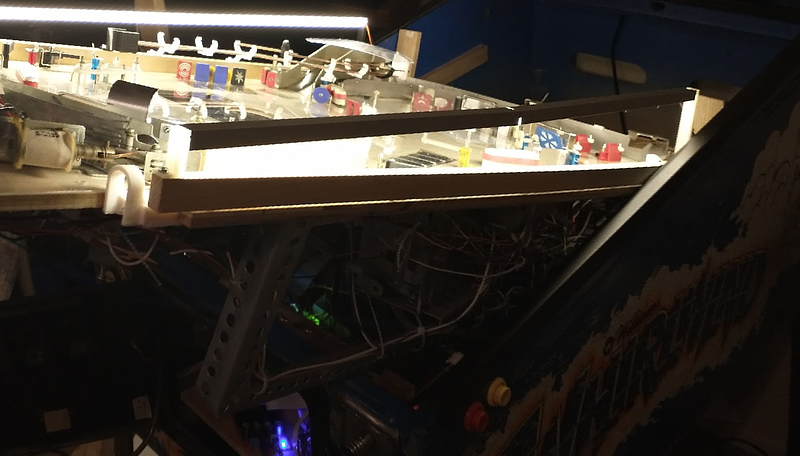

I'd been considering something similar, and then I saw these on the Sonic Spinball homebrew and got a link to the strips, so I added some light strips along the sides for GI. Actual GI bulbs had never really been in the plan, since they'd need to squeeze into some tight spots. Plus there aren't that many spots to put them, which confused me a bit at first. When you look at the playfield though, other than the slingshots and around the ramp, there's pretty much no spaces where a GI bulb could even go. When designing I like to make the most of the space, but maybe it's a bit too far?

I got some plain warm white LED strips, and some V channel guides for them:

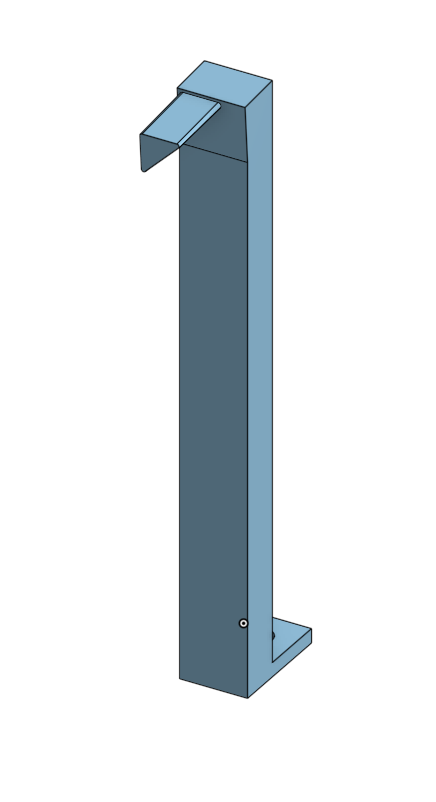

Then I 3D printed some supports for them that stick into the triangular hole in the back of the channels

I mounted them onto the side rails, instead of to the cabinet like Sonic + Pinstadiums do, so there's no need to remove them when lifting the playfield. They sit about a millimeter below the glass

The illumination doesn't cover the whole playfield quite as nicely as I'd like, but if I wanted anything else I think I'd need to custom design some channels to aim them at like a 30 degree angle instead of the 45 or 0 angles commercially available.

If I'd planned these from the beginning, I might have made some custom metal channels, with some stronger metal mounting posts, so that I could actually set the playfield upside down on them for servicing (and maybe some spare attachments at the front to make it even). I like the idea of the playfield having complete protection when removed from the cab. I've got the support rails on the bottom covering that side, so I can easily pull the playfield out, set it down on a table or on end, and not worry about the mechs, but currently if I want to set it upside down I need to use the wooden back wall and manually install some more wood posts to the hangers in the front, which isn't too convenient.

I'm not sure if that'd be worth the effort though, and I'm not sure how satisfied I am with this technique. For a whitewood like this that I've been winging the design on a bit, they're really nice. No need to make concessions for them in your plans or worry about wiring, etc, but they also have an annoying glare on the playfield. It's especially noticeable here since I have a perfectly flat acrylic sheet on the playfield, while a clearcoat would probably be a bit more subdued. The glare isn't in the main play areas, so it's not a deal breaker (they're better than no lighting!), but I'll have to think more about other options or tweaks to this in the future

While the coverage isn't completely even, these new lights do illuminate the back wall (or lack thereof!) though, so I'll need to think about that more at some point. Technically you could airball right over the back wall and into the cab currently, but I've never seen that happen. It also illuminates that there's a ton of dust on my playfield :/ Sadly that's what happens when your game sits for months with no glass on it, and I don't think that'll be changing any time soon. I may need to station a shop vac nearby for convenience though.... There's still a lot of ball hangups, etc currently so I couldn't really have the glass on for too long anyway. Actually I don't even have a sheet of glass for it since I stole it for another game to replace some non-tempered stuff; and I don't have a lockdown bar for it either. At some point I'm going to need to put a focus on getting some glass, getting a bar, installing an action button, and then dealing with all the stuff that keeps me taking the glass off: I'll need to make some plastics (easy, but may need to swap some posts to mount them), add some more stuff to prevent airballs from getting stuck places, make an apron of some kind, etc.

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

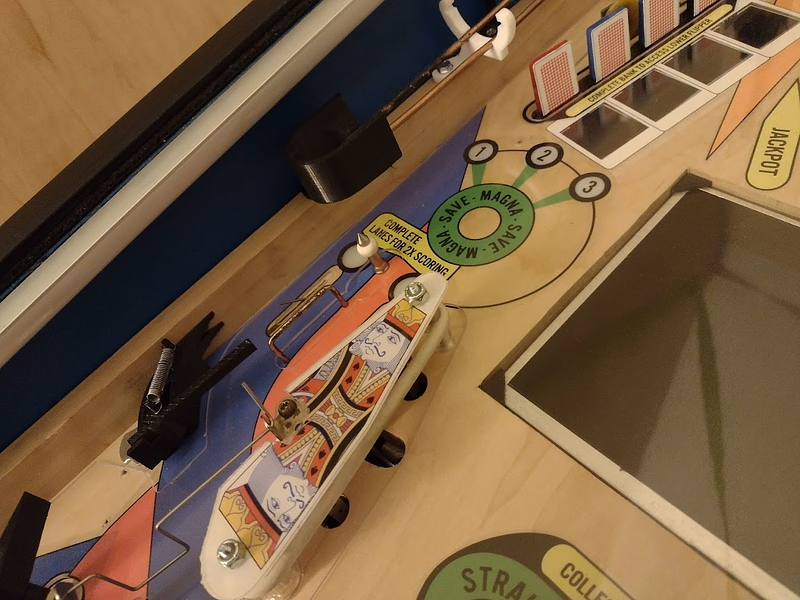

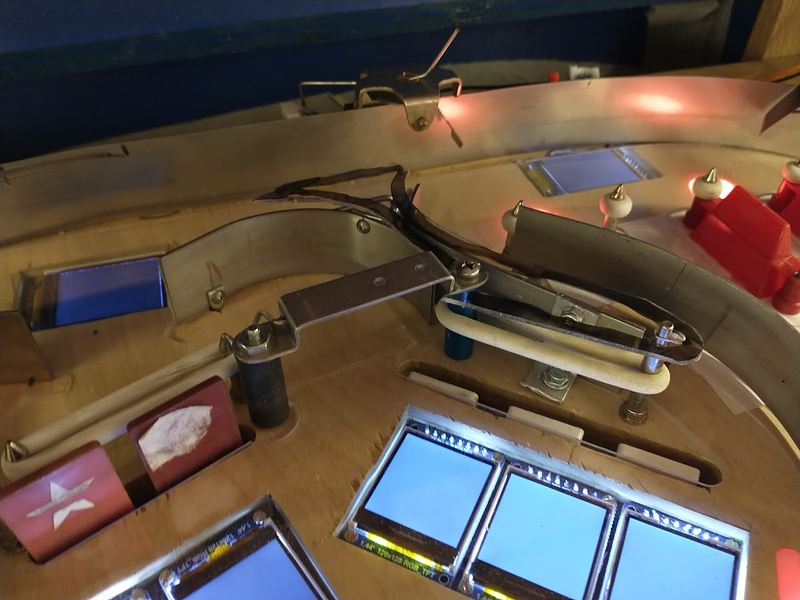

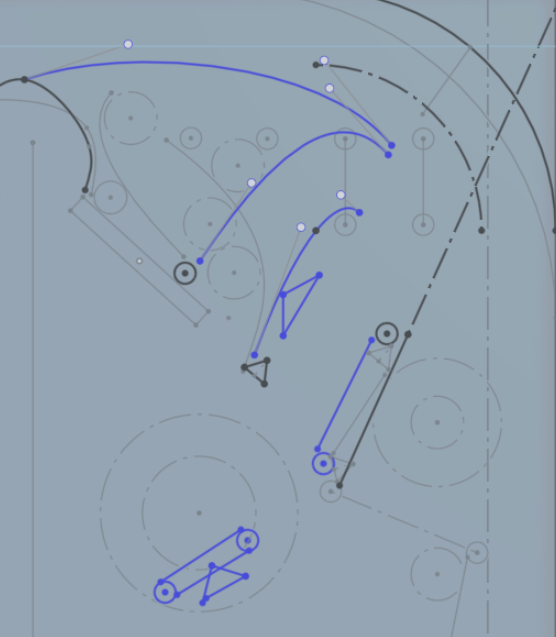

While I had the playfield apart, I also made a few layout tweaks

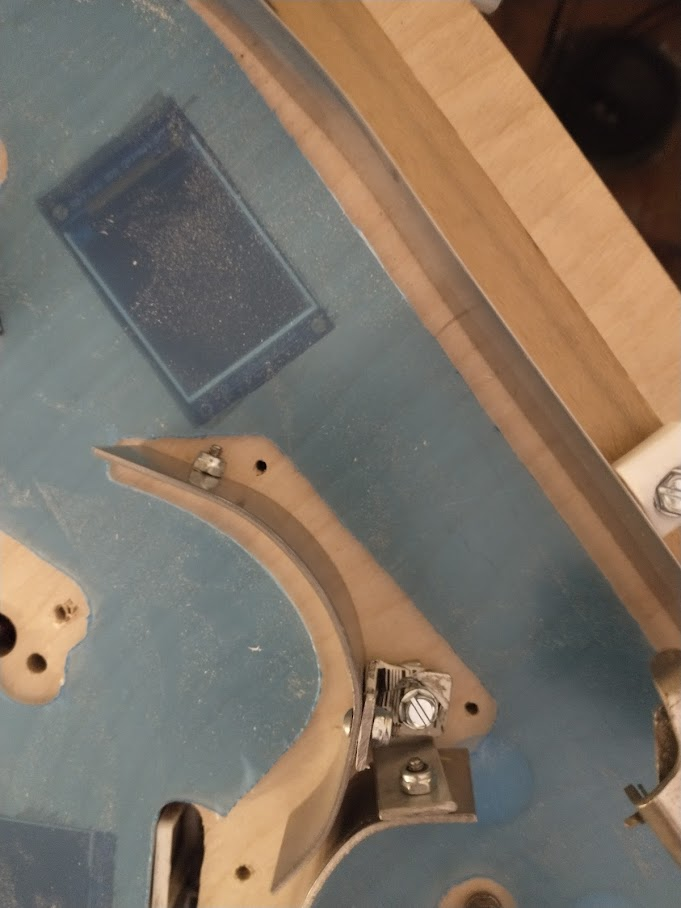

This is the guide for the upper left flipper. Old guide on the bottom. It had a split in it for a standup, but it turns out the flipper can't hit that angle. No matter how I aligned the eject plunger, I couldn't get a clean feed past that gap. So I made a new, one piece guide and installed it. Now the ball comes down nice and smooth to the flipper. Almost too fast, to be honest. I need to play with that mech a bit, see if I can get it to give a slower kick.

A bit hard to see here, but I added slots for adjusting the height of the left outlane posts. Eventually I'd like these to be slots in the wood too, with machine screw posts, so they can be precision adjusted, but right now the area underneath is too messy to safely install that.

The center post on the right side got a horizontal cut, since it can't really be moved vertically due to the feed from the shooter lane. Also replaced the upper end of the shooter/outlane divider rail with two mini posts. I'm not sure how that will affect the play in that area, but hopefully it does something. Previously it didn't seem like there was much to 'do' over there. You'd just watch the ball balance on the center post and fall one way or another, and any ball hitting the wood rail would just die and go down the outlane. So I'll see how this goes.

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

Finally got the lights all working, and coded a simple attract mode animation for them. Originally I was trying to use an existing server I found for controlling ws2812 leds, but it kept crashing and wasn't very suited for pinball animations, so I coded a simple server myself which just handles a light being on, flashing, or pulsing, with settings for frequency and phase. I think I will need to tweak my colors a bit though. Not sure if it's because of the specific leds I got, or the way the opaque white inserts are coloring it, but everything feels a bit 'pastel'...

The downside to doing all your leds as one giant strip, I guess, is that if you want to change them later it's more complicated. And of course, once I got everything together here, I realized I'd forgotten to install a light for the lower playfield diverter. So I guess at some point I'll need to cut a bit from my left over led strip, attach that there, then cut my existing strip somewhere, and run the data line over to the new led and back again.

I'm also thinking about maybe having a sort of 'wizard mode' accessible after you get all the main hands (at least straight, flush, full house, since technically those cover all the 'lower' hands too. maybe four of a kind, but it's hard to guarantee there's ever a deal with 4 of the same card), so it'd be nice to have a few more inserts in the barren center area between the screen+slings for that. Just when I thought I had all the lights/etc figured out!

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

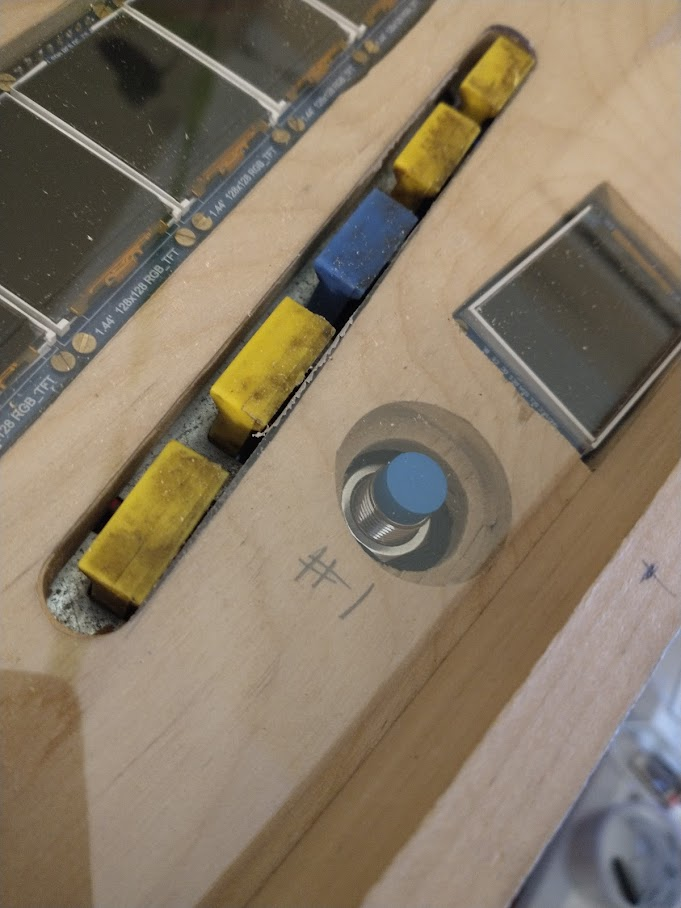

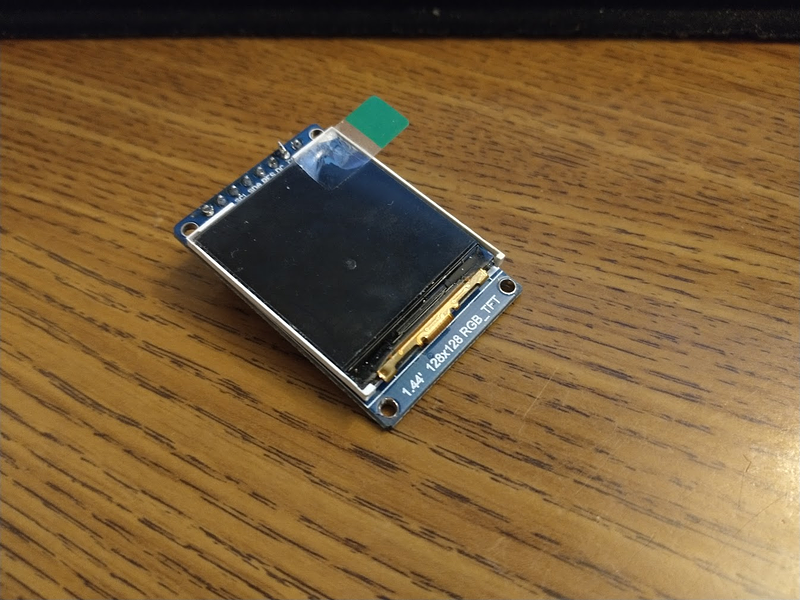

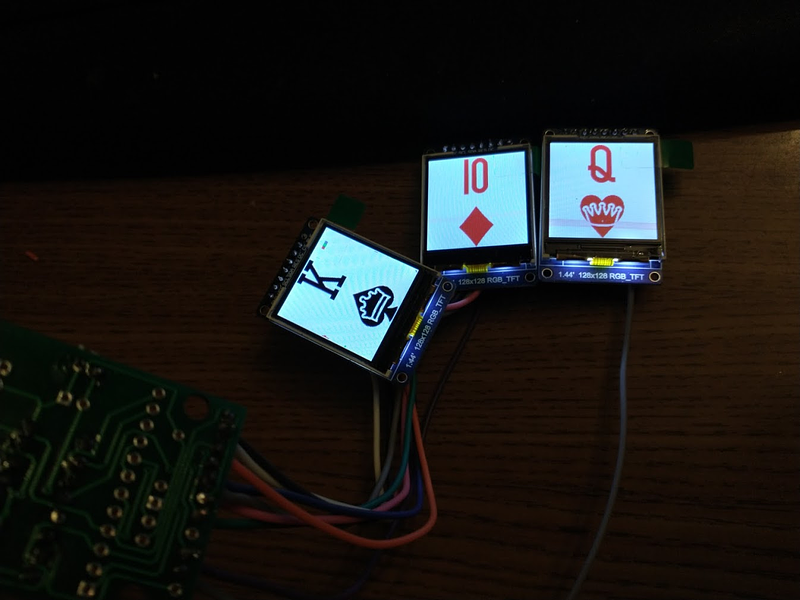

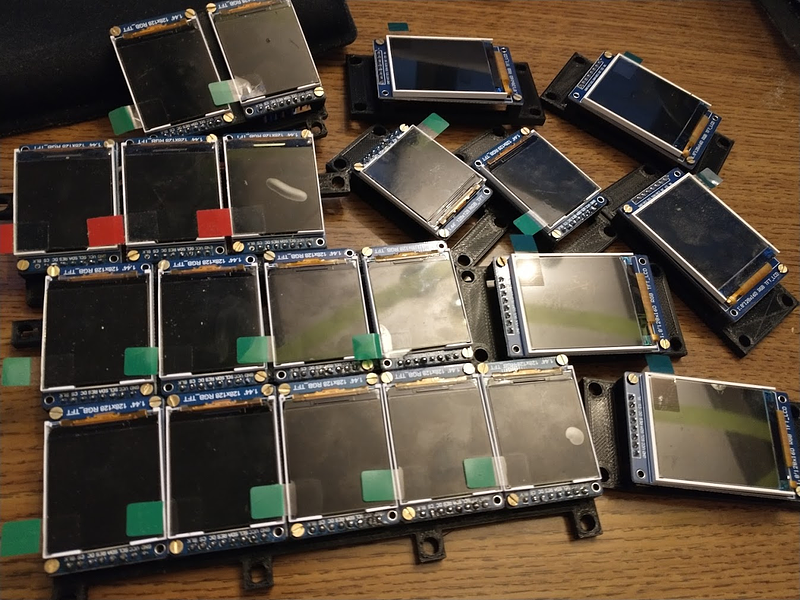

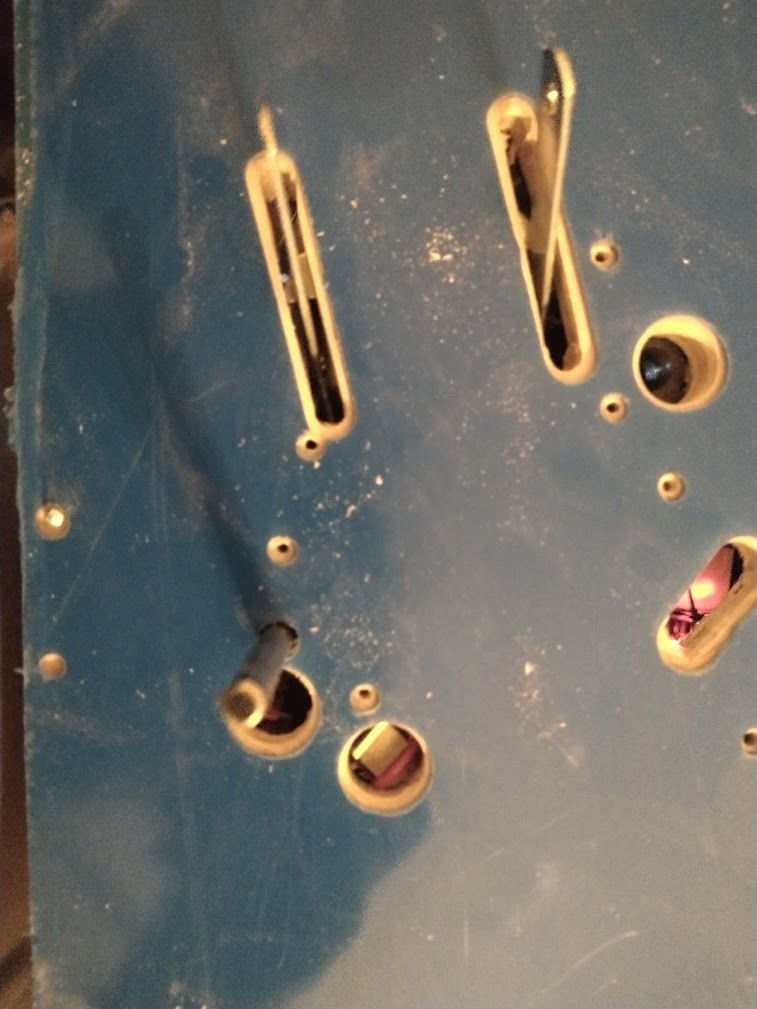

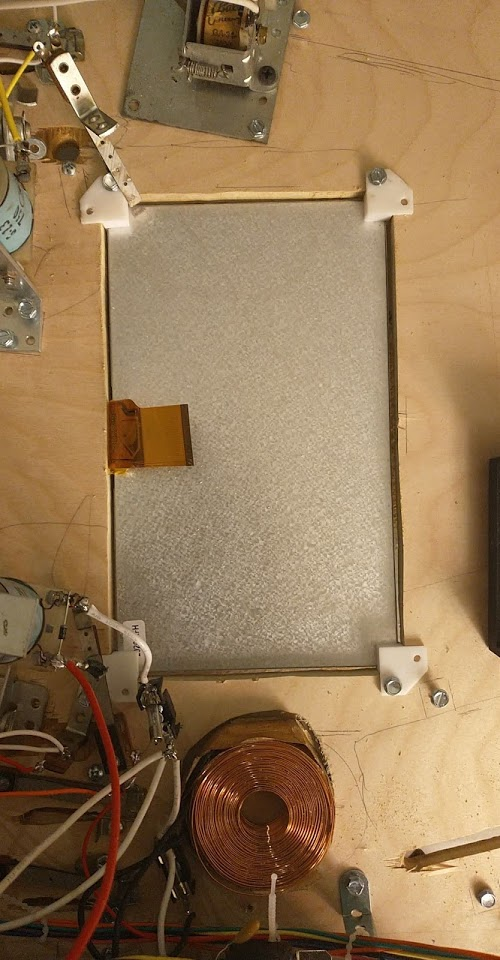

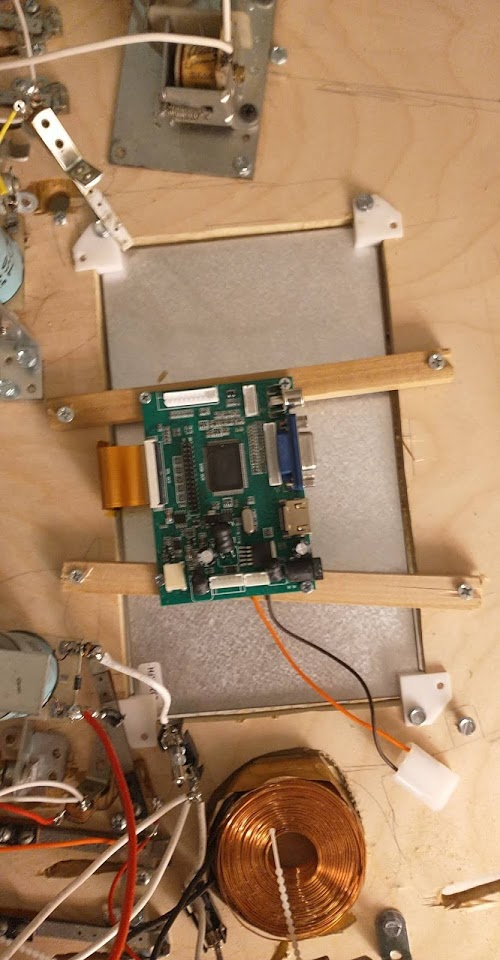

I'd been getting tired of using the projector for everything, and with the lights taking away half of its use, I figured it was a good time to get to work on the other part of that: the cards themselves. I'd realized early on that having all the cards just printed on the playfield, unchangeable, would have a possibility for people finding certain cards to go for every time which would make the game less fun, and having the projector able to deal a random set of cards onto the playfield solidified that worry. And then I found some cheap LCD displays on ali express while searching for the main screen I installed before

Turns out they were slightly narrower than the spacing on the drop targets:

Thanks to the provided example code it wasn't very hard to get one to display a card using a raspberry pi

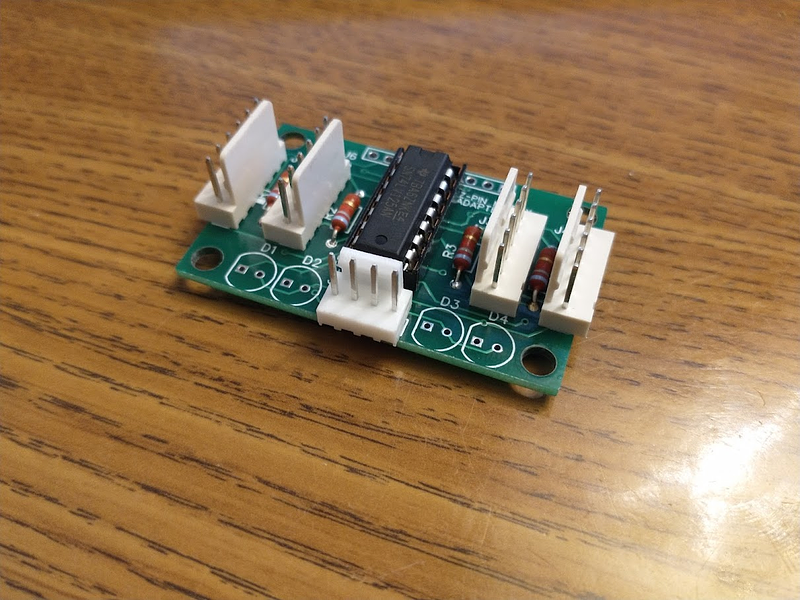

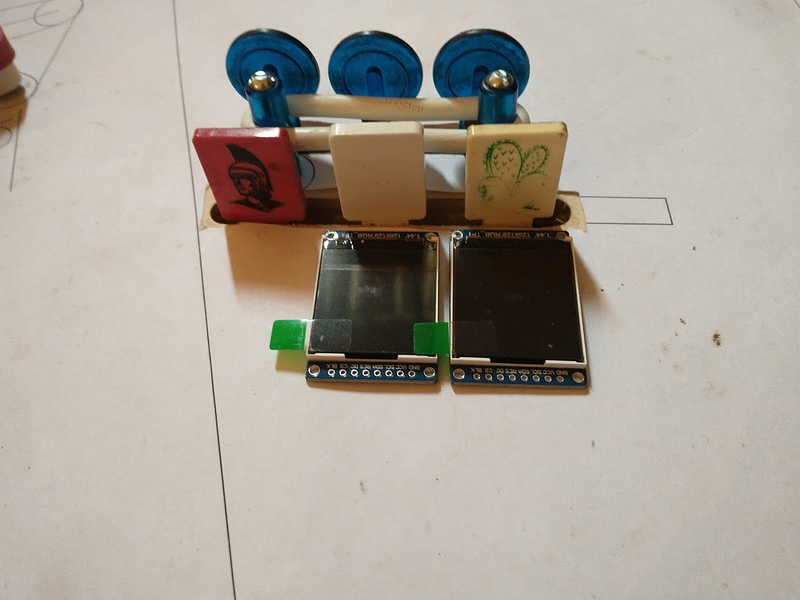

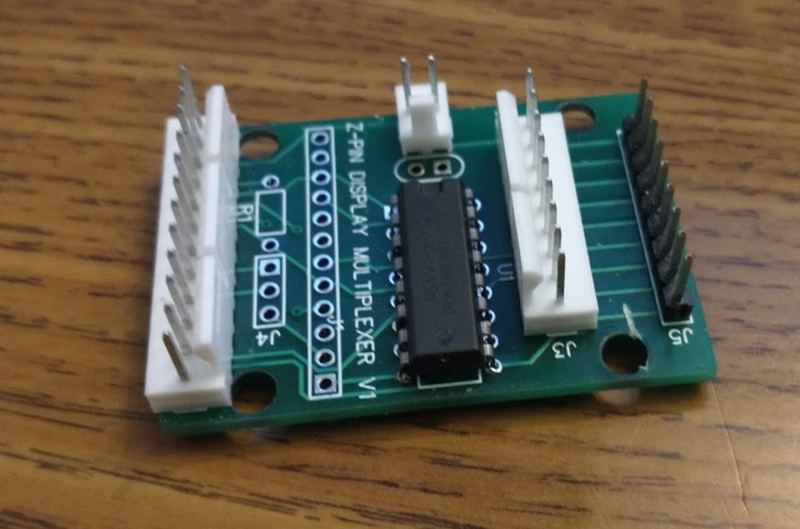

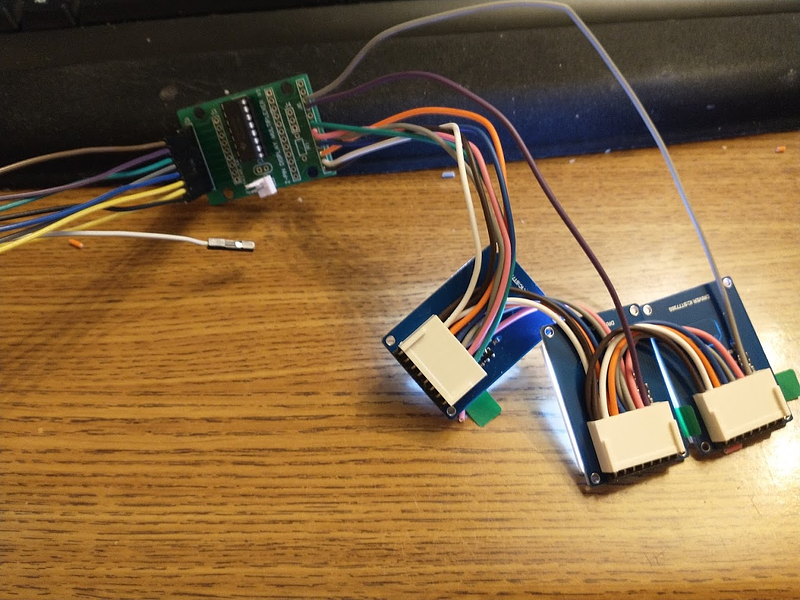

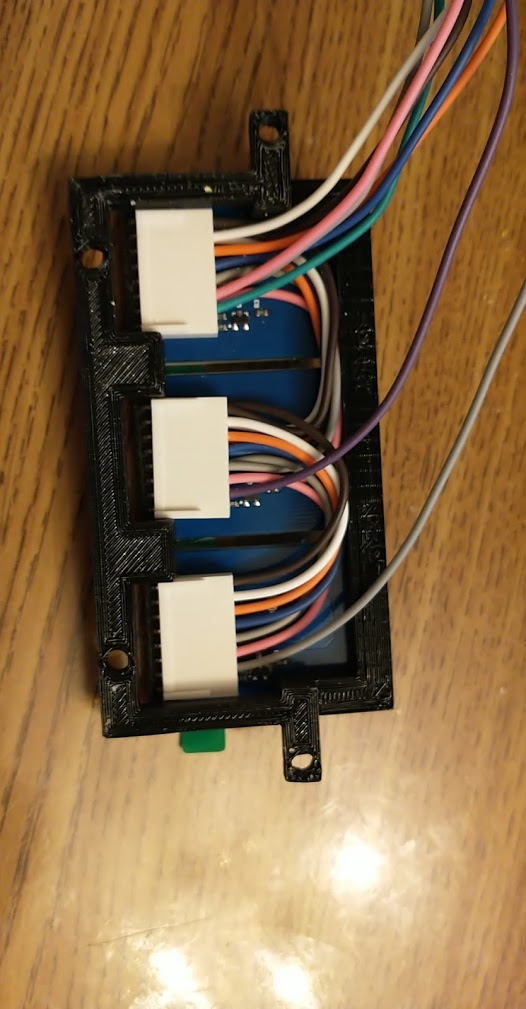

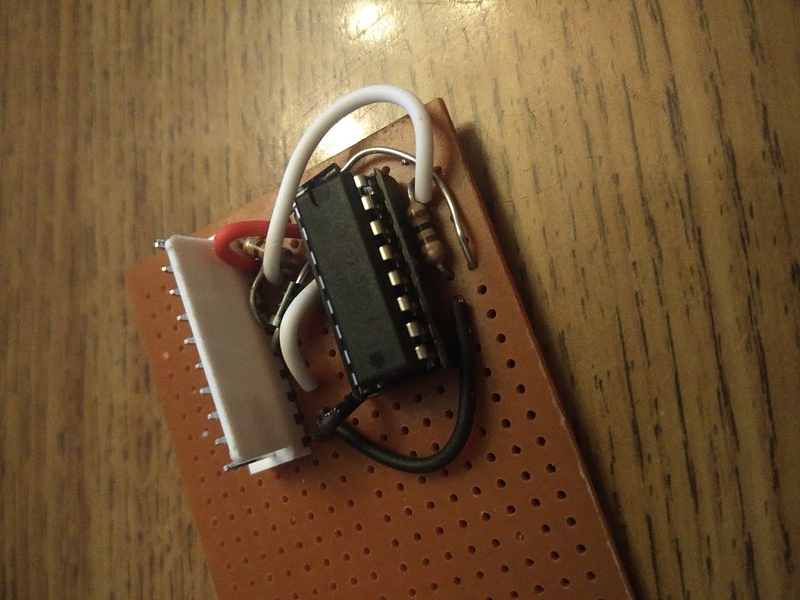

But could you drive more than one easily? I made a little board that had a shift register on it to control the CS line of the display, so that I could theoretically wire up to 8 displays to it

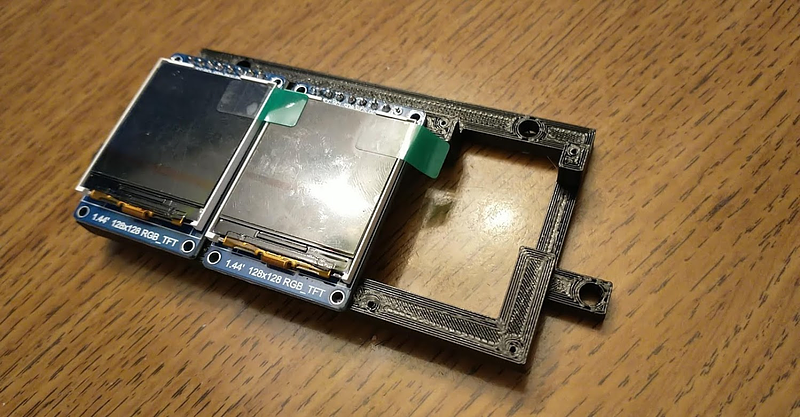

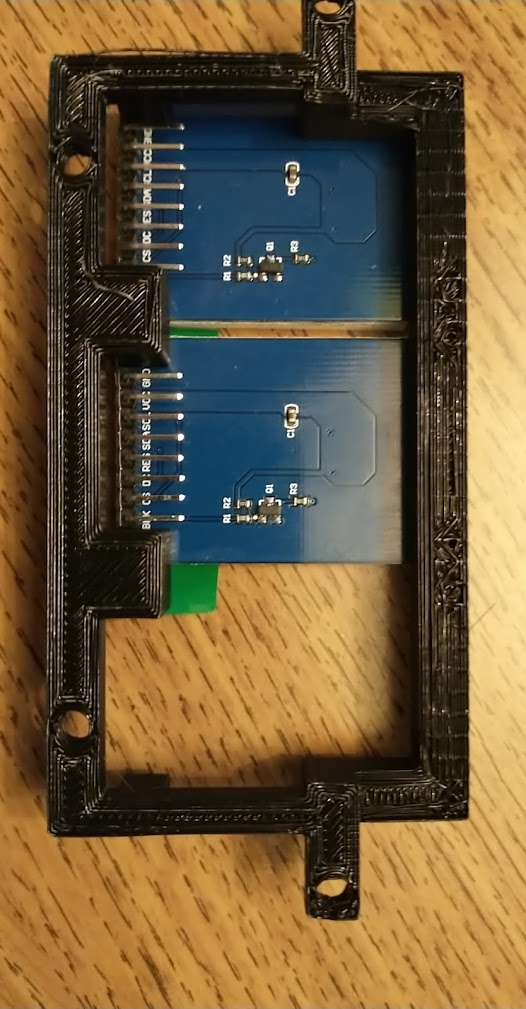

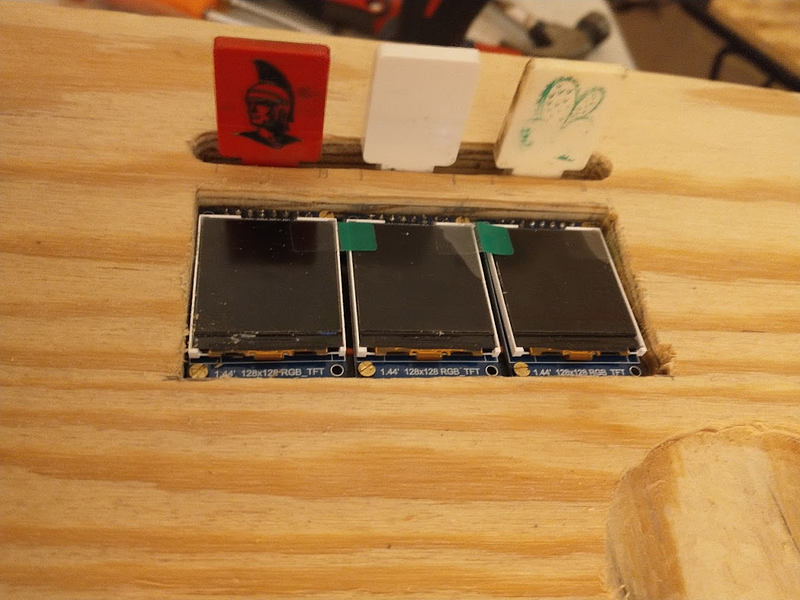

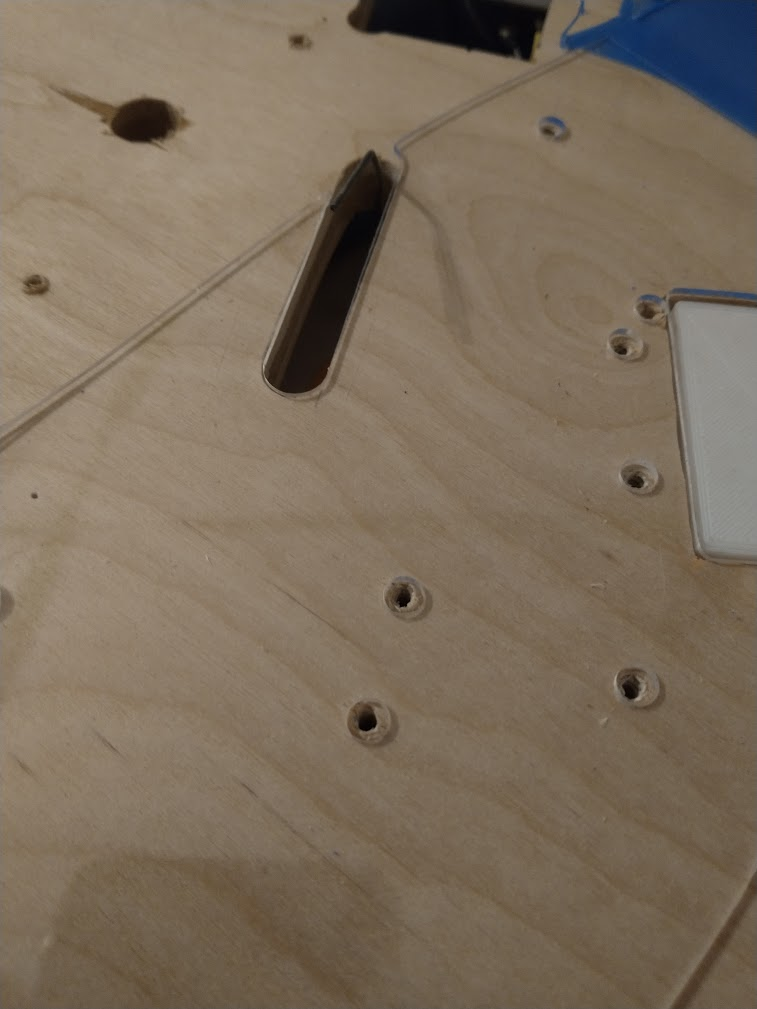

So far so good! Now, could I fit those displays in front of the targets? I did some measurements of the 3 bank in the middle and printed a bracket

And they fit! barely.

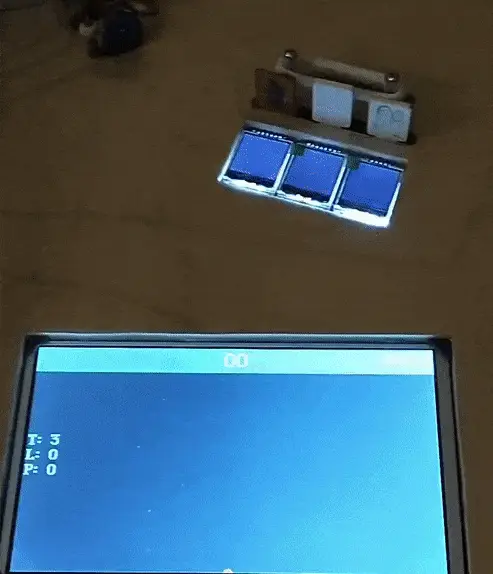

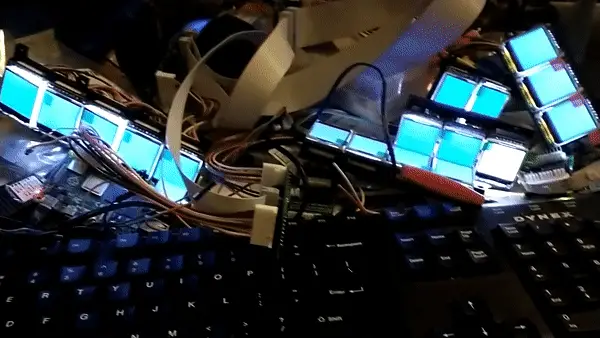

I programmed a simple tcp server to control them, and hooked the 3 displays into the game

Alright, proof of concept complete. Time to go way too far with this.

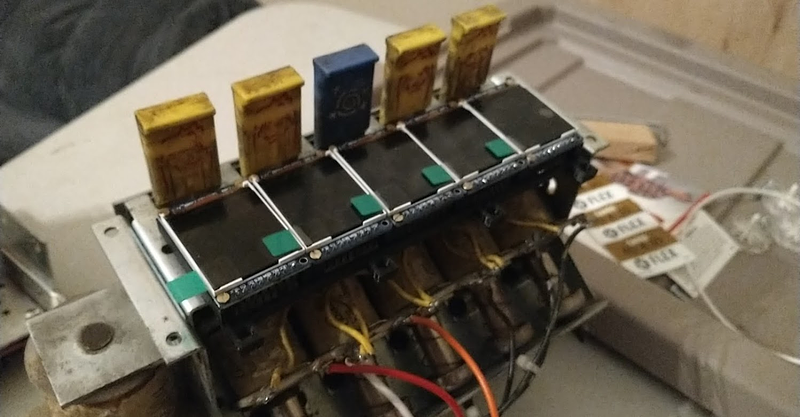

I'll need to custom make a bracket for every bank in the game, since they're all different manufacturers+sizes

And since I'm already getting into this, why not throw some other single displays around the playfield?

Now, can I actually drive them all? No. I lose signal around the fourth board. A lot of learning about signal integrity and I've got another version of my board with some termination resistors and a buffer chip to redrive the signal between each board

And with that, I can barely get all my displays to work

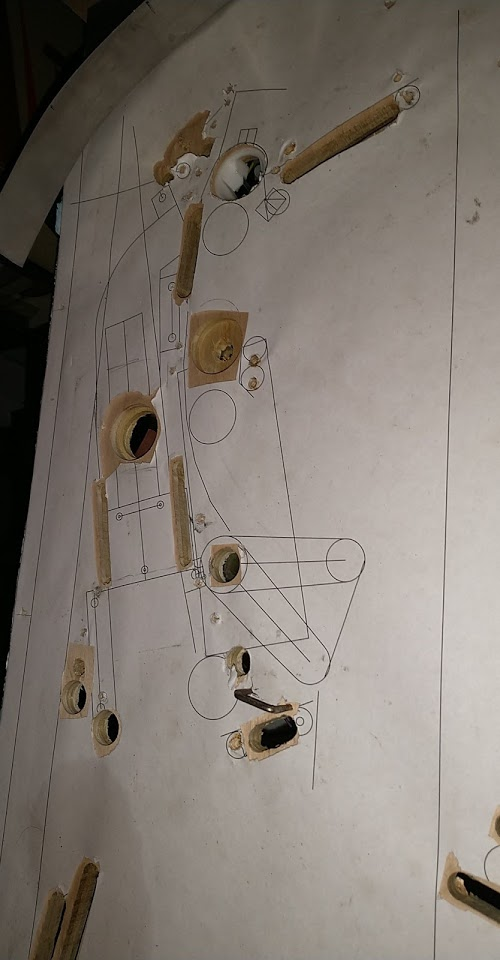

So I cross my fingers and cut a lot of big holes in my playfield. The amount of missing wood at this point is starting to concern me a bit, but it seems to hold up okay when the side rails are attached.

Wiring them up is also fun. So many ribbon cables! Almost looks like a Spooky game...

And once I finally got the whole playfield reassembed...

Success!

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

Still working on a bunch of stuff so I don't actually have any top side pictures yet but..... light!

The funny side effect of just trailing a light strip around the playfield is actually looks cool underneath too.

I ended up using 126 LEDs worth of 30/m strip to reach all ~30 inserts on the playfield. Besides from a few places where I didn't plan for lights and had too many mechs in the way, it was pretty easy to mount the strip over the the holes. The budget pack of clips I found are a bit too big, so there's still a bit of back and forth play, but I don't think there'll be enough movement to cause any issues.

I hooked the strip up to a dedicated 5v line+fuse coming from my ATX PSU, and it seems to be lighting fine with just that power coming in at one end (I was sorta expecting needing to provide more power somewhere along the length), even with all the lights on (which will never happen in practice). I had to make another little adapter board for my RPi-powered MPU to add in a 3V - 5V level shifter since the RPi only puts out 3V, but that seems to be fine for driving the whole strip, with an added 4ft of wire between the board and the beginning of the strip. Time will tell whether the electrical noise interferes with the lights once everything is playing, but hopefully they'll be okay (plus I plan to refresh them at 30Hz so any glitches should clear up quick).

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

Got the inserts from PBR, luckily they're the same size I was planning on, so I went ahead and cut all the arrows.

Midway through I stumbled upon this technique, drilling three holes through first, then routing out the rest using the guide, which allows me to do all the routing in one pass (before it was three passes since I kept needing to stop and remove all the dust, etc). Then once it was cut and the insert test-fitted, I'd take the guide away and hand route between the three holes to leave a good open area in the center for the light.

I was hoping that the circular inserts would match up with my forstner bits, but not all of them did. The smallest one (5/8?) are perfect, a nice snug fit, but the 3/4" are just loose enough that they'll fall out from gravity if there's any vibration. I'd like to get these all press-fit if possible so I don't have to worry about gluing them, so I'm going to try to make another router guide for the 3/4"

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

Got the LED strip today. Was surprisingly easy to get working using adafruit's python library, worked the first time. Sadly I don't want to use the python library so I'll need to explore alternatives for integrating it with the rest of the code. I did some experiments with inserts. The circular ones lit up fine, but the larger ones like the arrows had a bit of coverage issues.

It's hard to get good pictures of leds lit up, but

Here's a clear triangle insert

And here's an opaque one

The clear one lit up a bit more evenly, but it didn't really look that good, you could clearly see the hot spot where the led was located. Surprisingly I think the opaque one looked better overall, and other colors seemed less washed out, which is nice since that's probably my only option...

I then played around with led placement. Putting it more towards the center or ends didn't help much; the ends were still pretty dim. What did help was cutting a bigger hole. here's a single led, positioned similarly to the previous photo, but with almost all of the insert cut through the playfield instead of just one hole the size of the led

Probably good enough for me. I'll need to come up with a better way to cut those inner holes out, maybe another 3d printed router guide or something.

I also played with two leds under the same insert

This looks a bit better than just one, but not as good as I was expecting. The hot spots seem more pronounced. I'm not sure if I'll be able to position the strip to hold two leds inside the arrow or not (the clamps haven't arrived yet). This is where a lot of people seem to use multi-led boards, which might be worth it at least for the main shots? I'll have to look around

Cross posted from the original Pinside thread, this is one of many posts regarding my third homebrew pinball machine, creatively nicknamed 'P3'

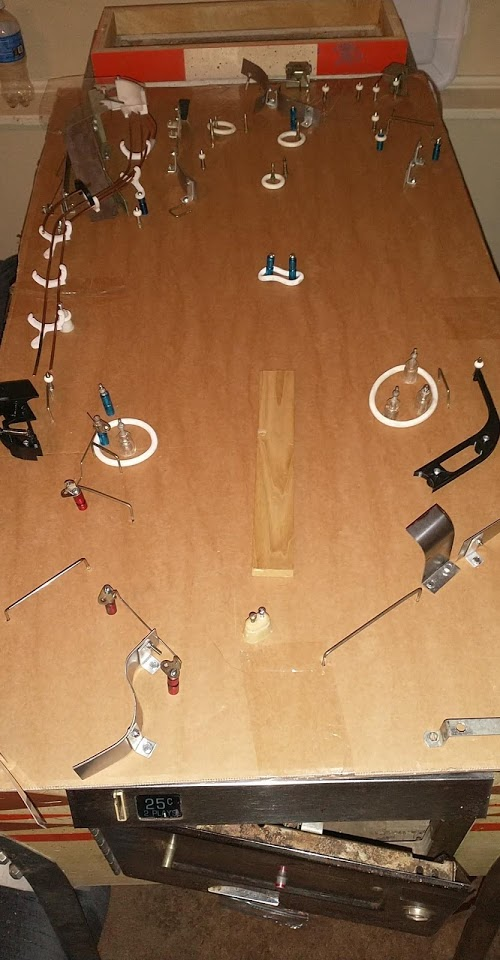

Since I had the playfield torn down, I figured I might as well install the inserts too. I've got a big bag of random inserts I've collected over the years from different stores, so I started laying them out.  To keep things simple, I used one size of arrow (1.5" triangle) and three circles. I think the circles can probably be done with a forstner bit, but the arrow will need to be done with a router. Taking some advice from